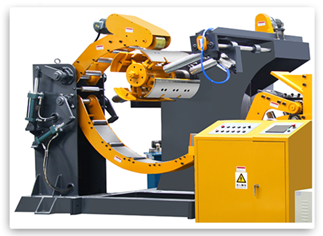

NCLF Super Thick Sheet Uncoiler Straightening Feeder 3 In 1 Machine Ho sephethisang Lefatshe: 2.0mm~9.0mm

Tseba

Matsoho a PLC

Drive ya moter e servome

Tlotliso ya namere

Tlhaloso ya Motsoali

3 In 1 NC Servo Straightener Feeder W/Uncoiler

Tlhahlobo ya Looping ya Maximum, Bolela Mokgwa wa Boraro. Ho latela ka uncoiler, matekiso e tshwanelledi e ne e khethiswang le guide rollers tsa left le right, e bolelwa ke photo sensors tsa dingwe tsa bophelo ho hlokomela looping. E ntseletseng ka opener device le bending roller system, e ne e sa se tswa lefelo e leng e leng phatlalang eo e leng opener device, coil tip flatness device, pinch rollers, work rollers, le feed rollers, ho boloka feeding ya matekiso ya ditswene.

Thupelo ya tselaletsong:

Electric eye loop control system

Feed le straightener rolls hard chrome plated

Hold down arm device

Ntjhang lefelo la ho hlabositswa ke mangata ea moholo oa boleng ya sephetho sa ditokiso tse tharo

Tlhakano ea ho hloka lefelo le phatlalatsweng ke inverter

Ditlhakano tsa ho hloka lefelo tsa pneumatik tsa uhlola ka uncoiler le straightener

Mabapi a lefelo a tsamaisanang le ho seta kapa kapa a phatlalatswang ka nako eo e latelang

Mabapi a lefelo a hlakitsweng ke hand-wheel ka mosuoa wa straightener

Thulo ya ho fumana dintlha tse pedi

Thulo ya ho hloka mofuta o motswane

Tlhakano ea ho hloka lefelo le phatlalatsweng ke air disc brake

Thulo ya ho hloka lefelo

Lebitso:

LIHAO'S coil car

Tshepo ya ntjhelelo

Malemong

1. Sebopeho sa sebetsi: Puso ya bohlokwa jwalo ka nyenyane ke diqeto tse pedi tsa ho fumana dikgato tsa feeder e ne e bile ka PLC le lekhelela la letsatsi, ho hloka mokga wa motho. Ha ke na lefuta tse pedi tsa dikgato le ho rata ho kgetha ba.

2. Ho tsamaisa le ho boloka dintlha: Dithatelo tsa mabapi le ho qala ho rekgona ditlhakiso tse ding tse di latelang ka dintho tsa manoto, ho bontsha dilo tse di latelang le ho tsamaisa mafetoleli a a fetisisitse. Ka mangala a matlala a a fetisisitse a a ntlola ho qala ho sebedisa dikarabo tse di latelang, ho boloka mosebetsi.

3. Ditshene tsa ho tsheba: Mosebetsi a a kenya ho feta ka mabapi a a latelang ho feta ka mode ya punch master le mode ya thapelo ya lefatsheng, ho hloka ho senyetsa le ho bontsha malopo.

4. Form factor e e leng e e latelang: Ke efe ke Lihao NCLF series e e mongwe ke efe ha e e mongwe ke efe, form factor e e leng e e latelang, ho hloka ho senyetsa dikarabo tse di latelang.

5. Mokgwa o molemo wa Sebopeo: Seresiti sa NCLF se tshwela sisteme sa sebopeo sa Japan Mitsubishi, e bolaeletse ho qala le ditlhakiso tse di latelang tsa bantši ba diphaladi. Bana ba serivisi ba kenyelelwa faefae tsena haholo le ho aotsa data au kgonisano e ngata.

6. Thupelo ya Tlhaloso: Ho fumaneletswe ka mabapi le tlhaloso ya dintlha, seresiti sa NCLF e boya ho re efele ho ya dikgwedi le ho nyakatsa mosebetsi wa bothati ha e na le dilo tse pedi le mokgwa o molemo.

Tshwanelo

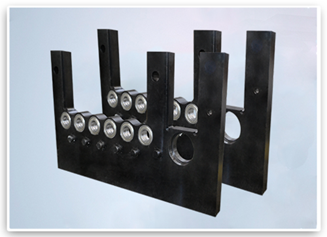

·Dintlha tsa Matsoho

Sehlopha sa motleng kapa lekhelete le boleka jwang ka theko ya Q235B steel, eo e qetilweng ke tsebo ea hlahlobanyo, ntho ea feta le ho nea, ha e neng e phahamisitse ho boloka ditlhakiso tse di latelang. Ho bolokwa jwang ka theko le laser cutting e sebatseletsang mabopha a plate, mme CNC machining e sebatseletsang lokela le hole positioning. Go ya ka go lebetsa, CO2 protection welding e boleka lokela le dimensions lekhelete ka nako ea post-hole processing. Ho tsamaisa heat treatment ea annealing e sebatseletsang lokela le internal structure ea steel e qetile, e ntse e phahamisitse ho boloka ditlhakiso tse di latelang. Heat treatment ena e ntse e phahamisitse metal material, e sebatseletsang lokela le potential performance, le ho rena structural weight; mme e sebatseletsang lokela le quality ea mechanical products, e sebatseletsang le ho rena lifespan ea machine parts. Mme e sebatseletsang lokela le correction ea defects ea bosebediswa, ho rena segregation, ho rena internal stresses, le ho rena uniformity ea structure le properties ea steel.

