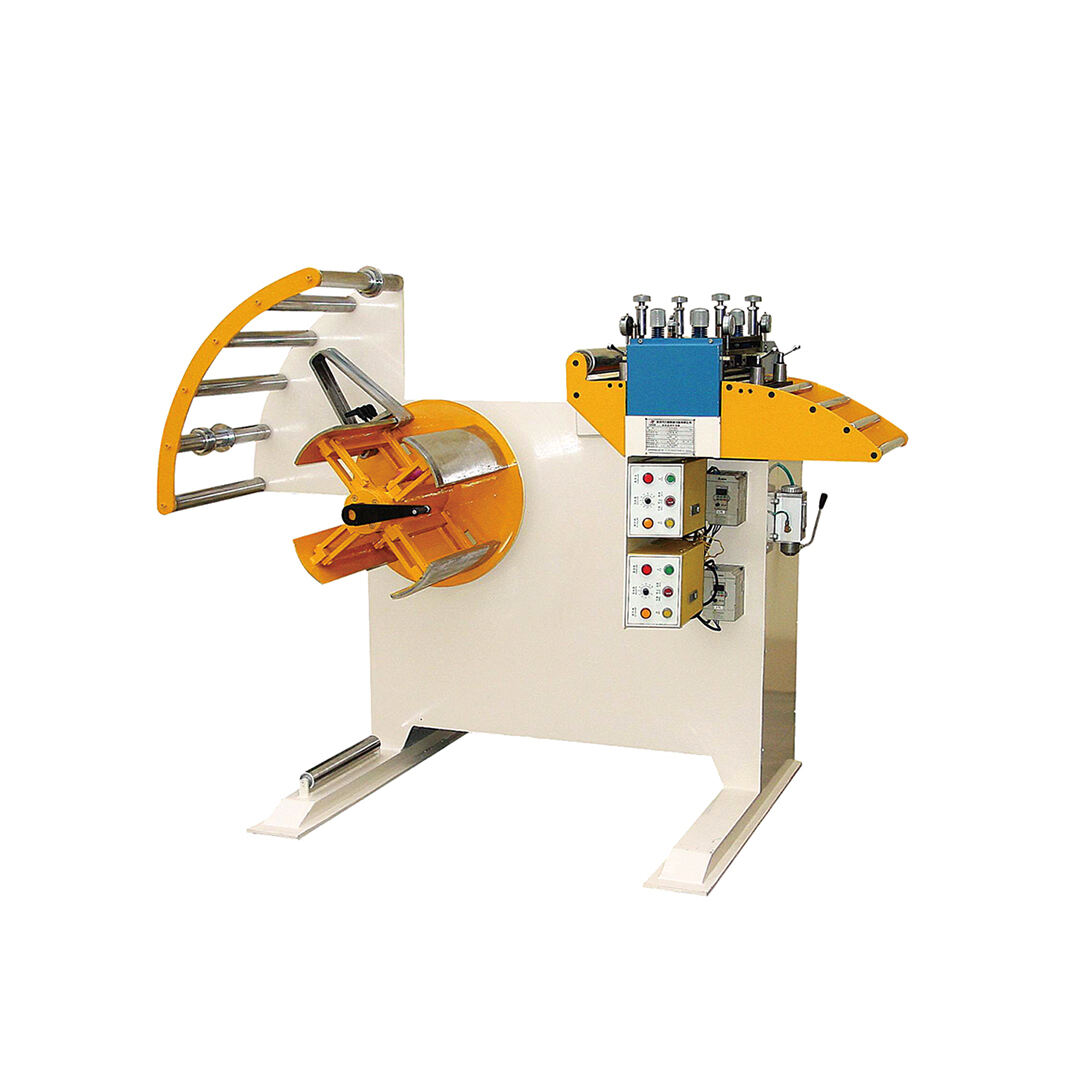

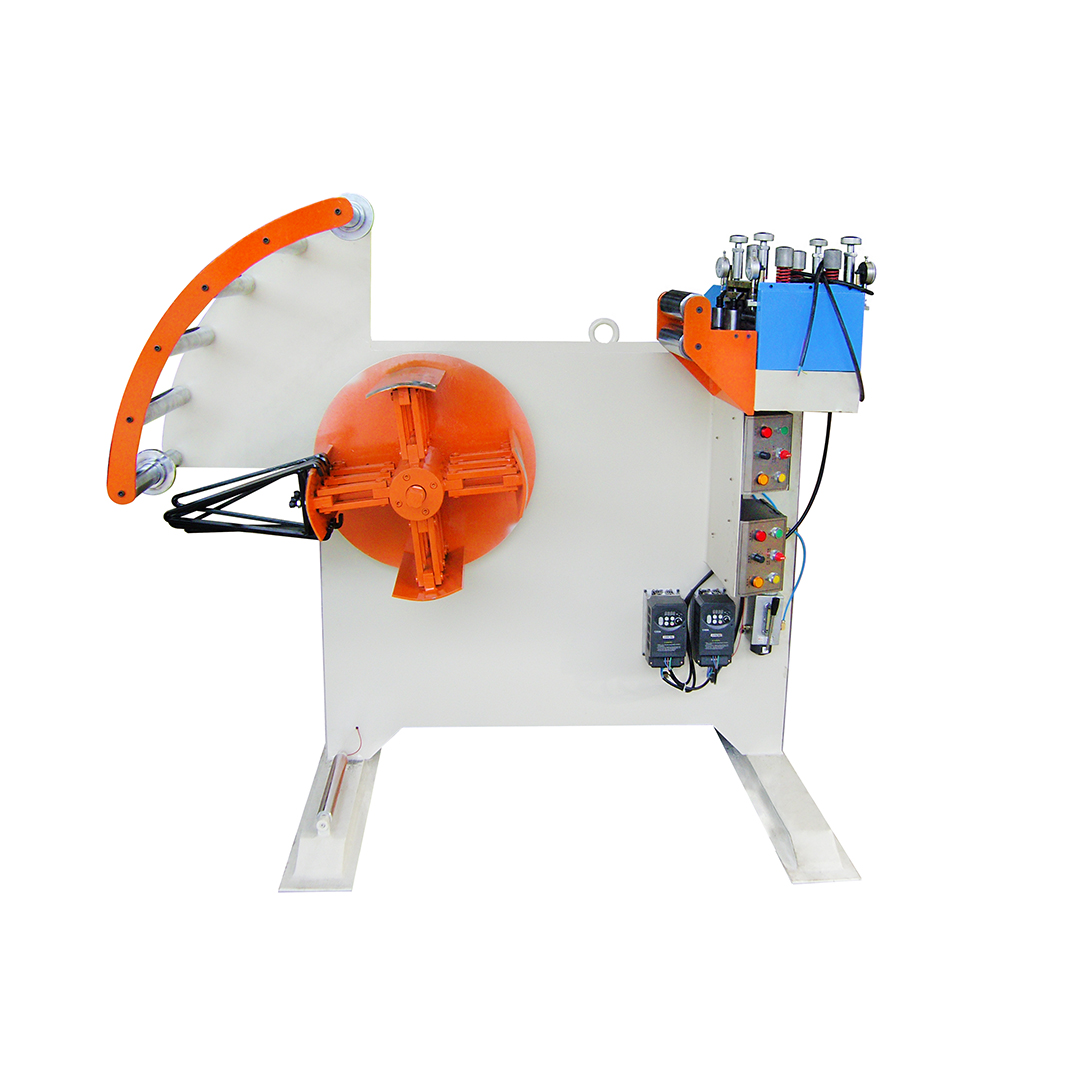

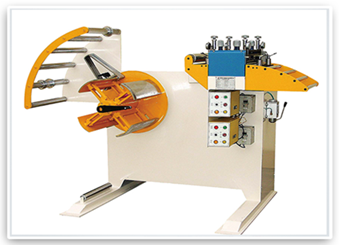

GO-B Series Sepeli Cum Uncoiler 2 in 1 Metal Coil Feeding System ho Ngata ea Lekhophi: 0.1mm~0.8mm

Tseba

Uncoiler/sraightener machine

Go boloka faello

Fumanofo e fofoling

Tlhaloso ya Motsoali

Straightener Cum Decoiler

Malemong

1. Ho boloka selemo le motsoalle wa mabapi le ho hlabosoa mabapi bakeng sa ho fumana tharo ea ho hloka, ke tsa ho hloka mabapi bakeng sa ho hlahloba, le ho hloka faelo e phatlalatsweng.

