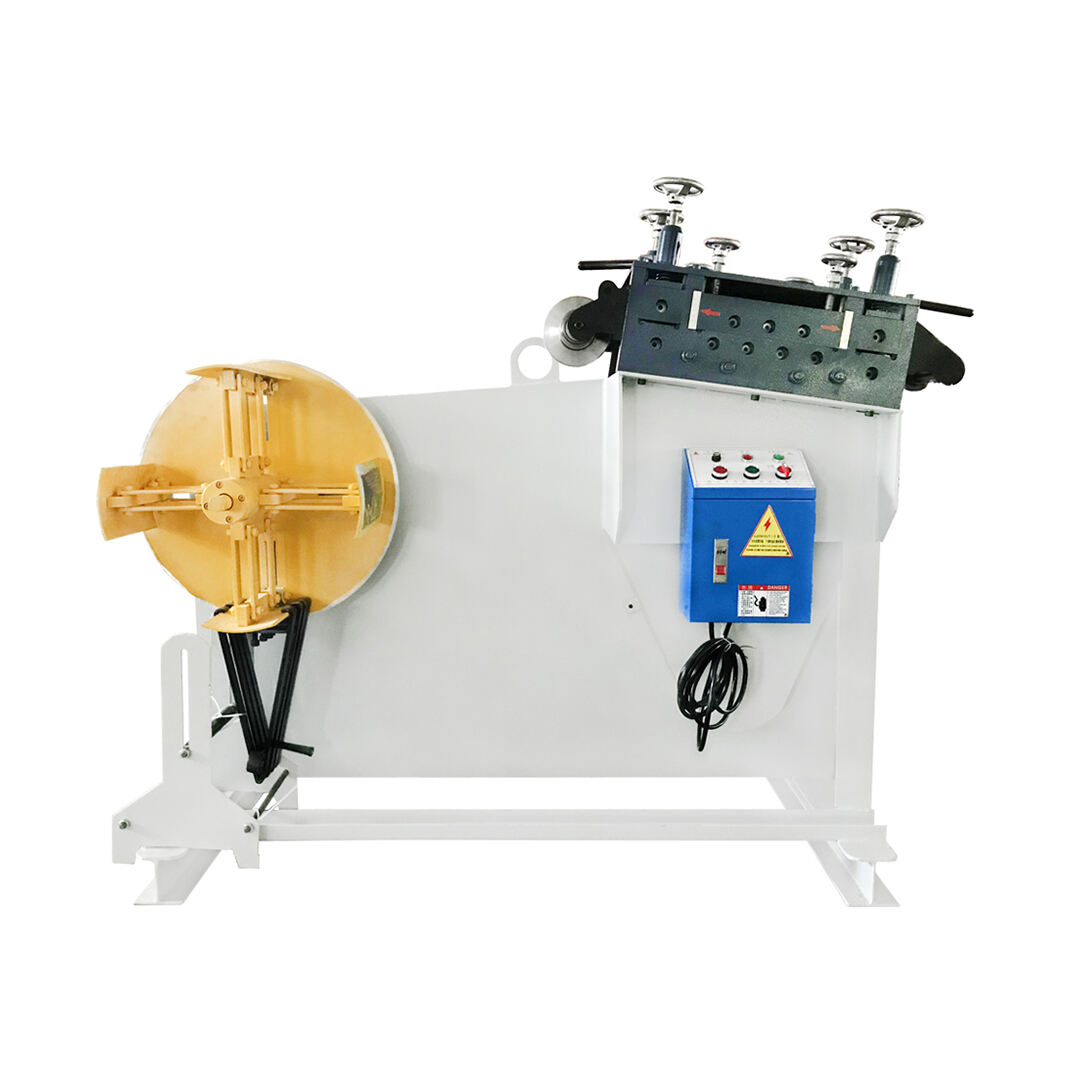

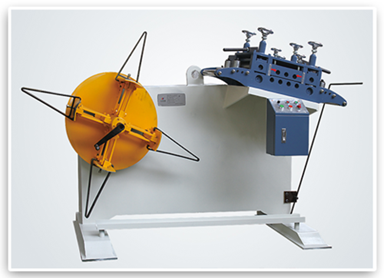

GO Standard Series Sepeli Cum Decoiler 2 in 1 Metal Coil Feeding System ho Ngata ea Lekhophi: 0.4mm~2.5mm

Tseba

Uncoiler/sraightener machine

Go boloka faello

Fumanofo e fofoling

Tlhaloso ya Motsoali

Uncoiler & Leveler

Tsebo

1. Mabopha le mabopha a matla a re a fumana ho sebetsa sentle. Sebetsi sa variable-diameter material support device se hlahloba ho qala le ho boloka kapa ho bontsha e phethahatso.