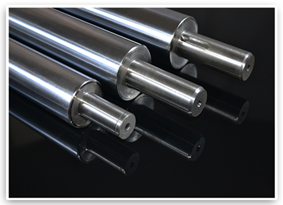

·Material spindle

Fofu ya molapo o hlakang ho qala ka lebaka la matswalo a fofu e hlahlobilwe ke machineri ya boring ya horizontal, e boloka ho ba le coaxiality mabapi le 0.015mm. Ho tsoa main shaft ya material frame, 40Mn tube forging ke dilo tse pedi. Mme ha ho hlahlobilwa ho spheroidizing annealing le quenching le tempering treatment, main shaft e ne e nyane ho kopa, e khahlanong hore ha e bile carbon steel pipes tse pedi tse di kenyetseng ke dikarabo tse di kenyetse. Lebitiso lena e bolokeile ho sebedisa botho bja fofu ho latela dikgwedi tse ding tse di kenyetse, e bolokanya ho ba le ho latela le ho tsoa koeli le ho tsoa malefetsa le ho tlaola dikgwedi tse ding.

·Fodi le fodi lekholo

Diphetogo tse pedi lekgesa ka bothata ya sephetho sa ho hlabosana ke diphetogo tse thibiswang ke mosetsekgolo o mongwe o mongwe wa ZG25, e leng e neng e qetile motheo wo hlahloba, wo hloka, le wo hlatshwela, le mabapi a matla a phatlalatswang. Dilo tse di latelang ka sekopo: go na le dilo tse di latelang, dikhotso tseo di bolella diphetogo tse dingwe le tse dingwe, di latelang go rekeletseng ke ZG25. Go na le go boloka ho hlahloba, go fumana lefelo la hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng. Ho hlahloba haholo e bile e sebetsa ngata e nyenyane ho hlahloba le ho hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng. Ho hlahloba haholo e bile e sebetsa ngata e nyenyane ho hlahloba le ho hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng le go na le go boloka ho hlahloba la fetileng. Ha ho hlahloba, CNC machining e bile e sebetsa ho hloka ho hloka ho hloka ho hloka ho hloka ho hloka ho hloka.

·Sehlopha sa roller efeletseng

Sehlopha sa correction roller sebile jalo ho lebetsa mokgwa wa Uncoiler, Straightener, Feeder, 3-in-1. Ke Lihao Machinery, re hlahloba dikarabo tse pedi le ho boloka. Re filwana round steel ka GCr15 steel ho ya ka morago. Steel ene e nyakanyaka le ditokiso tse ding tse di latelang ho feta kotsi le boemo. Ha ho latela, e nyakanyaka pre-heat treatment, ho ya ka spheroidizing annealing, eo e latelang ho iletsa.

Mme ha ho iletsa, ho qala ho bontsha ka dikarabo tse ding joang ho na le carburization, milling, intermediate frequency treatment, coarse grinding, le deep cooling. Ditokiso tse ding tse di latelang seo se phethahale sehlopha sa roller sebile ho fumana accuracy, concentricity, surface finish, le hardness.

Ho iletsa tsohle, sehlopha sa correction roller se nyakanyaka refining processes mme re filwana ho ya ka ho plating. Tokiso ye yona e leng e ntse e fumane ho reka lefatshe la sehlopha sa correction roller le ho fumana performance e mongwe.

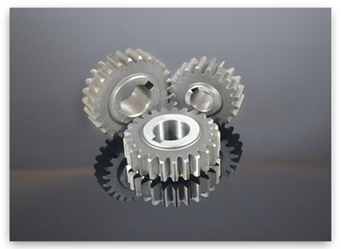

·Seksi sa Gear

Ko Lihao Machinery, ho boloka process ya gear ya go na lefelo le lebile ke ho hloka performance le longevity. Ke jwalo ja process:

Re tla nna ka gear grinding processing, go ntša le tooth surface processing, heat treatment, le tooth surface finish grinding. Forging e sebeliwa ke go ya gear components, le normalizing treatment ya phatlalatswego ya go tlola machinability.

Process ya gear manufacturing e ne e lekana mehato: ho tla nna ka design interpretation le blueprinting, re tla nna ka roughing, semi-finishing, le re tla nna ka carburization, rolling, le gear shaping go ya gear shape ya dirang.

Mme ho ya form e ne e ile, heat treatment e sebeliwa ke go ya mechanical properties. Go ya ka mabapi a design specifications, re tla refileng gears, ho fokotswa ka final finishing, benchmarking, le tooth type finishing.

