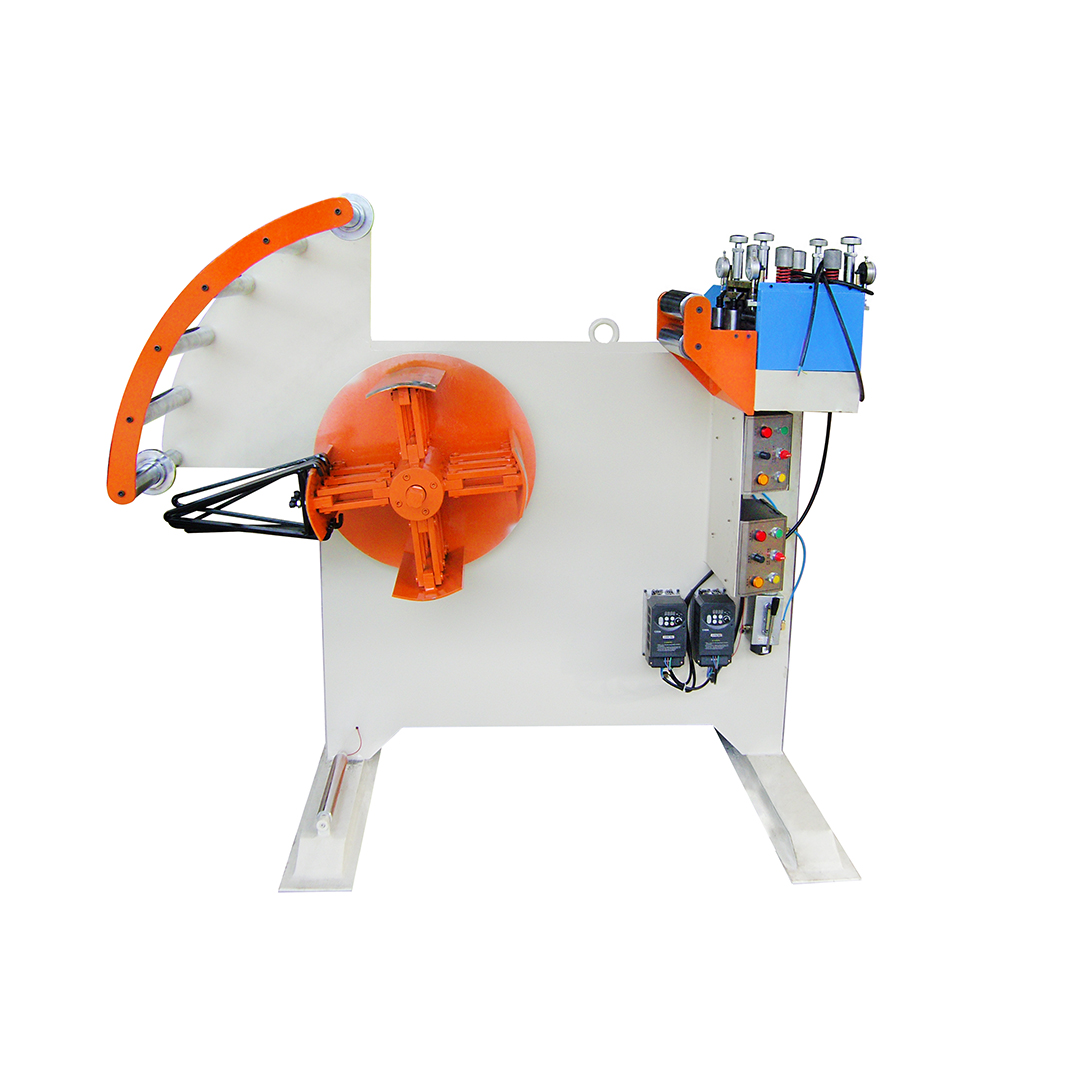

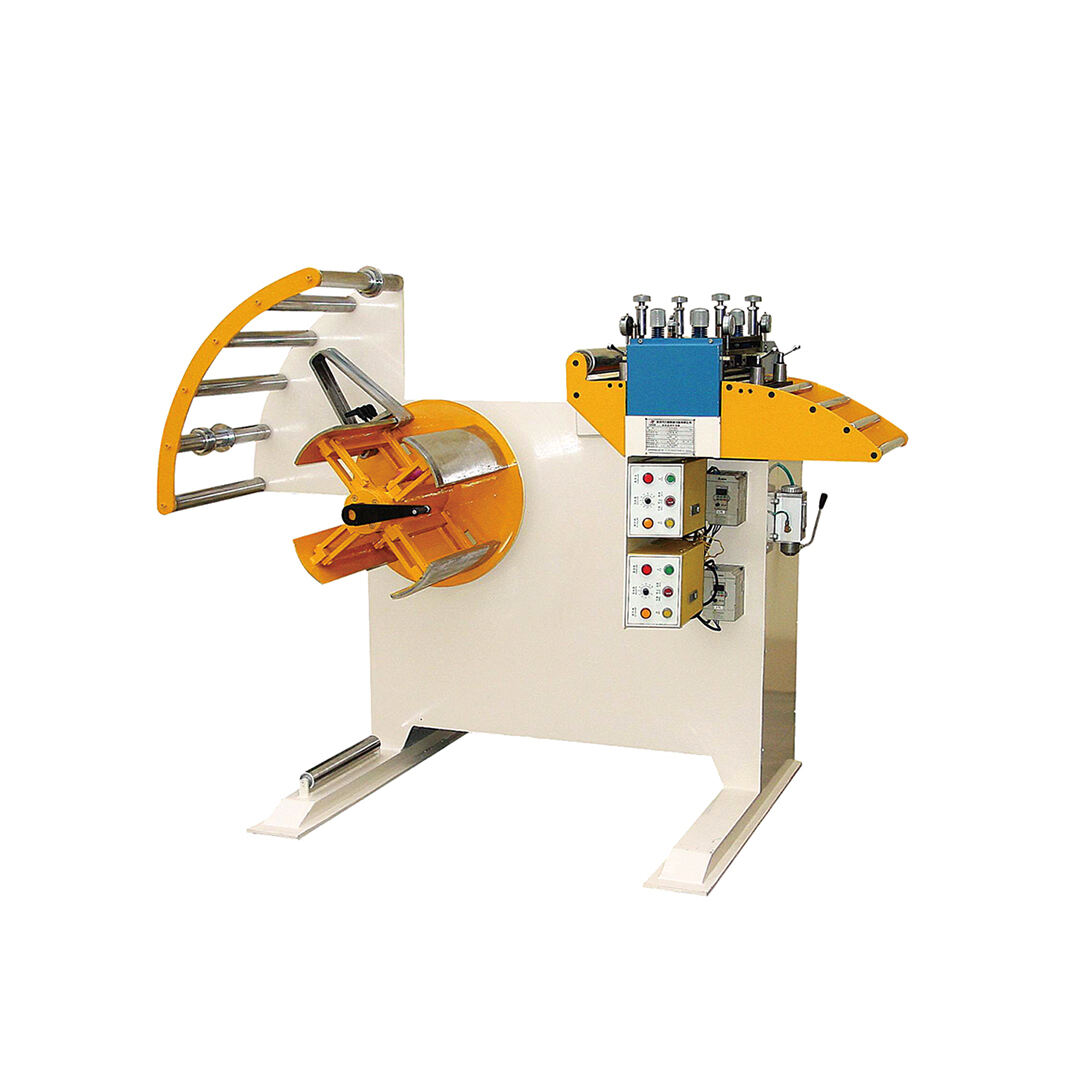

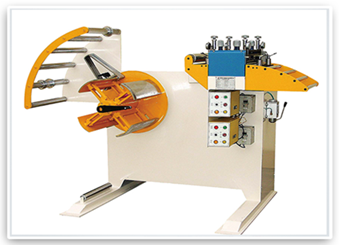

GO -B Type Straightener Cum Decoiler Bakeng sa Botenya ba Leqephe: 0.1mm~0.8mm

Share

Mochini oa ho lokisa / oa ho lokisa

Boloka sebaka

phahameng sebetsa ka ho nepahetseng

Tlhaloso ea Sehlahisoa

Straightener Cum Decoiler

Likaroloana

1. The decoiler e kopantsoe le ho otloloha, ho koahela sebaka se senyenyane, ho fokotsa khokahanyo ea phetoho ka mokhoa o otlolohileng oa lisebelisoa tse nepahetseng le ho eketsa ts'ebetso.