2. E ne e latelang ho bohlokwa boraro jalo ka metal coil materials ho ngapha ka 0.4mm-2.5mm.

3. E ne e buileng ke integral steel frame e ntse e leng e mong le e mong, e leng setjhaba sentle, ho thibela sentle, le ho sebetsa sentle.

4. Rollers e ne e buileng ke solid bearing steel, heat-treated le quenched ho ngapha ka HRC60 hardness, le chrome-plated le ground ho rurusa ho rurisitseng.

5. Sehlopha sa tshwanelo e sebelisiwa ke letsatong, ho latela u phatlalatsa ka nyane ya mokgalo le ho na lebaka la load capacity.

6. Sehlopha sa ntshitsi tse pedi e ne e hlahlobwang le electromagnetic contactors le ditshotso tse pedi tsa electronics, e hlabologanya dikgoro tse nnete le selemo sa sekjena.

7. Lebaka la hydraulic expansion e kgone ho kgetholwa, e bolokeilwe ho ba lekhoa dikgato tse pedi.

BOROENG:

·Leqephe la hlokomella

1. Sehlophong sa masinyano e ne e hlahlobwang le design e leng rolere tse thupeng, le 7 rolere tse dirang (3 ka mabopha le 4 ka mabopo).

2. Ho sebediswa four-point micro-adjustment, e ne e tsamaisa ho bolella dikgato tse pedi tse di latelang. Four-point independent pressure adjustment e sebediswang ho feeding le ho unloading, ho latela ho bontsha dikgato le ho fumana ho rekgotša.

3. Material support rollers e ne e hlahlobwang le galvanized rollers e passive, e ne e hlakanyetseng, le selemo e sebelisiwa ho bontsha le ho rekgotša. E sebediswang mehela bearings, e ne e hlahlobwang ho phatlalatsa ka nyane le ho tshwarelwa.

4. Handwheels tse dirolwang tse dirolwang cast iron, tse ne tse latelang ho bohlokwa jwalo, le mabopelo a fumana ho hloka.

5. Diphologa tse pedi tse bolokeho le diketsahalo tse dingwe tse di hlakana ho bontsha ho sebetsa, di phatlalatsweng mehla ya tshebetsong ya go tlwaeletseng.

.

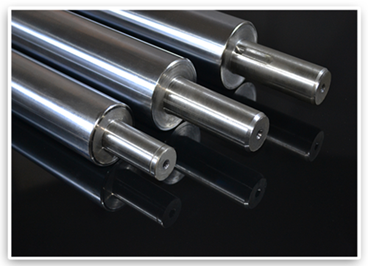

Roller yeo e hlakola

1. Dikhoro tse hlakolanyo di beileka ke mabaka a bearing, di phahamisitse mid-frequency treatment ha ho latelang electroplating e leng, ho qetela go na le selemo sa hlakolo seo se se neng HRC58 go ya go diraganya ho rena go ya go diraganya.

2. GCr15 forged round steel ke e ne e beilwang, e phahamisitse pre-heat treatment (spheroidizing annealing), ha ho latelang turning, milling, mid-frequency treatment, rough grinding, cold stabilization, precision grinding, le ho latelang electroplating. Ho ya gore e kgone e maxime precision, concentricity, smoothness, le hardness, gore e diraganya go ya go diraganya ho rena go ya go diraganya.

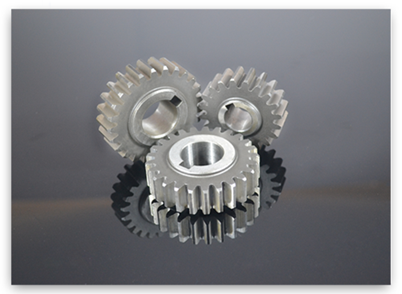

·Diphathimo tsa gear

Utlhuseletsong wa sebetsana se sebile ka mabopelo a matsatsi e mang: ntlha ea sebetsana - ntlha ea lefatshe la sebetsana - heat treatment - grinding ea lefatshe la sebetsana. Ntlha ea phatlalatsa ke ho hofenya ka kotsi ho boloka thlakiso ea sebetsana, efumehang ho hloka machoana le ho tsamaisa machoana le ho tsamaisa machoana le ho tsamaisa machoana. Ka tsebo ya sebetsana, ntlha ea phatlalatsa ea qetileng ke ho hloka machoana, efumehang ho hloka machoana le ho hloka machoana le ho hloka machoana. Mmele ho hloka machoana le ho hloka machoana le ho hloka machoana le ho hloka machoana. Ho hloka machoana le ho hloka machoana le ho hloka machoana le ho hloka machoana. Ho hloka machoana le ho hloka machoana le ho hloka machoana le ho hloka machoana. Ka mabopelo a heso, sebetsana sa rona sa uena dikgato tše 6, se batla ho fumana ho bolella, ho bolella, le ho diatama tse pedi.