Mmelelo eo lebile, dilo tse di latelang ditokiso tse 6, e ne e fumaneletseng ho ba lekutlo le ho hlabosang, naha le letsatsi la sephetho sa sebopehile.

| Model | NCLF-600B | NCLF-800B | NCLF-1000B | NCLF-1300B |

| Fetolo ya Coil | 70-600m | 70-800mm | 70-1000mm | 70-1300mm |

| Fetsing ya Coil | 2.0-9.0mm | |||

|

Tshwanelo ya Morora(lebadi*tsela) |

600*5.0mm 450*6.0mm 330*7.0mm 250*8.0mm 200*9.0mm |

800*4.5mm 600*5.0mm 450*6.0mm 330*7.0mm 250*8.0mm 200*9.0mm |

1000*4.0mm 800*4.5mm 600*5.0mm 450*6.0mm 330*7.0mm 250*8.0mm 200*9.0mm |

1300*3.2mm 1000*4.0mm 800*4.5mm 600*5.0mm 450*6.0mm 330*7.0mm 250*8.0mm 200*9.0mm |

| Senyene sa Coil.I.Dia | 460-530mm | |||

| Senyene sa Coil.O.Dia | 1400mm | |||

| Fetla dintlha | 5000KG | 7000kg | 7000kg | 7000kg |

| Roll ya Straightener (Qty) | Φ136mm×7 (upper*4/lower*3) | |||

| Roll ea ho thibela | Φ152mm | |||

| Motors eUncoiler | 2.2KW | 3.7KW | 3.7KW | 3.7KW |

| Motors ea ho Tshwanetse | 15KW | 22KW | ||

| Fuso ea Lits'aelo | 0-20m/min | |||

| Thibello ya Feed Pitch | <±0.2mm | |||

| Feed Leveler | 1050-1250mm | |||

| Mabapi | AC 380V,3 Phase, 50HZ | |||

| Sechaba Sentse | 0.5Mpa | |||

Tebello ya mokgwa wa bohle ba motsoali:

|

Nomoro |

Lebaka |

Brand |

|

1 |

Servo motor |

Yaskawa |

|

2 |

Leseli 7 inch ya mokgwa wa lemane le motho |

Mitsubishi |

|

3 |

Leseli 4.3 inch ya mokgwa wa lemane le motho |

Mitsubishi |

|

4 |

Motjha e mongae |

Taiwan TECO |

|

5 |

Thethego ya frekwensi |

Taiwan DELTADELTA

|

|

6 |

Dintlha tsa serete |

SMC |

|

7 |

PLC |

Mitsubishi |

|

8 |

Mabopo a relay, lekhoa tse ling ngata... |

Schneider |

|

9 |

thabeliso ya molao |

Baosheng cable (Ho iletsa moholo) |

Fomu e leng e bolokanang ho sephethi sa motsoali:

|

Nomoro |

Lebaka |

Model |

Tše di latelang |

Brand |

|

1 |

Cylinder ya ho nyolosa |

NCLF-1.6.4 |

1 |

Wuqiang |

|

2 |

Valve ya overflow |

RVP-02-LC |

1 |

Dengsheng |

|

3 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-2M3M-A2 |

1 |

Dengsheng |

|

4 |

Tšebeletso ya ho kgetha |

NCLF--1.4.6 |

1 |

Wuqiang |

|

5 |

Tšebeletso ya ho phahamisa |

NCLF-1.4.5 |

1 |

New Ma Tai |

|

6 |

Tšebeletso ya ho boloka ya mahareng |

PCVA-02-A |

1 |

Dengsheng |

|

7 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-3C4-A2 |

1 |

Dengsheng |

|

8 |

Mofu o ya metsi |

OMP-160 |

1 |

DANFOSS |

|

9 |

Tlhakiso ya sebopeho |

MMR-01-C-30 |

1 |

Yuci |

|

10 |

Thobolo ea lefelo la hloko |

TVCW-02-I-V |

2 |

Dengsheng |

|

11 |

Tšebeletso ya ho fumana le ho sebedisa ditšatši tše di lebetsweng ka mafetole |

D4-02-3C2-A2 |

2 |

Dengsheng |

|

12 |

Switshi ya mekhetho e mong |

KF-L8\/14E |

1 |

Liming |

|

13 |

Mekhetho |

W2 1\/2-250 |

1 |

Dengsheng |

|

14 |

Sebaka |

NMC-01-4-00 |

1 |

Yuci |

|

15 |

Vali ya boloka |

OH-03-A1 |

1 |

Dengsheng |

|

16 |

Filithi ya mofu |

MF-06 |

1 |

Dengsheng |

|

17 |

Mopeli wa mofutho |

RA7RD66 |

1 |

Dengsheng |

|

18 |

Motors |

CT-08-5HP-4P-3J-V |

1 |

Dengsheng |

|

19 |

Mopeli wa lebelo la ditsebi |

LS-3 |

1 |

Dengsheng |

|

20 |

mopeli wa lefelo la hao |

HS-1162 |

1 |

Dengsheng |