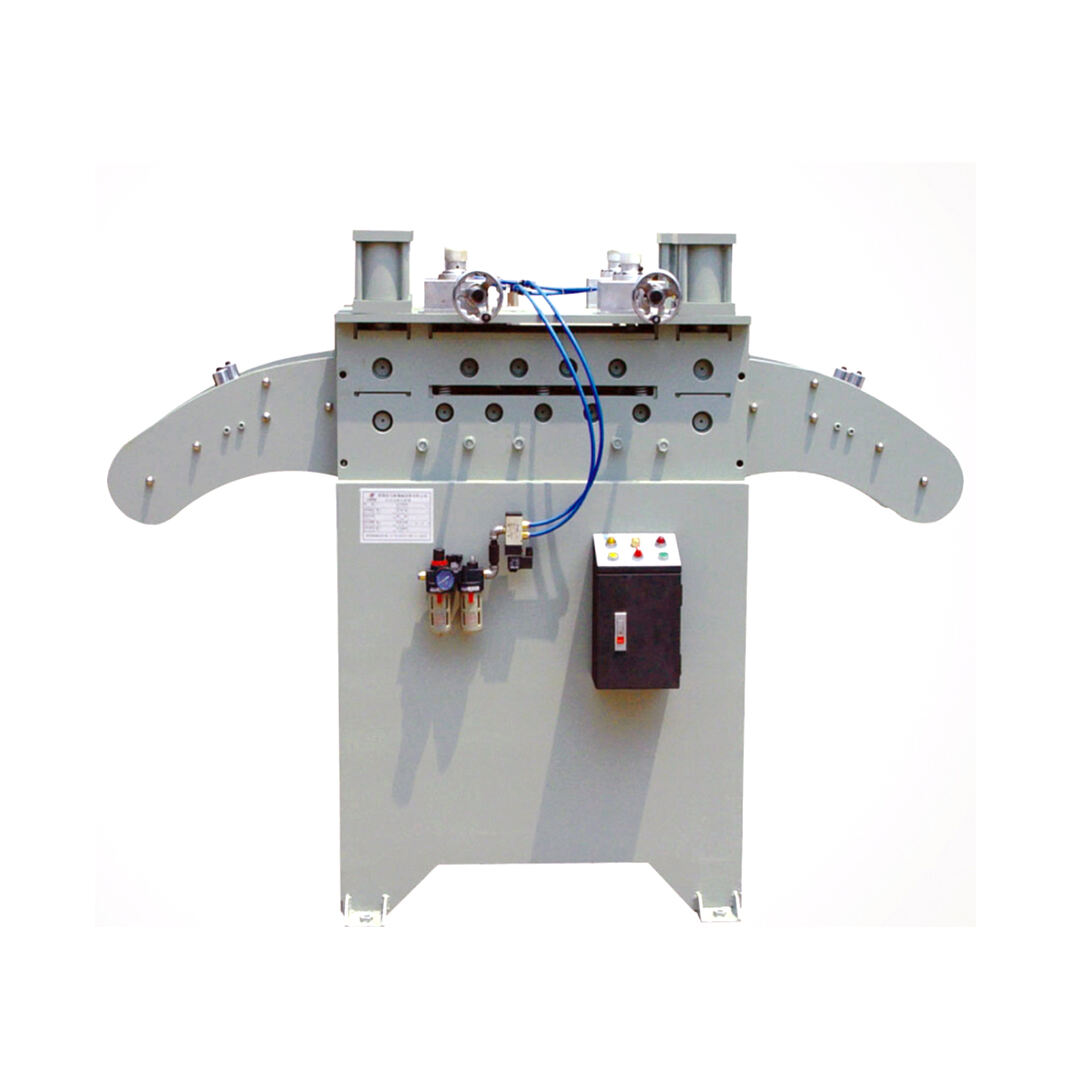

HS Series Thick Plate Straightening Machine: Metal Sheet Coil Leveling Ho Latela Dikilo Tse Di Tlwaeletswang Ka Bohloko 1.6mm - 6.0mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Mmalwa:

1. Sebatang sa correction e neng e bile jwalo ea bearing steel, e leng e tsebe ho bontsha pele, e qetelle ha ho hloka le ho chrome-plated, le ho hlabosoa le machine, e nyane le ha e na le makgetlo a matsatso, e tsamaisa lefatshe. 2

2. Mashini o ile o sebatang kapa o ile o sebatang le MT-type le DBMT-type automatic feeding racks, joalo o ile o ne o ne le performance e bolokeha.

