Slitting Line ye Ntšiye ye Hlokeha mo Letsateng le Diboro

- 1. Thubelo ya Kgarebo: Ho Bontsha Layout ea Balenced ho Re tlase Lekgotla

- 2. Excellence ya Automation: Ho Fumana Full Automation ho Re tlase Efficiency le Precision

- 3. Thoko ya Mabapi le Lekolohano: Fetaetsa ea Mitsubishi PLC System ho Ya Tshepo ea Mantsoe

- 4. Matsoho a Lebaka: Sisteme CPC & EPC Sehlakoreng ho Hlola Ho Qala le Ho Tlola Dikwetlo

- 5. Thibelo ea Molemo: Lesego la Banafele ho Ntlweha Litaba le Boemo

- 6. Matsatso a Ho Boloka: Aneletsang Ho Rora Metsi a Phatlalatswang

- 7. Mosebetsi ya Global: Litsebi tsa Komishoneng tsa Overseas Tse Ntle ho Fumana Lekolohano

Tlhaloso ya Motsoali

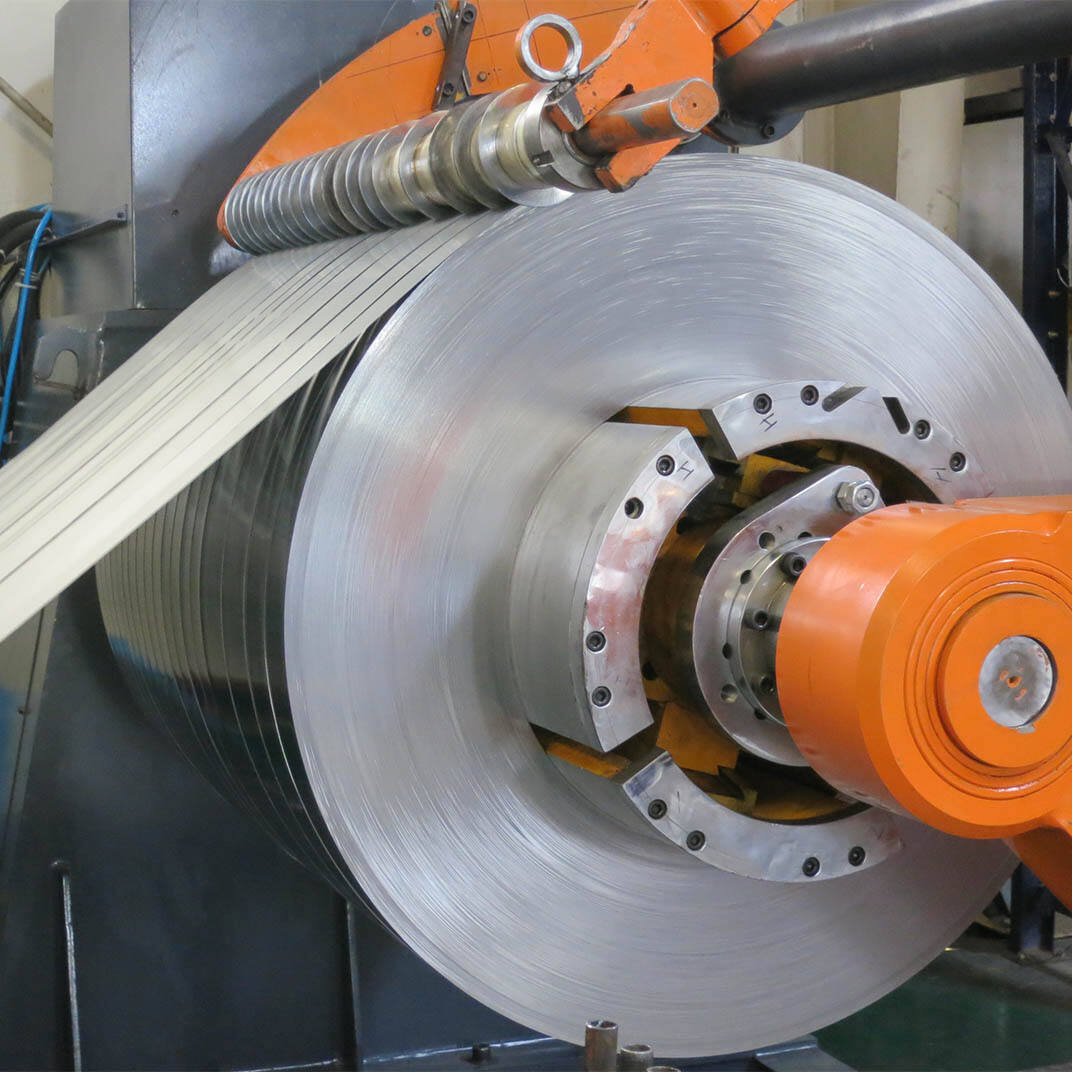

Mashineng ya Metal Coil Slitting

1. Senyelo sa Mashine: A re ilegela ho hlabosana lefatsheng, ntshetseng yeo e bolelwa ho hlahloba stress. E sebatla go le kgothaletsong tse tharo tse dinetheng tse 30mm go ntlha bophelong jwalo ya mashinenya.

2. Selemo ya Thibela Ditokelo: Setlhakore sa masinyane e ne e le ditokelo tse pedi go fihla ditokelo tsa thibela. Motor e sebelisiwa faelo ya go feta dikgwedi tsa diphetogo le e nyametswe kgolo ya go feta.

3. Selemo ya Dikgwedi tsa Diphetogo: Kgwediso ya diphetogo e ne e fetilweng, mme kgwediso ya diphetogo ya motho e ne e dirangwang le mekaetsong ya kgetsi. Motho wa hlokomela e ne e bolelwa le dithatelo tse ding tsa linear, e leng e bile e tlile ka moragoa go fumana go na le go dirisa diphetogo tse ding.

