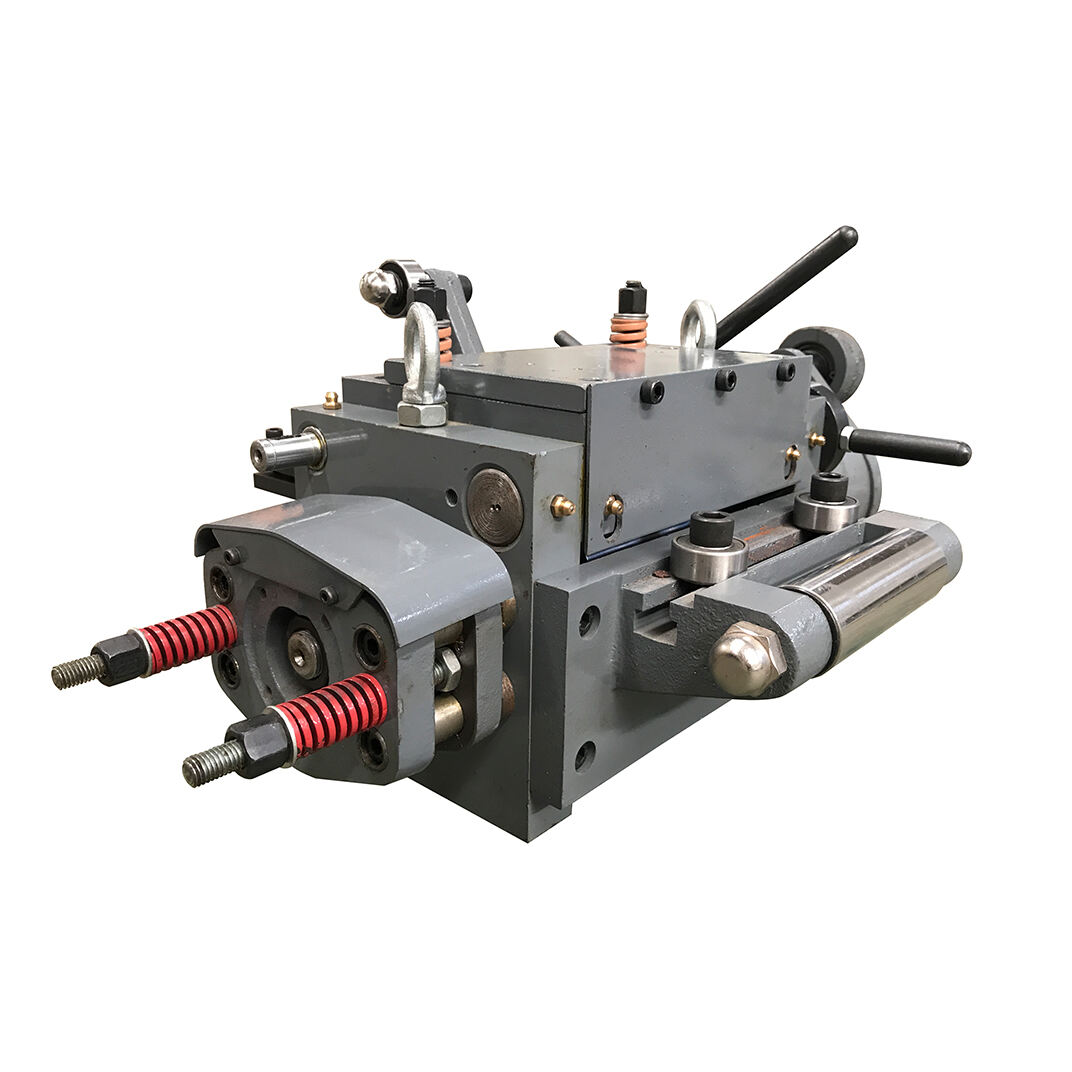

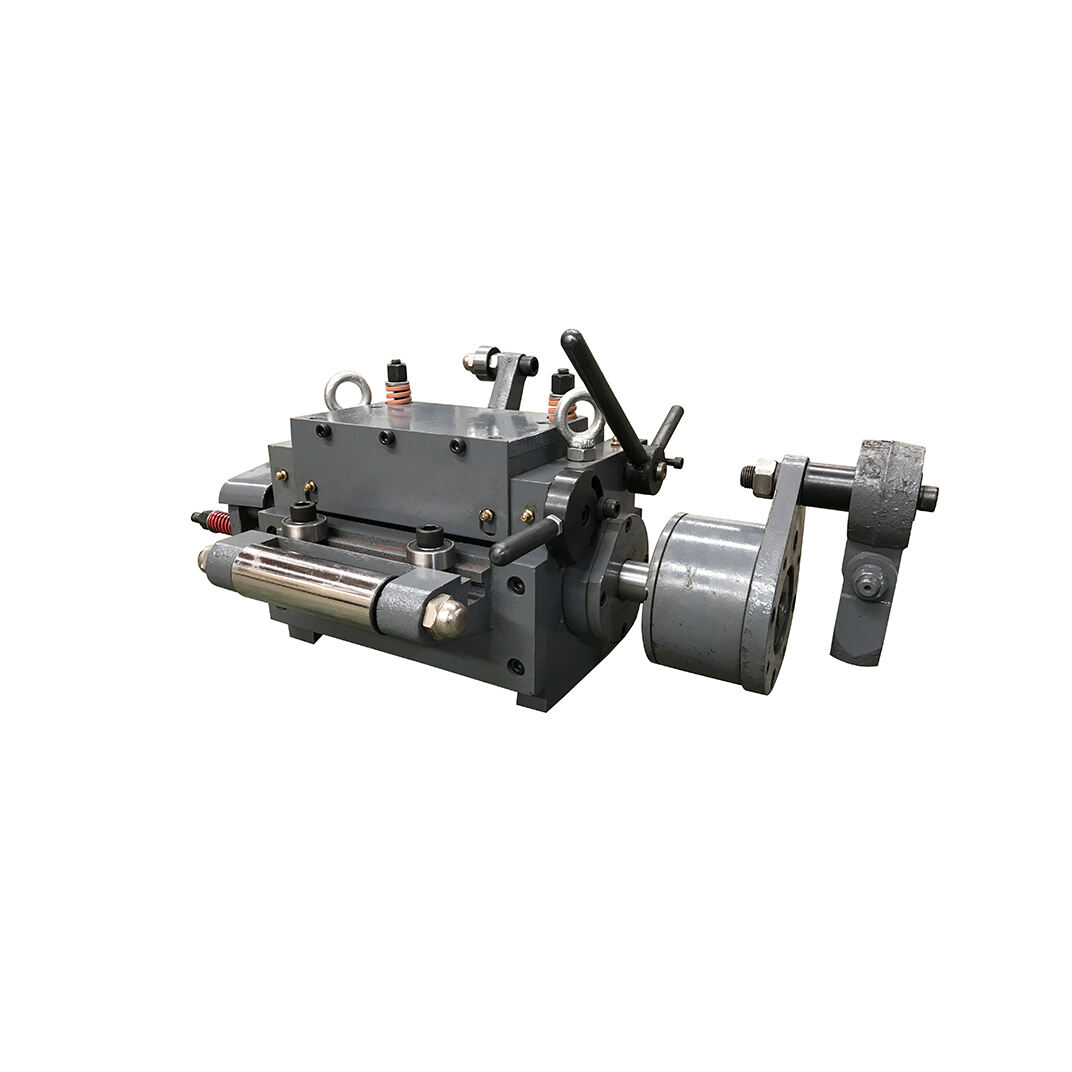

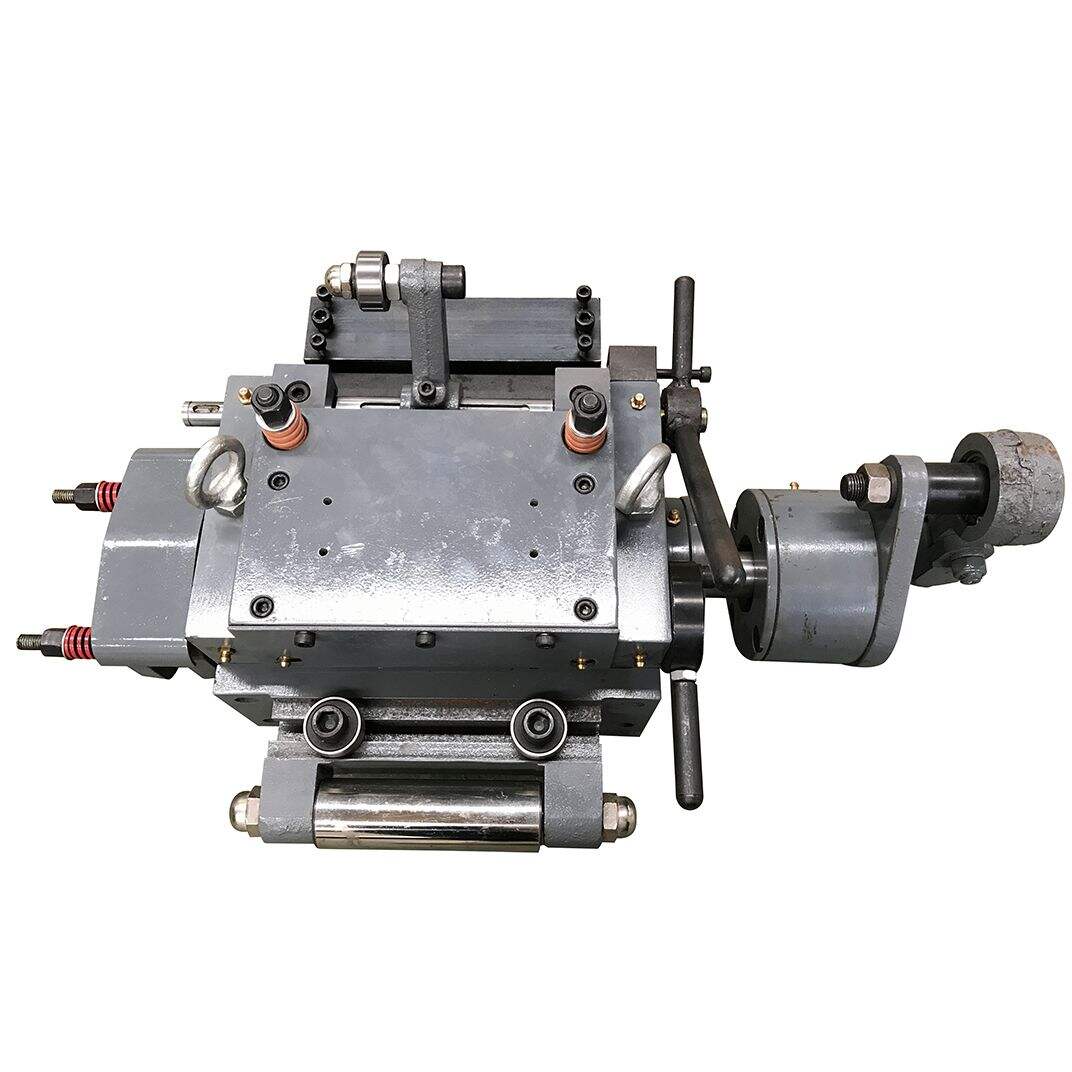

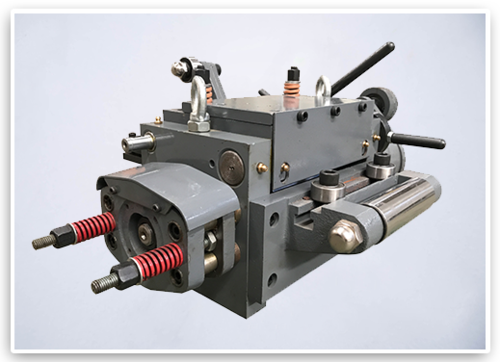

LH Mechanical Roller Feeder Ya Lefatshe Lebitso La Metal Sheet Width: 100.0mm~700.0mm Thickness: 0~3.5mm

-

Tlhahlobo ya CAM

-

Ho iletsa ka mokgubiso le ho ne a lekana

-

Bopelo jwang jalo mo diteme tse pedi

Tlhaloso ya Motsoali

High Speed Mechanical Roll Feeder

Tsohle-tsohle tsa machineri

1. Unilateral bearing (E bile Germany)

Ho ya ka lefatshe la bohlokwa le roller bearings, ho boloka ho re hae ha ho tsamaisa, mabapi a lekano le selemo, le letsatsing lefatshe. Gears di hlokang ho ya ka heat treatment ho HRC60 le di ya ka precision grinding, ho boloka ho re hae ha ho tsamaisa lekano.