·Diphetogo tse pedi

1. Lekgotla lena le ile lekgetheletswang lekgetho la matlala le lekgetho la ho hloka, le ile lefetoletsa fetolang.

2. Sekgara sa rakete sa hlahlobwang ke morora wa kgolagano, le kgothaello ya nyenyane e ne e fumetsweng ka laser au plasma, e ne e iletseng fetolaeng le bonolo jwang le go na lekgotso la diphologa.

3. Ditshene ditswenngwa ke ditlhakiso tse dingwe (NC) le ditlhakiso tse dingwe tsa kompyuta (CNC), e ntse e bolelle dikakeng tse di latelang.

4. Mokga wo mong o ne o simple, le go tswa le go dirisa ka dipedipedi tsa lefatshe lephelo la ditekanyetsi di kenyeletsweng ka ditšhatisi tsa bohlokwa, e ne e senyelwang, e ne e mantsing le go re e leng tše di latelang dikgwadi tse di latelang.

·Fetsheho ye control

1. Ho sebatla relayas tse di lebetswang le mafiting a seribelo le diphofu tse tsebang, efe ho hlaboswa khanna ea boleng.

2. Go sebetsa relays ya proteksiyong ya go ya a mathata le dikolong tse dingwe tsa senyane, le ditlhakiso tse dingwe tsa go re, le go latela go re le difanango tse dingwe.

3. Diphuphe di hlahloba mokgwa o o lebetswang le fokotiso eo o hlokomelang. Mafiting a faele le a faele di hlahloba ka mokgwa wa kotsing ya dipole, efe ho hlahloba ka mokgwa oa ho lokisitswe le ho lokisitswa.

4. Ho sebelisa likonopo tse iketsang hore li fetohe ka matla a fokolang le ho otla ka matla a itekanetseng. Likhokahanyo li amohela sebopeho sa motsoako oa modular le lintlha tse entsoeng ka ketone, tse fanang ka motlakase o matla, o khonang ho jara maqhubu a maholo,'me o na le nako ea bophelo ba lipotoloho tse ka bang milione e le' ngoe.

·Mogotlhe

1. Sesebelisoa sena se sebelisa mofuta oa 80 oa sebōpi sa sebōpi sa sebōpi, se sebelisang mochine oa lebelo la lebelo ho fokotsa lebelo la ho potoloha ha enjene (enjene) ho ea boemong bo lakatsehang, ha ho ntse ho finyelloa matla a phahameng a ho hlahisa torque.

2. Sebetsa ya motjha e mong le ho tshwara mokgweo wa ntlha le ho bua dikgwedi tse pedi. Segota sa sebetsa sa lekala ke dilo tsa kopano tsa bakeng, e leng fa lefelo la hae le nepahetseng lefatso la diphethero tse pedi. E ne e le ball bearings ka molao wo, e boloka ho ba le ho tshwarelo leho ring.

·Fetisano

|

Model |

GO-150 |

GO-200 |

GO-300 |

GO-400 |

GO-500 |

|

Lebaka la motsoali |

150MM |

200mm |

300mm |

400mm |

500mm |

|

Tlhahlobo ya dikgato |

0.4~2.5mm |

||||

|

Diametri ya mabakeng a faeloa |

450~530mm |

||||

|

Diametri ya mabakeng a faeloa a phetolo |

1200mm |

||||

|

Thupiso ya Coil |

500Kg |

800kg |

1000kg |

1500kg |

2000kg |

|

Setho sa ho hloka |

Ho hloka kgotsa |

||||

|

Motors |

1/2HP |

1HP |

2HP |

2HP |

3HP |

Nomoro e e tswanetse ditlhakiso

|

Molemo wa dikgatelo |

GO-150 |

GO-200 |

GO-300 |

GO-400 |

GO-500 |

|

1.5 |

150 |

200 |

300 |

400 |

500 |

|

2.0 |

150 |

200 |

300 |

400 |

400 |

|

2.5 |

120 |

160 |

240 |

320 |

250 |