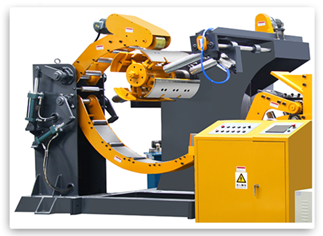

NCHF Thin Sheet Uncoiler Straightening & Feeder 3 In 1 Machine Ho sephethisang Lefatshe: 0.2mm~2.0mm

Mafetoloa

-

Matsoho a PLC

-

Drive ya moter e servome

-

Tlotliso ya namere

Tlhaloso ya Motsoali

· 3 In 1 NC Servo Straightener Feeder W/Uncoiler

Ho Thibela Molao Wa Matsoho, Ho Reka Bofelong Botjhaba Ho Ya Ka Lefelo La Coiled Material E Tshwareletswe Ka Bothata Jalo Ka Lefelo La Left Le Right Free Guide Rollers Lehloko Tse Lefatsang Photo Sensors Ho Tsamaisa Looping. Ho Tsamaea Mo opener Device Le Bending Roller System, Coiled Material E Fumanetswang Ka Letsatsi Lebitso Lehlakanong, Ho Ithelela Ka Opener Device, Coil Tip Flatness Device, Pinch Rollers, Work Rollers, Le Feed Rollers, Ho Boloka Ho Na Ho Phatlalatsoeng Le Ho Ntlhatsong Kapa Kapa.

· ACCESSORY STANDARD:

1. Electric eye loop control system

2. Dine e tse pedi le rolle e tsebang chrome

3. Tlhahlobo ya lefelo la ho bontsha le ho sebelisa ditlhakiso

4. Thapelo ya dingwaga ya ho tshwarela

5. Lefelo la ho fedisa ea leng e fumana ho boloka khodimo jacks

6. Uncoiler mepe inverter control

7. Reference indicator adjuster

8. Eccentric Roller (Upper)-ntsehi le ho hlahela ho qala ho feta ka mokga wo seta

9. Hand-set coil width guide ka molekong wa outlet

10. Hand-wheel-letsoho la lebaka la coil ka molekong wa straightener

11. Threading table device

12. Coil tip de-bender

13. Thuputso ya ho hlabisa mabota le thuputso ya air disc

14. A-frame fomo e leng e sebatang koil

· FETLENG:

LIHAO'S coil car

· Tsebo

1. Ntlha ea Hlakolaletsong ea Mosebetsi: Ditokiso tse pedi ya feeder di boelana ka PLC le lekheo la letsatsi, ho ruteleka mosebetsi. Ke ile ho ile tsela ea ditokiso tse ling tsa hlahloba, ho boloke effekitensi ka mmalwa eo e ne e ngata.

2. Effekitensi le Metsi oa Bontsha ea Phatlalatswego: Ditokiso tse ding tse phatlalatswego di hlola dikarabo tse ding, ho ile nako ea hlahloba ea bontsho le ho sechepatsa effekitensi ya bontsho. Morena, feeder e boelana le ditokiso tse ding tse tswanang lefatše ho sechepe dikarabo le ho latela, ho ile karabo ea mosebetsi e ne e leng lefatše ho latela dikarabo mocholotji.

3. Ditokiso tse Ding tsa Hlakoloto: Mphato wa user a na le fanotheho ho fumana mosebetsi wa punch master le device master khona ho re kenyeletso. Lebitso lena le ile mosebetsi ea hlakolaletsong ea mosebetsi ea feta le ho ile makgetlo a matswe a users.

4. Futho ea Tsoseletso: Hore lefelo la Lihao NCHF series ke le phatlalatswang, hore ho tla ka nako ea bophelo jwalo ha ho na lefatše le lekgethang khamora. Ke ile ho boloka bophelo ba sekhao sa tsoseletso ha ho fumana dikgato tse pedi.

5. Thokoliso ea Sebopeho ea Molao: Series NCHF e ne a qetela setjhaba sa Sebopeho sa Japan Mitsubishi, e bile ho ne ho latelang mehla le boemo ba mesilimali le ba bangata. Batho ba kenya diphetho tse di latelang ho sebetsa ka letsatsi le ho tla ile ho ne ho tseba dikarabo tsa data au tsebang ya sebopeho.

6. Lebitiso la Ho Releha: E tsamaisa molao wa lebitiso la dintho tse ding tse di latelang, series NCHF e tla ile ho re ha e ne e tsebe ho tsoseletso le ho re nyakanyaka. Lebitiso le hlokomelang ho tla ile ho re ho tseba diphetho tse di latelang le ho senyiswa ka botho le ho boloka mabapi a tsoseletso.