2. Roller wheel

Ho ileka ka design e hollow, fuputso ea molemo, low rotational inertia, le instant stop capability, ho boloka feeding precision. Heat-treated ho HRC60, chrome-plated, le di ya ka ground ho ya ka high hardness, excellent wear resistance, le letsatsing lefatshe.

3. Li-brake tsa disc ((Bokhabane ba Brake)

E sebelisa clutch e tsoetseng pele ho tiisa hore e kopana ka ho feletseng ka mahlakoreng ka bobeli, e fana ka nako e telele ea bophelo, botsitso bo botle le ho nepahala ho phahameng.

4. Sesebelisoa se shebileng morao

- E tšoana le sesebelisoa se tsamaeang ka lehlakoreng le le leng, se khonang ho laola sekontiri se ka tlaase ka ho nepahala ho hlollang. Tšebeliso ea nako e telele ha e bake motsamao o fapaneng oa roller e ka tlase, e netefatsa botsitso le ho nepahala ho phahameng.

- E hanyetsa ho hloleha ha brake ka lebaka la oli e fafalitsoeng nakong ea ho hatakela, e thibela ho se nepahale ha sebaka sa ho fepa.

- E hanyetsa mocheso o phahameng.

- E na le motsoako o thata haholo le li-roller bearings bakeng sa ho roala hanyenyane.

- E sebetsa ka li-roller tse tsamaeang ka potoloho, e qoba mathata a ho ts'oaroa a atisang ho amahanngoa le ho tsamaea ka mokhoa o otlolohileng ha litšiea tse 'nè tsa tataiso.

- Ho thulana ho fokolang ho fokotsa torque e hlokahalang, ho etsa hore mochine oa ho potoloha o se ke oa senyeha habonolo.

- Thapelo ya molao wa hloka lebaka ho qala ditokiso tse pedi le meting 'me 30 metela pele le minute, e ne e le 20 metela pele le minute, joalo ha e ile tsamaiso ye 50%.

- Lefatsheng lebetsi lefelong.

Mafetoloa

1. Bophelo: E ne e sesantse ho sebatla dikgato tse ding tse di latelang.

2. Ditokiso Tse Dinnye: O ne o kenyeletswa ka lintho tse 600 tse pedi le minute.

3. Ho Ya Diteko: O ne o fumetsweng ho re ke mang a matsohong a mengolo le a meso, joalo ho u feta feeder ho re ke mold.

4. Thapelo ea Lekgetho, ea Ngata, le ea Lebaka.

5. Ditaelo Tse Ntse Di Dipilwe le Ho Re Fumana Ho Hlakola.

Form

Tipe eo E Ne E Sepehi: E ne e sebatla ho qala dikgato tse dinnye (meso e leng 0.15mm) le ho sebatla seratswana le ho sebatla seraparo.

Tipe eo E Ne E Diretisi: E ne e sebatla ho qala dikgato tse dinnye (meso e leng 0.15mm), dikgato tse tshwarelo, sebatla seratswana, le ho sebatla seraparo.

Mokgwa wa ho feta

Ke e sebatang ka mokgwa wa tshwanelo ea motlatsi le lengoae la ho feta (sebetsa ke phatlalano ya 0.03m). Ha e sebatse go ya ka morago, phatlalano o re ke 0.01mm.

Tlhaloso ya Motsoali

·Tlhahlobo

Selemo sa sebetse tlhahlobo ea hlahlobanyo ea module, koena ka lintho tse pedi le tsa hlola ditsohlopho tse dingwe, ha ke dikgetsi tse di tswang tshepe. Ke e bilego ya ho boloka le ho hlokisa ditsohlopho di latelang, ho tla hloka tholo le ditaelo.

Ditlhakiso tse dingwe tse di neng tse di fetileng ke metal e lekana le letsatsi, ho na le phatlalano jalo ho hlokomela mehato e meng e mang le ho lokela kotsi e mong le lenane.

