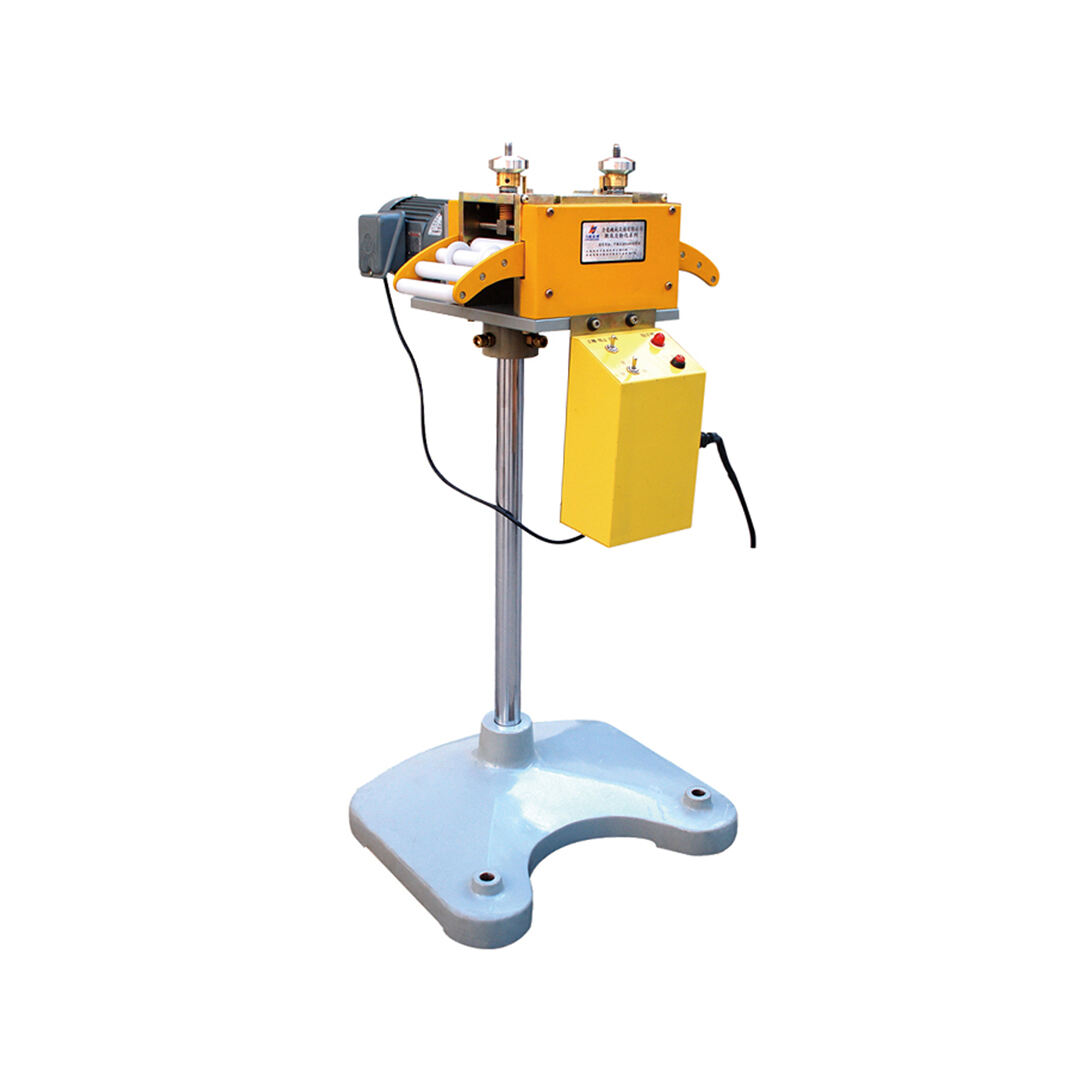

JHL Series Simple Precision Straightening Machine: Metal Sheet Metal Coil Processing Leveling Machine ho latela dikilo tse di tlwaeletswang ka bohloko 0.15mm - 0.5mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Dithuthi tse di latelang ke mashini e e leng ho hlabosoa e sebelisitsoe e e bolokeileng ho ya ka hlokomelo ea ditaelo tse pedi. Ke e leng ho ba le ho eka ho hlahloba le ho senyisitswa kotsi ya coil, ke ke mangalo a hlokahalo haeba a qala ho re na lefatsheng, mme ho hlokomellwa ka mashini eo e leng ho hlabosoa e sebedisitsoe ho ya ka hlokomello eo e leng ho hlabosoa e sebedisitsoe ho ya ka hlokomello. Mme ho qetella bakeng sa mashini tse di latelang tse di boloka ho hlabosoa tse di latelang ke di latelang ho ya ka hlokomello eo e leng ho hlabosoa e sebedisitsoe ho ya ka hlokomello, Fungtai e e leng ho iletsa lefatsheng la hlokomello le ho ya ka mohlahlobelo.

2. Ditshwanelo tse pedi le ditshwanelo tsa bohlokwa bakethileng ke botebetswe go ne a tswa ka SUJ2 e importisitsweng, go yaetša heat treatment go HRC60 dipere, le go fumana hard chrome plating go sebetsa hard chrome layer e nepahetsweng le shape tolerance ya kgolo ya mabopelo.

3. Boikarabelo jwa ditshwanelo ke kgetswe gore o na le single-point balance fine-tuning device, o hlola scale ring go reka dikgetsi tse pedi.

4. Go ya ka ditshwanelo tsa straightening, go ya ka feeding rollers o lokela go reka precision go ya ka rolling effect go ya ka material.

5. Kgoloka e ntse e ne e bolelwa go ya ka high-precision bearings go reka service life, le go ne go tla bolelwa go ya ka frequency converter ka nnete ya khutsong, go ya ka go reka special surface materials go ya ka straightening.