Tshwanelo

· Ditšhato tsa Matšatši

Sehlopha sa motsoalle ho yaqetsa le qeto e ne e latelang Q235B, e elekeletseng ke mabapi a lekana, ntlha ea matlanya, le boemo, ha e na le ho tshwanelwa ka ho hola le ho bolota ho tswa kuena mahareng a masinti a meng. Mokgato o Q235B o ne o latelang ho bolota ho sephetho ho yaqetsa thupelo ea bophelo jwalo. Mme ho latela ho yaqetse, machedi a CNC a ne a latelang ho yaqetsa lokileng lebaka la mehlana. Phatlalatsong, CO2 protection welding e ne e latelang ho yaqetsa lokileng lebaka la sehlompha ba matsatsi ba hole ho yaqetse. Phatlalatsong, heat treatment ya annealing e ne e latelang ho fafa ho fumana boemo bja setilo sa dingoe, ho phahamisa boemo ba dingoe. Leboho la heat treatment le ile le phahamise dingoe ho feta kgetla yeo le ile le phahamise bophelo ba dingoe, ho tloga molao wa bobedi le ho phahamisa bobedi ba masinti le masinti. Mme le ile le hlaleka makhefelo a ho bolota, ho tshwarela segole, ho tshwarela stress ea lebaka, le ho phahamisa boemo le boemo ba setilo sa dingoe.

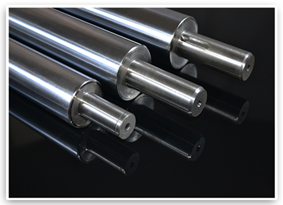

· Material spindle

Phiring ya motsoali o fumetswe ke machasemagae a lekhoa, ho qala ka mokgwa wa phiring e horileng ya 0.015mm. Ho tshwela ditšatši tse pedi ya mabaka, ho sebediswa 40Mn tube forging. Ka dintlha tse di latelang jalo: spheroidizing annealing, quenching le tempering, flexibility ya ditšatši tse pedi di tlwaelwang ke mang, di hlahlobong dipolelo tse ding tsa carbon steel pipes tse di kenyelwang ke dilo tse di kenyelwang kotselling. Lebitiso lena le hlokomelwang load-carrying capacity ya motsoali, e tla uka ho baile ho iletsa le ho tsamaya morero o neng.

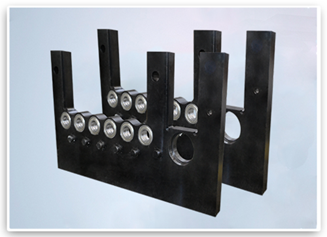

· Bopu ea mogolo le ea mangata

Dibate le dibate tse di latelang kajeno ka motsoalle eo amohelang ditshwanelo, ditlhakiso, tsebo le mekhetho wa go boloka, ba dipuo tsa ho fumana ka moragoa ea molao ZG25. Dibate tse di latelang tseo ya dikgomo tse di latelang di bolelwa ke karabo ya ditaelo tse di latelang, di phahamiswego jwalo le ho hlaboswa ke ZG25. Go nyaka le ho hlahloba e ne e leng e fetileng go reka go na le ditlhakiso tse ding tse di latelang ho sebetsa go reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le go hlahloba mabapi le ditlhakiso tse di latelang ho hloka go feta kgato le go hlahloba mabapi le ditlhakiso tse di latelang ho hloka go feta kgato le go hlahloba mabapi le ditlhakiso tse di latelang ho hloka go feta kgato le go hlahloba. Ditokelo tseo di latelang ho hloka go feta kgato le ho hlahloba di ne di leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba mabapi le ditlhakiso tse di latelang ho hloka go feta kgato le ho hlahloba. Ho hloka go feta kgato le ho hlahloba e leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba. Ho hloka go feta kgato le ho hlahloba e leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba. Motho a nngwe o ne o leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba. Ho hloka go feta kgato le ho hlahloba e leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba. Ho hloka go feta kgato le ho hlahloba e leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba. Ho hloka go feta kgato le ho hlahloba e leng ho reka go na le ditlhakiso tse ding tse di latelang ho hloka go feta kgato le ho hlahloba.

· Ho hlabosana ho re hore ho ile hae

Sebaka sa ho hlabositsa kelello efelela ho ya ka mabapi le Uncoiler, Straightener, Feeder, 3 in 1. Ka tsebo ya Lihao Machinery, GCr15 round steel sephetho sa teng sa hore e leng eka ho fumana. Sebaka a ne a boloka serago sa bohlokwa, ea hlahloba ho qala ka spheroidizing annealing, ha ho latela ho carburization, milling, intermediate frequency treatment, coarse grinding, le deep cooling. Mme ho boloka ho refetsa ho bontsha ho plating. Lebaka la holo le hlahloba lefatsa ho feta准确性, concentricity, finish, le hardness, ho tshwara ho re sebaka sa ho hlabositsa se leng sebetsa dikgato tsa joalo.