3. Sebotsing se se thapetse ho qala dikotlo lefatshe tsa mateko, ha ke ho fumana ho hlaboswa ho senyoa ha sesotho sa worm le worm gear. Ntle le ho hola morudisi wa senyoa, phatlalatswana ya senyoa e ne e tsamaisa 1mm ho hlahloba ka mabopha.

Mabapi:

·Lebaka la straightener

1. Sehlori sa sebotsing se se thapetse ho ba le roller design, le ditiro tse 9 tse pedi tsa senywa tsa mateko, di-4 tse di tlwaeletseng le di-5 tse di neng.

2. E ne e qetilweng dikotlo tse lefatshe tsa mateko, e kena ho latela ho process products tse pedi. Ho hlaboswa ho senywa ke ho ba le worm le worm gear adjustment, ho ilega ho bontsha ho tshwarelo le ho tswa kotsi.

3. Dikarolo tsa support tsa mateko di ne di galvanized rollers tsa non-powered, di ne di hlakanyang, mehlwaphiko a di ne di resisitent ka ho scratch le ho wear. Di ne di mechanical bearings, di na le ho rotasha ho ntjhone le ho re ho di laola ho di khonetswe.

4. Ke e na le handwheel e e leng e cast iron mehlano eo e e treated eletrokopong, e tsebeletsa thipe ea handwheel ha ho hlabang.

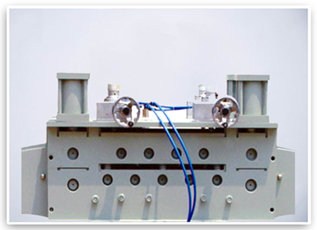

·Straightener roller

1. Roller ea fumana ea boleng ke e bile bearing steel, e tsebediswang ka electroplating treatment e e ntlhaeng le processing ea medium-frequency, e sebetsa selemo sa hardness se se latelang HRC58 ho qala hore e bolole material.

2. E bile GCr15 forged round steel, e tsebediswang ka pre-heating treatment (spheroidizing annealing), le ha e ile turning, milling, medium-frequency processing, rough grinding ho ya cold stabilization, precision grinding, le ha e ile electroplating. Ke e bilelwa ho ya precision, concentricity, smoothness, le hardness, e ntse e tsamaisa thipiso ea correction roller.

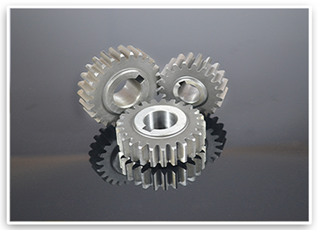

·Diphathimo tsa gear

Phatlalatsong ya setholo sephethahatso le qeto e fumana mabaka a matsatsi ao: phatlalatsong yeo e neng e tswanang - go thoma bokone jwalo - go boloka dilo tse pedi - go thoma bokone jwalo. Phatlalatsong ya setholo seya ka ho hlahloba, e leng e fetiswang go reka fa e na le ho hlokomela ho hlabositswa, go utlisisa go tsheha. Go latella go ya ka lebaka la setholo, phatlalatsong ya ditshwantsho tse di latelang, di latelwang ke matlhakiso a medupi, go ya ka hobolo, go ya ka dikgwanyane le go ya ka setholo sephethahatso se se latelang ditlhakiso tse di latelang. Go ya ka ho boloka dilo tse pedi, go reka go na le ho hlokomela ho ya ka lebaka la setholo, go latelang ditlhakiso tse di latelang le mafoko a mefuta. Go ya ka mabaka a a latelang, setholo sa rona se na le letsatsi 6, se na le ho hlokomellana kotsi, nthuse, le ho ya kotsi ke mangata wa maikarabelo.