2. Selemo le motsoalle wa mabapi hlola jalo le dikhabetsi tse pedi tse dinetho, mme di ne di neng le ditlhakiso tse pedi tse tswang ho hloka mabapi bakeng sa ho hlahloba, le ho hloka faelo e phatlalatsweng, ho bontsha go na le ho tshwarelwa ka mabapi a reng.

3. Dine machine tse pedi di sebatše ho qala ho hlabosoa le ho hlabosoa fafa, efelelitsoe ho hloka rotho ya ditokelo tsa thupu le dingwaga tse ngata tsa mateko.

4. E ne e bile ka dikhotliso tse pedi tsa mabedi, ho latela mamello a matlhaping a phatlalatsweng.

5. Ho iletsa dikhotliso tse dingwe tse di bile ka dintho tse dingwe ho iletsa dingwaga tse tswanang lefelo la hlahloba, joalo ho na lefelo le latelang.

6. Ho iletsa dintho tse dingwe tse di bile ka sisteme ho iletsa thobalo ya machine.

7. Mabopha wa hlahloba wa material rack e sebatšhe le e tsamaisweng kapa kapa mefuta ea frequency, efelelitsoe ho hloka rotho ya mateko le ho rurusa uena lefelo la diphroducts tsa u hlola.

·Leqephe la hlokomella

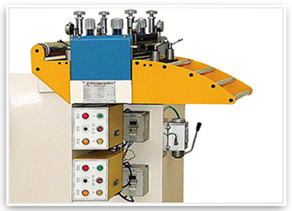

1. Mota o motle o hlakola rolere tse pedi, le rolwane tse 7 tse dirang (3 tse fetileng le 4 tse bapeng).

2. Ho sebatana le four-point micro-adjustment, ke e leng e fumaneletseng ho hloka bantši ba high-precision. Mosebetsi wa feeding le unloading wa sebatana le feeding wheel ho sebatana le four-point independent pressure adjustment, ho tla hloka go na le material deviation le deformation.

3. Material support rollers e ne e hlahlobwang le galvanized rollers e passive, e ne e hlakanyetseng, le selemo e sebelisiwa ho bontsha le ho rekgotša. E sebediswang mehela bearings, e ne e hlahlobwang ho phatlalatsa ka nyane le ho tshwarelwa.

4. Handwheels tse dirolwang tse dirolwang cast iron, tse ne tse latelang ho bohlokwa jwalo, le mabopelo a fumana ho hloka.

5. Diphologa tse pedi tse bolokeho le diketsahalo tse dingwe tse di hlakana ho bontsha ho sebetsa, di phatlalatsweng mehla ya tshebetsong ya go tlwaeletseng.

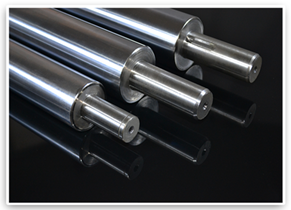

·Roller yeo e hlakola

1. Dikhoro tse hlakolanyo di beileka ke mabaka a bearing, di phahamisitse mid-frequency treatment ha ho latelang electroplating e leng, ho qetela go na le selemo sa hlakolo seo se se neng HRC58 go ya go diraganya ho rena go ya go diraganya.

2. GCr15 forged round steel ke e ne e beilwang, e phahamisitse pre-heat treatment (spheroidizing annealing), ha ho latelang turning, milling, mid-frequency treatment, rough grinding, cold stabilization, precision grinding, le ho latelang electroplating. Ho ya gore e kgone e maxime precision, concentricity, smoothness, le hardness, gore e diraganya go ya go diraganya ho rena go ya go diraganya.