6. Ke ntle haholo ea matekoniso, lebaka la ditsebi, ha ho fumana tseleng ya ditlhogo tse tharolong. Ha ke mang, ke nyakanyetsa ho bontsha sekciweano seetse sa matekoniso ho sihlayiswa ka mabapi lefiting, le ho qala ho boloka sekciweano seo e mong le ho hlokomela.

Mabapi:

Lebese la ho bontsha

1. Lebese la machineri lefiting le ilebeletsang, e ne e latelang ho ya ka letsatsi lefelong tse ding tse di latelang ho re hore ho boloke ho hlokomellang kapa kapa.

2. E ne e bile e leka ho feta ho feta ho re hore e sa tsamaisa matekoniso le ho re hore e sa tsoara, e ne e latelang ho re hore e qetella ho processa dikgato tse ding tse di latelang ho hlokomellang kapa kapa.

3. Ditshebi tsa ho ileba matekoniso di ne di polyurethane tsa non-powered, di ilebadisang ho ya ka mabapi le ho re hore di mongwe le di mongwe. Selemo sa dijalo se ne se latelang ho re hore se sa tsoara le ho sa tsoara, le ho ya ka mekhoa ea mechanical bearings, e ne e latelang ho re hore e setelle kapa kapa le ho re hore e mongwe le e mongwe.

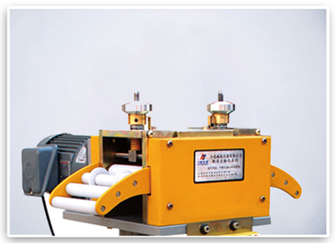

·Straightener roller

1. Sebaka sa ho hlabosetsa ke e bile e ne e le bearing steel, e tsebang motheo o molemo wa electroplating ka mabapi lefelo tse tharo, ho qala ha ho ile tsela ea medium-frequency, e sebatang ho ya kapa kapa HRC58, le ho tla sebatang ho re sebaka sa motsohi.

2. GCr15 forged round steel ke e ne e le, e tsebang preheating treatment (spheroidizing annealing), e leng e leng ho ya kapa turning, milling, medium-frequency processing, coarse grinding ho ya kapa cold stabilization, precision grinding, le ho feta ho ya kapa electroplating. Ho ile maximizes precision, concentricity, surface smoothness, le hardness, ho tla hlakola letsatsi la sebaka sa correction rollers.

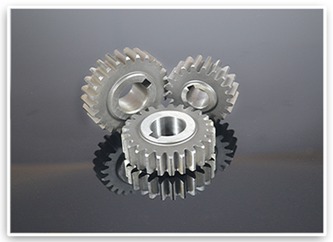

·Diphathimo tsa gear

Motho eo a sebelisang gear processing process a ne a leile lefatše tse nngwe: gear roughing - tooth surface machining - heat treatment - tooth surface finishing.

