Praecipuus fabrica instrumenti instrumenti instrumenti ferrarii domus Lihao Machinery consuetudo continua moriendi feliciter integravit et systema torcularis impressit in suam lineam productam ad altam praecisionem fabricandis laminarum connexionis ferrariae. Haec solutionis formandae solutionem efficientiam producendi signanter emendavit, dum in tuto collocatur uber qualitas et praecisio, cum accurata postulata domesticae industriae industriae occurrens.

challenge:

Lorem ante provocationes in producendo laminas conexionis altae praecisiones ferrariae ad adjumenta domestica, ubi strictae accuratae dimensionales et summus voluminis productio requirebantur. Traditional alea consilia insufficientes fuerunt ad occurrendum sistens implicatas exigentias partium, quae ducens ad qualitates potentiales et rationes exigui altiores. Lorem exigebat consuetudinem continuam moriendi et premendi rationem, quae efficaciter partes altas accurate producere posset, dum operandi sumptibus et materialibus vastitatem extenuando.

Solutio:

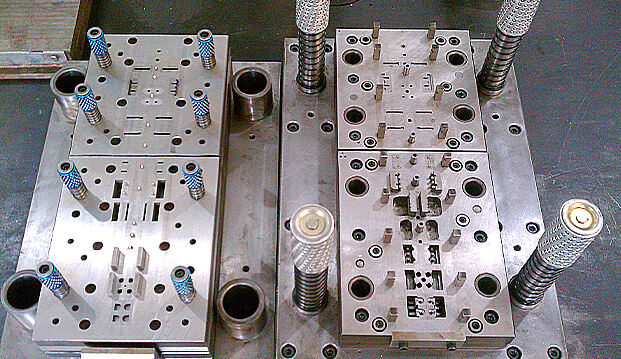

Lihao Machinery morem continuum mori praebebat, adamussim constituebat ut multiplices operationes in uno cyclo tationis exerceret. Hoc non solum perputationem emendavit, sed etiam accuratissime servavit, extenuando materiam vastitatis et temporum cycli minuendi. Alea par erat cum pressione pressa nativus systematis optimized pro certis exigentiis partium, stabilis pressionis et certae materiae per processum pascendi procurans.

Postquam alea producta est, turma Lihao Machinery opera arctissime laboravit cum emptori ad iudicium deducendum et servandum currit. Per subtilem impressionem calcationis, velocitatem pascendi, et parametri perficiendi, Lihao Machineria procuravit productionis processum stricte requisita accurationis et efficientiae emptoris occurrens. Prosperum iudicium decurrit ad productionem massam lenis et laboris optimized.

Key Features:

Custom Continuous Die Design: Designed specifically for the customer's hardware connexion plate production, continuum alea peragit multiplices operationes in uno cyclo stampando, augendo efficientiam et deminutionem temporis.

Perfecta Integratio cum Press Stamping: Lorem torcularis systematis cum continuo moriatur plene integratur, dum accuratam potestatem pascendi celeritatem et pressionem pressit, accuratam partem dimensionum et constantiam procurans.

High Precision and Efficiency: Systema optimized variationes dimensivarum minimizat, ex parte qualitatem constantem procurans, et signanter meliorem altiore productionis celeritatem dum materiam vastitatem minuit.

Velox Prototyping et Iudicium Currit: Lihao Machinaria turma directa operata est cum emptore ad iudicium exercendum currit et processum parametri accommodet, dum systema occurrit requisita productionis et eventus optatos in minimo tempore assequendos.

Capacitas productio aucta: Integrando morem moriendi et premendi premendi rationem, emptorem augere capacitatem productionis, reducere tempora cycli, et impensas operationales inferiores, augere aemulationem in mercatu domicilio.

Results:

Integratio Lihao Machinery consuetudo continua moriatur et systema diurnariis permissum est emptori provocationes productionis superare et ad altas postulationes domus appli- nationis industriae occurrere. Systema conservavit subtilitatem laminarum ferramentorum connexionis, exiguo minuendo et efficientiae meliori. Per streamlining processum productionis, emptorem reducere sumptus fabricandi, tempora plumbea minuere, et altiore producti qualitate emendare potuit. Lorem expressit magnam satisfactionem cum solutione Lihao Machinery nativus et perennem technicam sustentationem, consilio utens Lihao apparatus machinationis ad futurae productionis necessitates permanere.

Hoc casu elucidat Lihao Machinery peritiam in tradendo morem moriendi et solutiones premunt pro summus praecisione, summus volubilis fabricandi in domum appliance sector, ut nostri mos successus in a competitive foro.