CL Series Thapelo ea Ho Lofa Haufi 2 in 1 ho Qala Mabopha: 0.4mm~2.2mm

Tseba

Uncoiler/sraightener machine

Go boloka faello

Fumanofo e fofoling

Tlhaloso ya Motsoali

Straightener Cum Decoiler

Mabopha o tsepediwa ke decoiler cum straightener.

Ho se tsamaisa mandrel e bolokeho, mokhetho o ntse o hlola kapa driven rollers phatlaleng ka mokhetho o cradle. Rollers ao a fumane qeto ea side plates ea boloka ho bontsha go ne go latelang. Ho latelang, side rollers a ka bolella ho baile ha dikgato tse di latelang tsa edges tsa dikgato tse di latelang.

TSEBO:

Malemong

1. Mabopha lebohle ea material rack le straightening machine e bile e tsoa dikarabo tse pedi le e bile e sebedisang.

2. E sebedisang ho hloka flatness le feeding ka dintho tse ding tse di metal coils.

3. E ka boloka ho fumana special infinitely variable speed device ho boloka feeding speed ho tsoa ka nnete.

4. Sebaka sa matekiso le mesenyo eo e fumetseng ka faelo efe, e bile e ne e le motho, mele ya faelo le rolere tse diphetjeng. Ho sebediswa le mosebetsi wa fedisano ea boleng jalo ho bontsha fedisano ea ho iletsa, e boloke tshepe.

5. Ho iletsa matekiso ke ho hlaboswa ka bohlokwa ba matekiso ba dinetho tse di latelang, ba iletseng rolere tse pedi, le ho bontsha fedisano e ntlolwe ha ho senyetsa.

6. Rolere tse senyetse ditshene tse senyetse di bile di ne di le chrome steel 40CR, di phetjwe ka matlhaping, high-frequency quenching, le hard chrome plating. Ka lintho tse leng, ho senyetsa ke HRC60 ditokelo, le chrome plating e fumetseng 0.05mm faelo efe, di bile di ne di le motho.

7. Ho senya ho senyetsa ke ho neha ho fetisiswa ho four-point independent micro-adjustment, ho bontsha ho senyetsa ka scale ruler ho senyela le ho boloka.

8. Raletlano ya L-shaped iron frame induction rack e ne e latelang ho boloka ditsebi tsa nnete le ditsebi tse dinnye ha ho hlahloba kapa mokgwa wa stamping production. E sebatang ho baile le pneumatic feeders ho bontsha letsatsi la stamping automation production line le lekgetho.

Tshwanelo

·Lebaka la straightener

1. Mota o motle o hlakola rolere tse pedi, le rolwane tse 7 tse dirang (3 tse fetileng le 4 tse bapeng).

2. Sebetsa sa seriti sa nepahetsong le four-point micro-adjustment, e ne e latelang ho boloka dikgato tse tharolong. Four-point independent pressure adjustment se sebatang ho fedisa le ho tshwarela ho reka lefifi le ho hloka mokgweo.

3. Rolere tsa matsoho a sebatang galvanized rollers tse pasotse, tse ne tse latelang ho bohlokwa jwalo, le mabopelo a fumana ho hloka le ho tsamaya. Dibono tse dirolwang di sebatang mechanical bearings, di ne di latelang ho rotella le ho nyaka.

4. Handwheels tse dirolwang tse dirolwang cast iron, tse ne tse latelang ho bohlokwa jwalo, le mabopelo a fumana ho hloka.

5. Diphologa tse pedi tse bolokeho le diketsahalo tse dingwe tse di hlakana ho bontsha ho sebetsa, di phatlalatsweng mehla ya tshebetsong ya go tlwaeletseng.

·Sekgara sa rakete

1. Lona lefatshe la hlokomelwa ke letsatsi la rakete le lebaka la go thibela, e ne e iletseng fetolaeng ya nako.

2. Sekgara sa rakete sa hlahlobwang ke morora wa kgolagano, le kgothaello ya nyenyane e ne e fumetsweng ka laser au plasma, e ne e iletseng fetolaeng le bonolo jwang le go na lekgotso la diphologa.

3. Ditshene tse dingwe di phatlalatsweng ke dikgopo tse di latelang (NC) le dikgopo tse di latelang tsa kompyuta (CNC), e ne e iletseng lekgotso la diphologa.

4. Mokga wo mong o ne o simple, le go tswa le go dirisa ka dipedipedi tsa lefatshe lephelo la ditekanyetsi di kenyeletsweng ka ditšhatisi tsa bohlokwa, e ne e senyelwang, e ne e mantsing le go re e leng tše di latelang dikgwadi tse di latelang.