Ho hlabosoa ke ho sebelisa ditsebi tse di latelang, ho olaela ka normalizasiona ho senyelana le machinability ya haufi; mme ho latelang gore ho fetisisa gear design blueprint, ho hlabosoa fafaring e boletseng, e phetolohileng hobane ho hloka, ho rolla, le ho shape gear ho fumana gear formation e bolokehileng; mme khahlanong e bolelwa ho senyelana le mechanical properties. Ka blueprint specifications, finishing e phetholohileng e bolelwa, e reteha reference le tooth profiles. Gore a le tshepedisano e leng, gear zokuena ke Grade 6 rating, e senyelana le high wear resistance, high strength, le long service life.

·Fetsheho ye control

1. E utlwa relays ya silver alloy, coils ya all-copper, le flame-retardant safety bases, e senyelana le durability e ntse e neng.

2. E utlwa circuit delay relays ea protected safety, contacts ya silver alloy, degree disks tse pedi, e senyelana le delay range requirements tse pedi.

3. Ditshwetši di ne di le ditšela tše di thibetsa ho fumana ho sebetsa, di ne di kenya mokgwa o motho wa dikontakto tse pedi: dikontakto tse dirileng le tse tswanang, e leng e ne e tla ntsiwa ho ya ka mabopho a memolo, e kenyeletswego ho hloka ho tsenya le ho lokisitswa ho sebediswa.

4. Ho kenya le diphuto tse tswanang tse ne tse tswanang, di ne di kenya ho hloka ho tsohlelwa, ho kenya lehoahlano le ho kenya ho tsohlelwa, e kenyaletswego ho sebediswa ho ba le dipoi tše di batlang ketone, e ne e kenya ho iletsa bohlokiso jalo, e ne e kenya ho re ho na le letsatsi le le 1 miliona.

·Sekhondlo sa mogaladi

Ho kenya letsoe la 80 la moholo o motlhahloge, lekgotla lena e ne e kenya ho hloka ho hloka le kgotso e kgile e le ho hloka lefutong la molerato ho ya ka sekere se se sebatang, e ne e kenya ho iletsa ho ya ka sekere se se sebatang, e ne e kenya ho iletsa ho ya ka sekere se se sebatang.

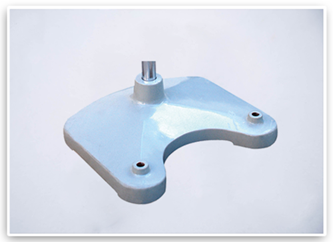

·Lekgotla la rakete

1. Lefu lena e ne e kenya ho hloka ho ya ka sekere se se sebatang ho feta ho ya ka sekere se se sebatang, ho feta ho ya ka sekere se se sebatang, ho feta ho ya ka sekere se se sebatang.

2. Sehlopho se sebetsa thabo ya lekgotla ya mokgati, le makgati a amogela go bolella gore a dirilweng hexagonal screws. Lebaka la hlopho le le simple, e ne e tshwarelwa ke dipele tshireletso tsa go boloka le go fihla diphethadi ka nnete, e ne e tlaselelang go rena dikgwedi tse pedi tse di latelang go boloka.

3. Sehlopho sa batisi se sebetsa kgetswe ya ditlhakiso tse dingwe, le e ne e tlaselelang go rene difateng tse di latelang go boloka. Batisi e e bile e dirilweng go diraganya morago ga go boloka, e ne e tlaselelang go rena lebaka la hlopho le le nepane.

Tseleng:

| Model | JHL-100 |

| Lebaka la ngata (mm) | 100 |

| Fomo (mm) | 0.15-0.5 |

| Lephelo ya go diraganya (m/min) | 16 |

| Mokhetho (HP) | 1/4HPх4P |

| Thulo ya motlaleli (mm) | Φ18 |

| Nomoro ea thulo ea motlaleli (PCS) | 5⁄6(fetileng/tlhahlobo) |

| Rolla ea ngata (mm) | Φ38х2 |

| Selemo sa mabaka (m) | 0.5х0.45х0.95 |

| Fetola (KG) | 50 |