2. Decoiler le straightener e laoloang ka thoko ka lebokose la motlakase le ikemetseng, 'me ka mochine oa eona oa ho fetola maqhubu, ho etsa hore hohle ho tsamaee hantle, ho sireletsa mochine ka katleho, ho qoba ho sotha ho anngoeng ke matla a sa tšoaneng a ka ntle.

3. Ho otloloha ho tsamaisoa ke motsoako oa bokahohleng, ho khanna ka botlalo, ho qoba tšenyo ea thepa e bakoang ke ho potoloha ha li-rollers tse ka holimo ka katleho.

4. Rolara e otlolohileng e nang le sesupo sa ho daela, e ka fumana ntlha ea boemo kapele.

5. Ho eketsoa ha mokokotlo oa mokokotlo ho ntlafatsa ho tiea ha li-roller tse otlolohileng le ho etsa hore phello e otlolohileng e be molemo.

6. Ho eketsoa ha tsamaiso ho eketsa bophelo ba tšebeliso ea mochine.

·Hlooho e otlollang

1. Amohela moralo oa lirolara tse tšoanang, 3 holimo / 4 tlase, lirolara tse 7 ka botlalo.

2. Ho amoheloa phetoho e ntle ea lintlha tse 'nè, e leng e loketseng haholoanyane bakeng sa ho sebetsana le lihlahisoa tse phahameng tse nepahetseng. Amohela khatello e ikemetseng ea lintlha tse 'ne ho lokisa khatello ea lirolara bakeng sa ho kena le ho tsoa, e ka thibelang ho kheloha ha thepa le deformation ka nepo.

3. Rolara e tšehetsang e amohela rolara e nang le galvanizing ntle le matla, thepa ke 'mele o le mong o entsoeng, bokaholimo bo sa tsitsang le bo sa tsitsang, bo sebelisa mochine oa mochine, o potolohang o fetoha o tsitsitseng le o tšoarellang.

4. Handwheel e entsoeng ka tšepe e entsoeng ka tšepe, bokaholimo bo na le electroplated. Ke lebili la letsoho la setso ka ho fetisisa.

5. Karolo ea phetisetso e sirelelitsoe ka sekoahelo se sireletsang mahlakoreng ka bobeli, se nang le fensetere ea ho shebella bakeng sa ho shebella habonolo.

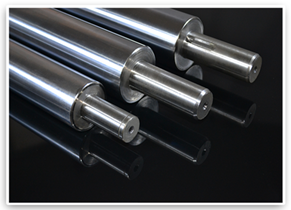

·Rolara e otlollang

1. Li-roller tse otlolohileng li entsoe ka tšepe e tiileng ea ho beleha, kalafo ea plating e teteaneng ka mor'a maqhubu a mahareng, boima ba holim'a metsi ha bo ka tlase ho HRC58, ho netefatsa ho tšoarella ha thepa.

2. Adopt GCr15 forging round steel, after preheating treatment (spheroidal annealing), ebe ho thinya, ho sila, ho phekola ka makhetlo a mahareng, ho sila ka thata le ho tsitsisa ho batang, ebe ho sila hantle, qetellong ke electroplating. Tiisetso e phahameng ea ho nepahala, ho tsepamisa maikutlo, ho qeta le ho thatafala, le ho atolosa bophelo ba tšebeliso ea lirolara.