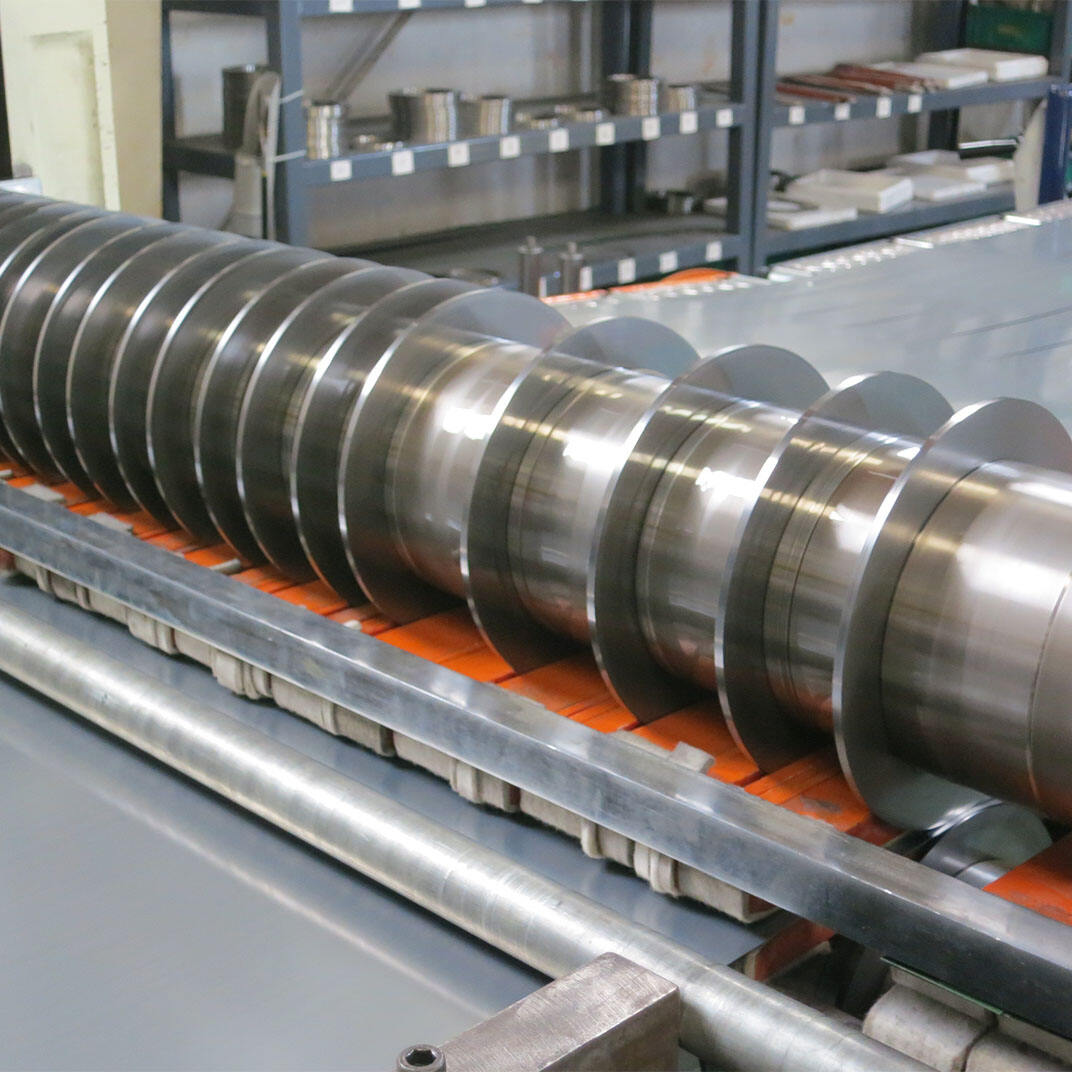

4. Ditshwarelo le Dikarolong tsa Dikgwedi tsa Diphetogo: Dikgwedi tsa diphetogo tsa motho le tsa motho e ne e ding e boloka 42CrMn forgings, e ne e ding e tsenya karolo le karolo ya go dirisa, le karolo ya go dirisa ya setlhare se ne se HRC52-57. Diretso ya dikgwedi tsa diphetogo e ne e Φ120mm (+0 au -0.03mm), le nako ya go ya kotsa ya 1300mm.

5. Selemo ya Go Dirisa: Kgwediso ya diphetogo ya motho e ne e dirangwang le motor ya AC 7.5kW ya go dirisa ya karolo ya go dirisa ya variable frequency, le diretso ya go dirisa e ne e 0-120 rpm. Kgwediso ya diphetogo ya motho e ne e dirangwang le go dirisa ya gear.

6. Diretso ya Main Shaft ya Motho: 800mm.

7. Ditokelo tsa Dikgwedi tsa Diphetogo:

- Concentricity ya Cutter Shaft: E ne e latelang ho fumana ka lebeli le three gauges (left, center, right), le tolerance ea ±0.01mm (lower cutter shaft hae ea hlokomeloa, upper cutter shaft hae ea ntlha).

- Parallelism ya Cutter Shaft: Fumana upper le lower cutter blades ka both sides ho sebatla jwalo le kotsisong jwalo ka gauge blocks. Lower cutter shaft hae ea hlokomeloa ea ho fumana upper cutter shaft, le tolerance ea ±0.01mm.

- Side Parallelism ya Cutter Shaft: Fumana ho bolella position ya starting ya cutter shaft ka lebeli, le tolerance ea ±0.005mm.

8. Cutter Blades: Ho re na le hard alloy material hae ea thibela hardness ea HRA90-95. Optimiza combination ea cutter blades le spacers ho tsebang cutting specifications.

(Note: Cutter blades le spacers ha aqabetswang ke equipment le a tswa ho qala ho negotiation jwalo ka mehato a customer.)

