Serambi SYC punch press presisi krahang dua terbuka (110-315T), mesin cap untuk logam

Kaperngan Produk

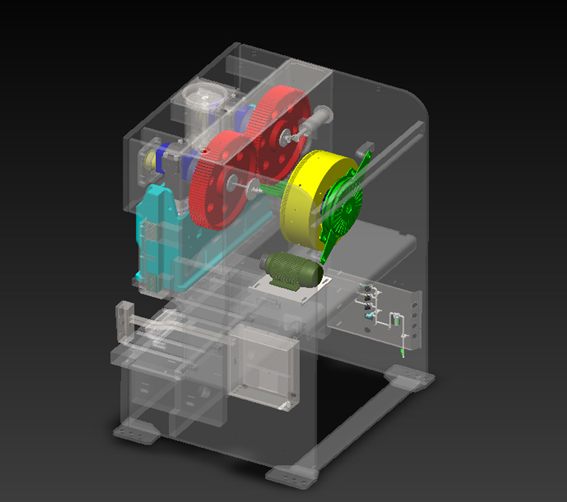

Seri SYC Tipe Terbuka Double Crank Pres Pukulan Presisi (110-315T)

Fitur Produk:

1. Tubuh mesin dilas dari bahan berkualitas dan diolah dengan penghapusan tegangan, meningkatkan stabilitas dan keandalan presisi mesin.

2. Untuk menjamin mesin berjalan stabil dan lancar, menggunakan desain dua papan slida simetris dengan balancer.

3. Presisi penyesuaian cetakan hingga 0,1 mm, aman, terpercaya, dan praktis.

4. Poros engkol, gigi, dan batang penghubung dikeraskan oksidasi dan dihaluskan, memiliki performa mekanis komprehensif yang sangat baik dan fungsi tahan lama.

5. Desain struktur yang rasional, memudahkan produksi otomatis dan produksi jalur.

6. Menggunakan kopling/rem intensitas tinggi yang andal dan katup elektromagnetik ganda, pelindung kelebihan beban dapat menjamin produksi yang aman secara keseluruhan.

7. Mengadopsi katup solenoid ganda yang aman dan perangkat perlindungan hidraulik kelebihan beban untuk memastikan keamanan produksi dan operasi.

8. Cetakan mampu menahan beban dampak besar serta pemipaan cetakan eksentrik.

9. Menggunakan rangkaian listrik loop tertutup, kompatibel dengan peralatan otomatis apa pun.

Satuan Standar:

Kopling kering & rem

Sistem operasi standar

Pilihan mode operasi

Pelindung kelebihan beban hidrolik

Konversi frekuensi

Detektor overrun

Dorong 2-tangan portabel

Katup solenoid ganda

Perangkat penyesuaian sorotan otomatis

Indikator ketinggian cetakan digital

Sistem pelumasan otomatis

Penghitung total, 6 digit

Penghitung preset, 6 digit

Penghitung pemeliharaan, 6 digit

Penghitung umur, 6 digit

Sakelar kamera putar elektronik

Perangkat peniup udara

Sumber air reseptakel

Lingkaran pendeteksi missfeed

Reseptakel daya

Opsional:

Bantalan cetakan

Kurain cahaya keselamatan

Perangkat pengeluarkan slaid

Lingkaran pembalik motor utama

Tombol kaki

Blok cetakan keselamatan dengan colokan

Katup solenoid ganda dengan Inverter

Pendeteksi missfeed

Rem pengereman

Sistem ganti mati cepat

Clamp cetakan Atas/Bawah

Lifter cetakan, Lengan cetakan

Perangkat penyedia otomatis

Penyusun NC penyedia (3 dalam 1)

Penyedia roller NC

Straightene

| Spesifikasi | Satuan | SYC-110 | SYC-160 | SYC-200 | SYC-250 | SYC-315 | |||||

| Model | V | H | V | H | V | H | V | H | V | H | |

| Kapasitas | Ton | 110 | 160 | 200 | 250 | 315 | |||||

| Tingkat tonase | mM | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Gangguan | mM | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 300 | 170 |

| Gangguan per Menit | g.g.m | 35-65 | 50-100 | 30-55 | 40-85 | 25-45 | 35-70 | 20-35 | 30-60 | 20-35 | 30-50 |

| Ketinggian cetakan | mM | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 615 |

| Penyesuaian slaid | mM | 100 | 100 | 120 | 120 | 120 | |||||

| Luas slaid | mM | 1400x500x70 | 1600x550x70 | 1850x650x95 | 2100x700x95 | 2100x700x95 | |||||

| Wilayah Bolster | mM | 1800x650x130 | 2000x760x150 | 2400x840x170 | 2700x900x170 | 2750x900x190 | |||||

| Motor utama | kw.p | 11x4 | 15x4 | 18.5x4 | 22x4 | 30x4 | |||||

| Tekanan udara | kg/cm 2 | 6 | |||||||||

| Menekan presisi | GB/JIS kelas 1 | ||||||||||

| Ukuran penekan | mM | 1745x2000x3059 | 1940x2200x3709 | 2235x2620x3849 | 2545x3000x4304 | 2545x3010x4689 | |||||

| Wilayah efektif bantalan cetakan | mM 2 | 350x235x2 | 410x260x2 | 540x350x2 | 640x470x2 | 640x470x2 | |||||