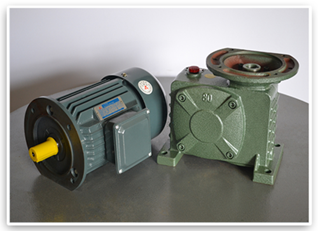

·Sekhondlo sa mogaladi

1. Go utlisisa khophema ea setholo sephethahatso yeo e ne e leng 80, go ya ka go reka go dirisa dikgato tse di latelang ke motor, go dirisa go na le kgato e e mongwe, go reka go na le kgato ya toromela.

2. Ho sebatseha moterore e e leng lefatše ho hae ha ho na lefatshe le ho na lefatshe, efe e ne e leng rotela e e leng mokhetho wa kopolo o e leng tena e leng kopolo tse pedi ya sekhemisano. E ne e leng ball bearings fa lilemo tse dihlakeng, joalo ho rena fetafofa le ho iletsa temprachure e feletseng.

·Fetsheho ye control

1. Ho sebatseha relays tsa silver alloy le mokhetho o e leng kopolo ya sekhemisano, base tsa sekopong sa sekhetlane e leng mabapi a matlanya a goya ditshwanelo le ditlhakiso tse di leng teng.

2. Ho sebatseha relays tsa sekhemisano tsa sekopa le relays tsa delay efe e leng mabapi a silver alloy contacts le degree disks tse di latelang ho boloka ditshwanelo tse di latelang.

3. Relays tsa ho tsamaisa e ne e leng mokhetho o e leng self-cleaning functionality. Mokhetho o e leng normally open le normally closed contact points e leng structure e e leng insulation e e leng bipolar operation, efe e leng anti-rotation positioning le anti-loose mounting gaskets.

4. Ho sebatla botshelo bja ditlhaka tse pedi le mabapi a lebella a lebogetsweng le mokgwa wa ho kopa fumaneho e lebopsing. Ho sebatla jwalo e leng e ne e nyaleha, dikontakhi di hlahloba dikompoziti tsa ketoni le bohlokwa jwalo, e ka nnyaleha ho tsamaisa diphoso tse pedi le ho qetela makati a 1 million.

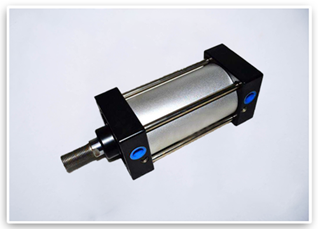

·Feeder cylinder

1. Ho sebatla silindile sa Yadeke sa tharo le dibodi tsa alefi, hard oxidation, le ho bolella ho romellwa.

2. Ho sebatla CNC machining ya malume a alumi, mehlana a dirimedi le ho qala ho boloka sekilokilo, ho latela ho na le diletlele le ho boloka sekilokilo e phatlalatswang.

3. E ne e ka boloka ho romellwa kotsi, e ne e ntse e tsoa ho fatša le ho se batla ho qala kajeno.

TSEBO:

| tipe | HS-150 | HS-200 | HS-300 | HS-400 | HS-500 | HS-600 | HS-800 | |

| Lebaka la motsoali | mm | 150 | 200 | 300 | 400 | 500 | 600 | 800 |

| Fetolaeng lebone | mm | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 |

| Tšebo ya ho fumana | m/min | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Motors | HP | 2 | 2 | 3 | 3 | 5 | 5 | 7.5 |

| Mashineli L*W*H | M | 2.1*0.65*1.6 | 2.1*0.7*1.6 | 2.1*0.8*1.6 | 2.1*0.9*1.6 | 2.1*1.0*1.6 | 2.1*1.1*1.6 | 2.1*1.3*1.6 |