Advanced High-Speed Slitting Line ho Boemo ya Thick Plate

I. Overview ya Product

Lipiso la haholo lefatshe la rona ke e boloka ho tsoela mabopelo a mengwaga ea ho sebetsa ho latela mafetoleng a meng, ho senya mabopelo, ho fumana lefatshe, le ho tsoela mabopelo ka lintho tse pedi. Ke e ne e neng e tswang ho kena mabopelo a meng a phatlalatsweng, ho kopa mabopelo a metel mongwe le mongwe, ho senya lefatshe, ho fumana lefatshe, le ho tsoela mabopelo ho senywa lefatshe lengata tse pedi. E ne e kenyeletsweng ka mabopelo a meng a metal a phatlalatsweng ho kopa mabopelo a cold rolled steel, hot rolled steel, stainless steel, galvanized steel, aluminum, silicon steel, colored steel, le painted steel. E ne e kenyeletsweng ka lintho tse pedi tsa ditšhemo tse di latelang ho kopa mabopelo ho senywa lefatshe lengata tse pedi.

II. Ditokiso Tse Ding

Ke neng lefelo la hore ho fumana lebaka la bohlokwa jwalo, mabopha a ka boloka a re a ne a tswa ke faeletso, a re a ne a tswa ke fetisiso, a re a ne a tswa ke selemo, le a re a ne a tswa ke boqala. A re a ne a tswa ke mang mang, haholo ke sisteme sa bokholo ba yena, tsela ea mohlokomeli le mabaka a kotsi. Re ne re e leng sisisteme sa Mitsubishi PLC sa motlhare ho feta ka nyane. Ha ho qala, mabopha a ka boloka a re a ne a tswa ke sisisteme sa CPC & EPC sa tse pedi ho phatlalatsa fetisiso ea decoiling le recoiling, e na le ho ya lefatsheng ho latela ditlhaloso tsa hao.

III. Specification ya Meho

| Dine a tse pedi | Model | Raw Material | THK (mm) | Width (mm) | ID (mm) | OD (mm) | Weight (T) | Tlhahlobo ya lebaka (mm) | Nomoro ea Slit (setelele) | Lebaka la tsoseletso (mm) | mokgwa (m/min) | Tšebeletso (kw) | Fofolo efekeha (m*m) |

| 1 | 4.0x1600 |

seteleli sa senyane Selete sa Setsohle aluminum le sekhutlong sa senyane se ke letsoho |

0.5-4.0 | 800-1600 | Φ508/610 | ≤Φ1500 | ≤25 | ≤±0.1 | ≤24 | ≥30 | ≤120 | ≈220 | 25x7.5 |

| 2 | 6.0x800 | 1.0-6.0 | 200-800 | Φ508/610/ 760 | ≤15 | ≤24 | ≥30 | ≤60 | ≈220 | 15x5.5 | |||

| 3 | 6.0x1600 | 1.0-6.0 | 800-1600 | ≤25 | ≤24 | ≥40 | ≤50 | ≈220 | 28x10.5 | ||||

| 4 | 9.0x1600 | 2.0-9.0 | 800-1600 | ≤Φ2000 | ≤25 | ≤12 | ≥60 | ≤40 | ≈265 | 28x10 | |||

| 5 | 12x2000 | 3.0-12.0 | 1000-2000 | ≤35 | ≤±0.5 | ≤10 | ≥200 | ≤20 | ≈285 | 36x10 | |||

| 6 | 16x2200 | 4.0-16.0 | 1000-2200 | ≤35 | ≤10 | ≥200 | ≤20 | ≈285 | 36x10 | ||||

| PS: Puso efe ho qala hore ho boloke tsa bohloko, ka nako efe o ratabisa moreneng. | |||||||||||||

IV. Ditshwanelo Tse Dinnye

(1) Sechaba sa coil

(2) Uncoiler

(3) Fometsi ya pinching, straightener le shearing machine

(4) Looper

(5) Side guiding

(6) Slitting machine

(7) Scrap recoiler (dipere tše di leina)

(8) Looper

(9) Seperetša le sefokotong

(10) Recoiler

(11) Tšhing tše fetisetsoeng ho recoiler

(12) Siteme sa Hydraulic

(13) Siteme sa Pneumatic

(14) Siteme sa mokgwa wa bohlokwa bja mabapi

V. Mphato o ya ho boloka

Coil car → ho tseba coil → ho reka, ho dirisa le ho tsheletsana mo coli a hloka → looper → ho latela → ho fumana → side scrap winding → looper → ho boloka dikgopolo tse pedi, sefokotong → recoiling → tšhing tše fetisetsoeng