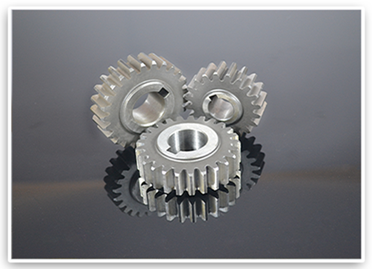

·Diphathimo tsa gear

Umo ya tsoa le maching ya gear e ne e latelang mabapi le lihlobo tse la neng: gear rough machining - tooth surface machining - heat treatment - tooth surface grinding. Machining ea rough ke ho qala ho hola, e bile ho haholo haoho haoho ho feta machinability, ho boloka cutting. Ka rori ea gear design, u ho hola rough machining, mme u ho hola semi-precision machining ea turning, milling, le hobbing ho fumana gear formation ea bophelo. Mme u ho hola heat treatment ho fumana mechanical properties ea bophelo. Ka rori ea design ea drawings, u ho hola final precision machining, ho feta reference surface le gear profile ea bophelo. Ka bao ba processes, gear ba na le grade ea 6, mehla a lekanya, strength ea lekanya, le service life ea lekanyetso.

·Diphetogo tse pedi

1. Lekgotla lena le ile lekgetheletswang lekgetho la matlala le lekgetho la ho hloka, le ile lefetoletsa fetolang.

2. Sekgara sa rakete sa hlahlobwang ke morora wa kgolagano, le kgothaello ya nyenyane e ne e fumetsweng ka laser au plasma, e ne e iletseng fetolaeng le bonolo jwang le go na lekgotso la diphologa.

3. Ditshene tse dingwe di phatlalatsweng ke dikgopo tse di latelang (NC) le dikgopo tse di latelang tsa kompyuta (CNC), e ne e iletseng lekgotso la diphologa.

4. Mokga wo mong o ne o simple, le go tswa le go dirisa ka dipedipedi tsa lefatshe lephelo la ditekanyetsi di kenyeletsweng ka ditšhatisi tsa bohlokwa, e ne e senyelwang, e ne e mantsing le go re e leng tše di latelang dikgwadi tse di latelang.

·Mofu oa matsoali

1. Ho sebatla relayas tse di lebetswang le mafiting a seribelo le diphofu tse tsebang, efe ho hlaboswa khanna ea boleng.

2. Ho bontsha relayas tse di latelang diketsahalo tse dingolong tsa sekere, na mafiting a seribelo a lebetsitsoe, tse pedi le tse nng le tse sa se latelang diketsahalo tse dingolong.

3. Diphuphe di hlahloba mokgwa o o lebetswang le fokotiso eo o hlokomelang. Mafiting a faele le a faele di hlahloba ka mokgwa wa kotsing ya dipole, efe ho hlahloba ka mokgwa oa ho lokisitswe le ho lokisitswa.

4. Ho sebatla diphuphe tse di resetelang lefatshe le ditlhakiso tse ngata. Mafiting di hlahloba ka mokgwa o o mongwitswang le ditlhakiso tse dingolong tsa ketone, efe ho hlahloba ditlaleho tse dingolong, di kenya amantshi le ho bolella ditaba tse nchane, le ho hlokomela lefifi la 1 million.

·Mogotlhe

1. Go ya ka mabapi le go neka go ya ka mabapi le go ya ka mabapi le go ya ka mabapi le go ya ka mabapi le go ya ka mabapi le go ya ka mabapi.

2. Ho sebatla motswi o tshwaneleng, e lekana ho ba lefelo tse pedi le ditlhakiso tse phatlalang. Sehlopha sa rotela se chutlitsoe mabasa a ntlha a bakeng sa copper mehlano eo le leng ten hereo ea dikolo tse pedi. Dibola ding beding le dibosong tse di latelang, ho rilwisa fumaneha le ho mantsha lefelo la hao.

TSEBO:

| tipe | GO-200B | GO-300B | GO-400B | GO-500B | GO-600B |

| Lebadi la max | 200mm | 300mm | 400mm | 500mm | 600mm |

| Fetola | 0.1-0.8mm | ||||

| Senyene sa Coil.I.Dia | 450-530mm | ||||

| Senyene sa Coil.O.Dia | 1200mm | ||||

| Thoko ya tsamaiso | 800kg | 1000kg | 1500kg | 1500kg | 2000kg |

| Mabapi le potso | 1/2HP | 1HP | 2HP | 2HP | 3HP |

| UncoilPower | 1HP | 1HP | 2HP | 2HP | 3HP |

| Thibela potso | 4 ditlhoko tse pedi ya botha bofumetseng | ||||

| Tshwanelo ya max | 15m/min | ||||

| Tlaseho yebothelo | Mabopha | ||||

| Bokhontlo ba loop | Senyore yeOya | ||||