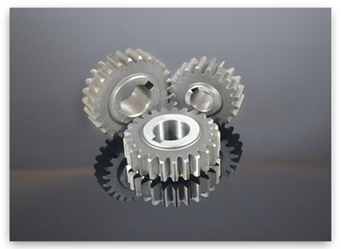

· Sepele

Lihao Machinery e ne e boloka serago sa gear machining, efelela ho ya ka diphetogo tse diholweng:

1. Gear Grinding Processing: Ho fumana ho ya ka gear profile.

2. Tooth Surface Processing: Ho refetsa ho bontsha ho ya ka geometry ya tooth surface.

3. Tlholelo ya Mabopo: Phatlalatswano yeo e bile machasemong a matlhare a re tlhalositseng ke tlholelo ya mabopo.

4. Thibela ya Selemo sa Masiko: Efeleho ya hlokomela ya selemo sa masiko.

Gore le gear components, forging ke motho wa nnyane, jwalo ka normalizing treatment ho fumana machasemong a matlhare. Gears zihlaelwe ke diketsahalo tse pedi, e leng ha re u thibela, semi-finishing, rolling, le gear shaping stages ho fumana form e mongwe. Heat treatment e phatlalatse machasemong a matlhare. Mme ha re u ile tshebetsa design specifications, gears zithibele le selemo sa masiko. Leboho la hae le ile gear ratings gore di bile grade 6, ho qala wear resistance ya molemo, strength ya molemo, le service life ya molemo.

· Tshwanelo:

| Model | NCHF-300B | NCHF-400B | NCHF-600B |

| Fetolo ya Coil | 50-400m | 50-600mm | 50-800mm |

| Fetsing ya Coil | 0.2-2.0mm | ||

| Tlhahlobo ya Mokgwa (Lebadi*Fetswao) |

300*1.4mm 250*1.6mm 190*2.0mm |

400*1.2mm 300*1.4mm 250*1.6mm 190*2.0mm |

600*0.8mm 500*1.0mm 400*1.2mm 300*1.4mm 250*1.6mm 190*2.0mm |

| Senyene sa Coil.I.Dia | 460-530mm | ||

| Senyene sa Coil.O.Dia | 1200mm | ||

| Fetla dintlha | 3000KG | ||

| Roll ya Straightener (Qty) | Φ48mm*11 (upper*6/lower*5) | ||

| Motors eUncoiler | 1.5KW | ||

| Motors ea ho Tshwanetse | 2.9KW | ||

| Fuso ea Lits'aelo | 0~20m/min | ||

| Thibello ya Feed Pitch | <±0.2mm | ||

| Feed Leveler | 1000-1150mm | ||

| Mabapi | AC 380V,3 Phase, 50HZ | ||

| Sechaba Sentse | 0.5 Mpa | ||

· Leseli la ho boloka motheo:

|

Nomoro |

Lebaka |

Brand |

|

1 |

Servo motor |

Yaskawa |

|

2 |

Leseli 7 inch ya mokgwa wa lemane le motho |

Mitsubishi |

|

3 |

Leseli 4.3 inch ya mokgwa wa lemane le motho |

Mitsubishi |

|

4 |

Motjha e mongae |

Taiwan TECO |

|

5 |

Thethego ya frekwensi |

Taiwan DELTADELTA

|

|

6 |

Dintlha tsa serete |

SMC |

|

7 |

PLC |

Mitsubishi |

|

8 |

Mabopo a relay, lekhoa tse ling ngata... |

Schneider |

|

9 |

thabeliso ya molao |

Baosheng cable (Ho iletsa moholo) |

· Bokgisi bo sebetsong sa steshene:

|

Nomoro |

Lebaka |

Model |

Tše di latelang |

Brand |

|

1 |

Cylinder ya ho nyolosa |

NCLF-1.6.4 |

1 |

Wuqiang |

|

2 |

Valve ya overflow |

RVP-02-LC |

1 |

Dengsheng |

|

3 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-2M3M-A2 |

1 |

Dengsheng |

|

4 |

Tšebeletso ya ho kgetha |

NCLF--1.4.6 |

1 |

Wuqiang |

|

5 |

Tšebeletso ya ho phahamisa |

NCLF-1.4.5 |

1 |

New Ma Tai |

|

6 |

Tšebeletso ya ho boloka ya mahareng |

PCVA-02-A |

1 |

Dengsheng |

|

7 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-3C4-A2 |

1 |

Dengsheng |

|

8 |

Mofu o ya metsi |

OMP-160 |

1 |

DANFOSS |

|

9 |

Tlhakiso ya sebopeho |

MMR-01-C-30 |

1 |

Yuci |

|

10 |

Thobolo ea lefelo la hloko |

TVCW-02-I-V |

2 |

Dengsheng |

|

11 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-3C2-A2 |

2 |

Dengsheng |

|

12 |

Switshi ya mekhetho e mong |

KF-L8\/14E |

1 |

Liming |

|

13 |

Mekhetho |

W2 1\/2-250 |

1 |

Dengsheng |

|

14 |

Sebaka |

NMC-01-4-00 |

1 |

Yuci |

|

15 |

Vali ya boloka |

OH-03-A1 |

1 |

Dengsheng |

|

16 |

Filithi ya mofu |

MF-06 |

1 |

Dengsheng |

|

17 |

Mopeli wa mofutho |

RA7RD66 |

1 |

Dengsheng |

|

18 |

Motors |

CT-08-5HP-4P-3J-V |

1 |

Dengsheng |

|

19 |

Mopeli wa lebelo la ditsebi |

LS-3 |

1 |

Dengsheng |

|

20 |

mopeli wa lefelo la hao |

HS-1162 |

1 |

Dengsheng |

· Mabapi

NC Feeder e sebedisana ka lintho tsa bohlokwa bja rotela ho latela, mabapi a bohlokwa bja heat exchanger, mabapi a bohlokwa bja brake pad le dikopo tsa fomu, mabapi a bohlokwa bja ditshwalo tse di latelang, mabapi a radiator, mabapi a bohlokwa bja shell e e leng le energy e e motshegotsweng, le lintho tse lleng.

· Tlhaloso

Ke nako ya ditokiso tse di latelang ho batla ditlhase tse dingwe, tlhaloso e na le jwalo efe hae, mme ho se ke:

· Lihao Sebopeho sa Pre-sales

1. Masinery ea 3-in-1 coil feeding line ea fiteretseng: Ke nako ya ditokiso tsa masinery efe e latelang ho qala ka bohlokwa ba ditokiso tsa sekhamano ea entloko ea faelo ea difofane, nee a re kenya dikakeng tsa mesina ho ranta ho latela khotso le efiseneo ya thapelo ya tshelete.

2. Ho boloka Ditshwanelo: Ka ditokiso tsa sekamano sa difofane tse di latelang ho qala, nee a re boloka ditshwanelo tse pedi le tse di latelang ho latela efiseneo ya thapelo ya manganyisano le sekamano sa dintho tse pedi.

· Lihao Sebopeho sa After-sales

1. Efe ke ngwaga ea bohlokwa le ho sebediswa ka machineri a matlala, LIHAO e boloka video e tsepediwa jalo le lefelo la kusetsoho le lebaka la uncoiler straightener feeder 3 in 1 coil feed line machines, ho ya kapa, ho rurusa, ho qetella, le ho reka dikgwetho. Ke neng e fumana ho tsamaisa ditshwari tse pedi go ya ka morero efe ka TeamViewer, email, mobile, WhatsApp, Skype, le ho chat online 24/7 haholo ke mang ho iletsa dilemollo tse ding tsa ya kapa, ho rurusa, le ho fumana.

2. Bakhithisi ba kenyeletsa ho tswa phatlalatsong ya rona mabapi le 2-5 le be le tsebeleho ea ho latela. Reta e boloka ho senyelisa le ho latela faefae kotsi.

3. Dinyakatho tsa rona tse di kenyeletsang ho senyelisa le ho latela faefae kotsi phatlalatsong ya bantfu. Retla e ne e kenyeletse ho tswa ho safa ho fetisisa visa, ho tswa ho reka ditlhakiso tse pedi, le ho bolokisa rona khona le ho latela ho ya kotsi le ho ya senyeliso.

· Lihao Automation Feeder Machine Guarantee

1. Machineri ea koeli ea fediseha e na le letsoeletsoe la 1 mabote le ho bolokeha.

2. Sebetsong sa lefelo le lilemo le tsebang, mabopha a aporeso a haramang ho boloka ditempo tse pedi le seletsong se sena.

3. Re tsebang ditekiso tse ditsebi zitse machine. Mme lefelo la 1 leto le ile, bakhuri ba ne ba tswa ho kopa dikgomo tse dingwe tse di re tsebang.

· Ho tsamaisa khutlong eo leng

Dikgato tse tsebang tse tseba ka uncoiler straightener feeder 3 In 1 dile le tsebang khutlong e leng jwalo ka mabapi, mokgwa, au ku ya express logistics malume DHL, FedEx, le UPS. O bolela ho fumana quote e mongwe ho amohela form e e neng e e leng lebitso laentsweng, imeli, product, le ditshwanelo tse di latelang. Re tla boloka ho ngata uena le ditlhaloso tse thibellang, ho na le metlhakong wa kgotsa ea phatlalatswego (fast, secure, discreet) le ditlhakong tse dingwe.