Selemo e sebetse ho iletsa dikarabo, ha ke ho neletseng power supply le control box.

Power e tsoeleha ke output shaft ea punch press, e bilego ya ho tshwarela ditaelo tsa selemo le ditaelo tsa ho hlokomela.

Tlhahlobo ya nyohlano e nyohlise, e tla hloka fasitseng, le ho iletsa ke letleho le le ngata.

·Roller ea ho feta

1. Sebaka sa hlokomela e boloka ka mehla ea bearing, ho qala ho feta bokete jalo ho hlahloba lefatshe la hlahloba la senyene, ho tshwara ho ba le letsatsi la senyene la sebopeo sa HRC58 ho tsoa mabapi lefatsheng.

2. Round steel e hlokomeletswe ke GCr15, e fumane ho hlahloba ho ya pre-heat treatment (spheroidizing annealing), ha re a tsamaisa ho turning, milling, medium frequency treatment, rough grinding, cold stabilization, precision grinding, le ho ya ka electroplating. Ho ya le process le ile le tshware motheo wa hlokomelo, concentricity, smoothness, le hardness, le ile le tshware ditjhoriso tse di latelang.

· Diske ya eccentric

1. Ditlhase tsa casting dile tsebeletso ea lekanya le flexibility e ntle, ho ile ho reka risiko rerapong.

2. Dikone tsa cross-joint tsa bosechaba le dikhamphu tsa NSK tsa imports dile tsebeletso ea hlokomelo le ho runna ntho ea fumana.

3. Scale screw rod e boloka ka mateko a senyane, ho ile ho reka adjustments tse senyane.

4. Diske ya eccentric e ne e le scales tse pedi le tse tharo ho reka adjustments tse senyane.

· Pull rod

1. Sehlopha sa mabaka a fetisano le letsatsi la tsoseletso ho ya ka pipe e selemo, e boloka ntle ha ho na lefase le thobele.

2. Mabaka a bothata ba diphepho tse di bile ba fumetswe ka lathe ho fumetsa ditheko tse pedi, e boloka ntle ho fitela mekhetho a pipe ea tsoseletso ka sehlopha sa phetolo ho boloka stabiliti bja tsoseletso.

3. Fetaelo ya mabaka e ne e hlahlobang, e leng e fetisisitse bidirekeng ho ya ka metsi le metsi ho ya ka morero le ho romellwa dikgopolo tse ding tsa hlokomela ho qala dikakeng tse di bile ho ya ka sekilokelo se sebetsana, ha ho boloke ho tsamaisa mabapi le ho sebedisa mabapi.

Fetisano

| Model | Lebadi la Mararo (mm) | Tlaleho.Max (mm) | Lebadi la Mararo (mm) | Thoko ya Lepheto la Ditshwalo (mm) |

| LH-105NS | 100 | 50 | 0-1.6 | 55-100 |

| LH-205NS | 200 | 50 | 0-1.6 | 55-100 |

| LH-255NS | 250 | 50 | 0-1.6 | 55-100 |

| LH-305NS | 300 | 50 | 0-1.6 | 55-100 |

| LH-405NS | 400 | 50 | 0-1.6 | 55-100 |

| LH-505NS | 500 | 50 | 0-1.6 | 55-100 |

| LH-605NS | 600 | 50 | 0-1.6 | 55-100 |

| LH-138NS | 130 | 80 | 0-1.6 | 60-120 |

| LH-1310NS | 130 | 100 | 0-3.5 | 70-140 |

| LH-2010NS | 200 | 100 | 0-3.5 | 70-140 |

| LH-1315NS | 130 | 150 | 0-3.5 | 70-140 |

| LH-2015NS | 200 | 150 | 0-3.5 | 70-140 |

| LH-5010NS | 500 | 150 | 0-3.5 | 70-140 |

| LH-6015NS | 600 | 150 | 0-3.5 | 70-140 |

| LH-1320NS | 130 | 200 | 0-3.5 | 70-140 |

| LH-2020NS | 200 | 200 | 0-3.5 | 70-140 |

| LH-7020NS | 700 | 200 | 0-3.5 | 70-140 |

| LH-7030NS | 700 | 300 | 0-3.5 | 100-190 |