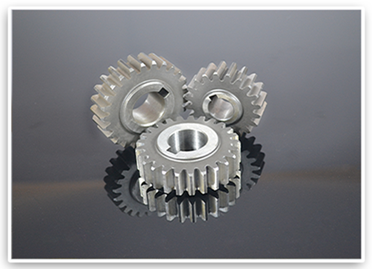

· Khanna lisebelisoa

Ts'ebetso ea li-gear e kenyelletsa lits'ebetso tse latelang: ts'ebetso e se nang letho ea lisebelisoa - mochini oa mochini oa lisebelisoa - kalafo ea mocheso - ho sila ka holim'a lisebelisoa. Likarolo tse mahoashe ke tsona tse etsang likarolo tse itseng. Ka ho tloaeleha kalafo, ntlafatsa machining ho bebofatsa ho itšeha. Ho latela metako ea moralo oa li-gear, machining a thata, ebe o qeta ho phethela, ho phethoha, ho bilika, sebopeho sa gear, ho etsa hore gear e thehoe. Ka mor'a phekolo ea mocheso ho ntlafatsa thepa ea mechine. Ho ea ka litlhoko tsa moralo oa lits'oants'o, qetellong etsa ho phethela, ho qeta benchmark, ho qeta profil ea leino. Kamora liphekolo tsohle tse kaholimo, sehlopha sa rona sa lisebelisoa se ka fihla ho sehlopha sa 6, ka khanyetso e phahameng ea ho roala, matla a phahameng, nako e telele ea ho sebelisa bophelo.

· Karolo ea foreimi

1. Thepa e amohela moralo o kopanetsoeng oa decoiler le straightener, ho ntlafatsa sekhahla sa tšebeliso ea sebaka.

2. Decoiler e amohela moralo oa beam ea cantilever, lipoleiti tsohle tsa decoiler li khaoloa ke laser plasma ka ho nepahala ho phahameng.

3. Likarolo tsohle li sebetsoa ke taolo ea linomoro le CNC, ka ho fapanyetsana hantle.

4. Sebopeho sa kakaretso se bonolo, se loketse basebeletsi ba kakaretso ba theknoloji ho bokana le ho nkela sebaka, ba ka fokotsa haholo litšenyehelo tsa tlhokomelo.

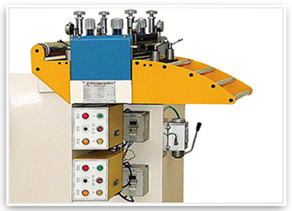

·Lebokose la taolo ea motlakase

1. Adopt silver alloy relay, coil e felletseng ea koporo, setsi sa polokeho se thibelang mollo, se tšoarellang nako e telele ebile se tšoarella.

2. Amohela ts'ireletso ea ts'ireletso ea ts'ireletso ea potoloho ea potoloho ea nako ea ho lieha, ho kopana le alloy ea silevera, ho khotsofatsa mekhahlelo e fapaneng ea ho lieha.

3. The fapoha amohela Sliding contact , ka ho intša ho itlhoekisa mosebetsi , ka tloaelo ho bula le ka tloaelo ho koaloa ho kopana amohela ka thoko bonding sebopeho, ka sebetsa le lipalo tse fapaneng, a hlomelloa le-ba khahlanong le potoloho positioning le emisa hlephileng ntseng bo eketseha gasket.

4. Adopt self-duplex flat konopo, matla a bobebe, palo ea bohlokoa e leka-lekane, mohaho oa motsoako oa mohaho oa mohaho. Khokahano e entsoe ka lintlha tse kopantsoeng tsa keto-base tse nang le conductivity e matla le hona joale e kholo, e nang le nako ea bophelo ho fihlela makhetlo a limilione tse 1.

· Karolo ea matla

1. Adopt model 80 worm gear vertical reducer, sebelisa converter ea lebelo ea gear, fokotsa palo ea koloi ho ea ho nomoro eo ue batlang, 'me u fumane mochine o nang le torque e kholoanyane.

2. Adopt vertical motor, low vibration, low lerata, stator rotor part e amohela coil e hloekileng ea koporo, bophelo ke makhetlo a 10 a coil e tloaelehileng, lipheletsong ka bobeli li na le bolo, khohlano e tlase, mocheso o tlase.

ga tlhaloso:

| Type | GO-200B | GO-300B | GO-400B | GO-500B | GO-600B |

| Max.bophara | 200mm | 300mm | 400mm | 500mm | 600mm |

| botenya | 0.1-0.8mm | ||||

| Coil.I.Dia | 450-530mm | ||||

| Coil.O.Dia | 1200mm | ||||

| Max.boima | 800kg | 1000kg | 1500kg | 1500kg | 2000kg |

| Matla a Otlolohileng | 1 / 2HP | 1HP | 2HP | 2HP | 3HP |

| UncoilPower | 1HP | 1HP | 2HP | 2HP | 3HP |

| Fetola hantle | 4 point worm gear adjsutment e ntle | ||||

| Mahala.speed | 15m / mets | ||||

| Mokhoa oa ho atolosa | Manual | ||||

| Taolo ea loop | Sensor ea ho ama | ||||