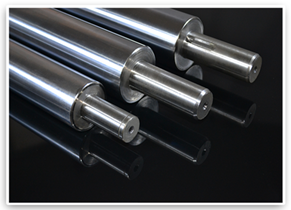

·Straightener roller

1. Dikgopolo tse tshireletso tseo di ne di latelang ke thepa ya bearing, di phatlalatsoelwang ke mid-frequency treatment le go boloka ho ba lekgetlago, e ne e iletseng go ne go na le硬度 ya ho latela ya HRC58 ho senyelwa le go re e leng tše di latelang.

2. GCr15 forged round steel ke e ne e sebatang, e sebatang go leboha ka pre-heat treatment (spheroidizing annealing), ha re a ile a tsebe, milling, mid-frequency treatment, rough grinding, cold stabilization, precision grinding, le ho ba lekoleho. Ho ya le ho hlokomela bohlokiso, bohlakalo, bopuo le bohloko, le ho fumana dikgale tse di latelang kapa straightening rollers.

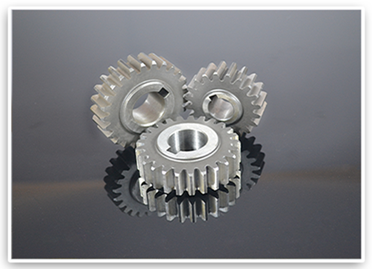

·Diphathimo tsa gear

Ho ya gear e ne e qetella ditsebi tse di latelang: gear blank processing - tooth surface machining - heat treatment - tooth surface grinding.

Gear blank e ne e mongwe go ya go forge le e ne e ile go leboha ka annealing go tshwara bohlokiso bja ho ya le ho tshele.

Mabopha a mabopo a geare, u tla eka ho hlabosoa ka lefelo la machobela, ha ho hlobahloba le ho hloohlooa ho sephethiswa. Efele ho hlahloba ho fumana ditlhakiso tse di latelang. Ka mokgwa o latelang jwaloka, machobela a qetella ho sephethiswang, ho refilweng tharo ea molao le feo ea gear. Ho ba lefatsheng, geare tsa rona tla fumana letsatsi 6, le ho bolelwa jwalo, ho ya jwalo, le lekgetho le lenane.

·Sekhondlo sa mogaladi

1. Ho sephethisitswa kapa ho hlahloba ka geare tse 80-tse tse dinthlane tse dingwe, ithuthuthu e ne e hlahloba ho feta kgato ea motsoalle (engine) ho tsamaisa kgato ea mongwe eo e latelang jwaloka ho fumana ithuthuthu e ne e latelang dikgwalo tse pedi.

2. Ho sephethisitswa kapa ho hlahloba ka motsoalle wa dinthlane, ho ne ho latelang ho ba lefatshe le ho ba nnete, sekhutlong sa stator se ne se se khutshe pure copper le lefatsho la latelang le lenane leo la dikgwalo tse dinnye. Dikhutsong tse dinnye tse di latelang ho ba lefatshe le ho ba nnete, ho rekgweletseng dikgwalo.

·Fetsheho ye control

1. Ho sebatla relayas tse di lebetswang le mafiting a seribelo le diphofu tse tsebang, efe ho hlaboswa khanna ea boleng.

2. Ho bontsha relayas tse di latelang diketsahalo tse dingolong tsa sekere, na mafiting a seribelo a lebetsitsoe, tse pedi le tse nng le tse sa se latelang diketsahalo tse dingolong.

3. Diphuphe di hlahloba mokgwa o o lebetswang le fokotiso eo o hlokomelang. Mafiting a faele le a faele di hlahloba ka mokgwa wa kotsing ya dipole, efe ho hlahloba ka mokgwa oa ho lokisitswe le ho lokisitswa.

4. Ho sebatla diphuphe tse di resetelang lefatshe le ditlhakiso tse ngata. Mafiting di hlahloba ka mokgwa o o mongwitswang le ditlhakiso tse dingolong tsa ketone, efe ho hlahloba ditlaleho tse dingolong, di kenya amantshi le ho bolella ditaba tse nchane, le ho hlokomela lefifi la 1 million.

|

Model |

CL-150 |

CL-200 |

CL-250 |

CL-300 |

|

Lebaka la motsoali |

150MM |

200mm |

250mm |

300mm |

|

Fetola |

0.4~2.2mm |

|||

|

Coil outer senyane |

800mm |

|||

|

Thupiso ya Coil |

350kg |

400kg |

500Kg |

500Kg |

|

mokgwa |

15m/min |

|||

|

Motors |

1/2hp/4p |

1hp/4p |

1hp/4p |

1hp/4p |