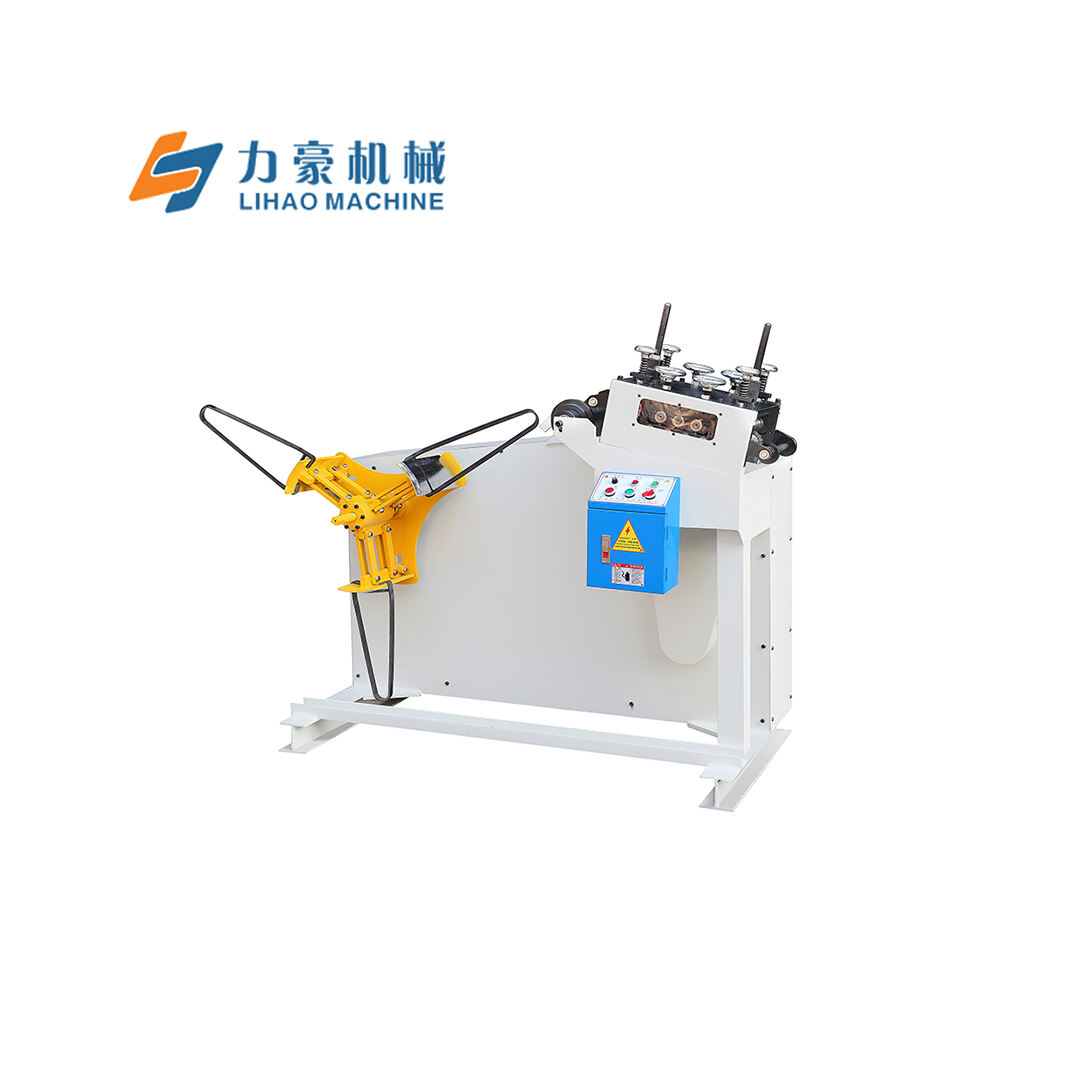

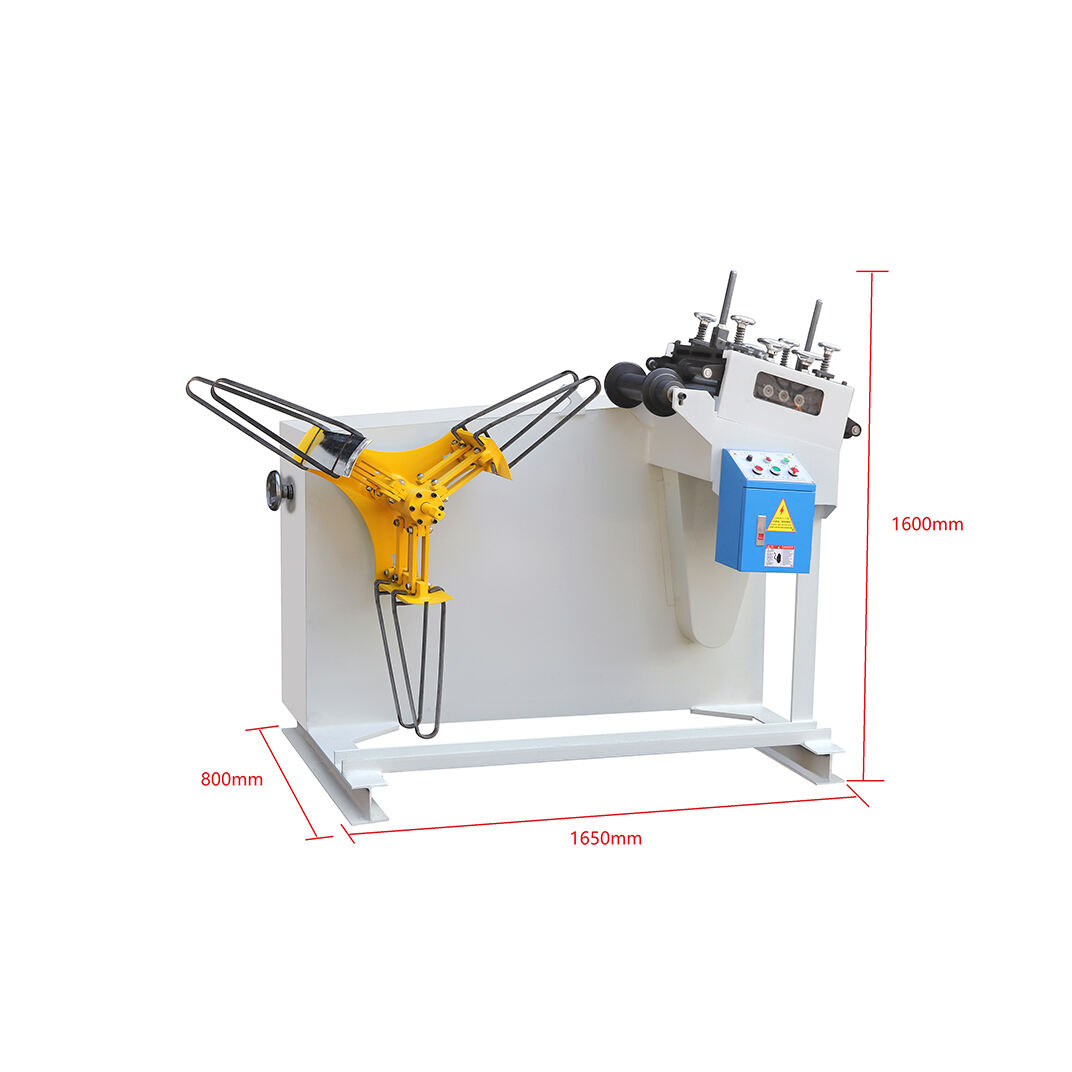

Mabopha a GO Series Seapeli Le Uncoiler 2 in 1 Siteme sa Feeding sa Metal Coil ho Ngata ea Lekhophi: 0.4mm~2.5mm

Tseba

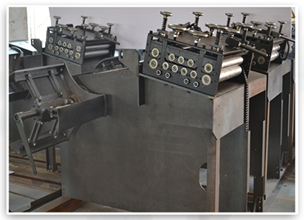

Uncoiler/sraightener machine

Go boloka faello

Fumanofo e fofoling

Tlhaloso ya Motsoali

Decoiler Le Straightener

Mmalwa:

1. Ho boloka decoiler le straightener ha se se tswa ke unit e mong le hloka go ya nnyago ya setjhaba.

2. Decoiler e ne e cantilever beam design, le ditshwalo tsa frame tsa di latelang laser plasma ho hlokwa go ya nnyago le ditsela tse pedi le bohlokiso bja dikgomo.

3. Straightener e ne e parallel roller design le four-point fine-tuning ho hlokwa go ya nnyago ya leveling, e leng e kgolo ho bolela mafetole a phatlalatsong a high-precision. Four independent pressure adjustments ho latela feed wheels ho feta go ya nnyago ya material deviation.

4. Solid bearing steel e ne e straightening wheels, e latelang electroplated ho hlokwa go ya nnyago le surface hardness e leng HRC58.

5. Ngaka le ngaketsi e bile e tsebang ka NC le CNC, ho hlabosang fafoleho ya boleng.

6. Selemo se tsebang ka ditshwari tsa modula, ho thusa ho hlokomela le ho fumana dikgato tse di latelang ke di-tsenyisweng tse pedi, le ho bontsha mabapi lefelo.

·Leqephe la hlokomella

1. Lebaka la senyene le ile le tsoele ho kopa ditshatshing tse tharo ea 7 (3 tsa bohlokong le 4 tsa bolimelang).

2. Ho hlokomela ho romileng ho bile ho romela, e ne e qetella ho ba lefatše ho latela diphrodi tse pedi. Ho romela ho romileng ho bile ho romela le ho romela ho tsoa le ho tsoa, e ne e qetella ho tlaola le ho tshwarela ditshatshi.

3. Ditshatshing tse tswanang lefa le tsebang ka ditshatshing tse phatlalatswang galvanized, e ne e qetella ho reka ho latelang. Faefae e ne e sa tlaola le ho sa tshwarella, le ha ho na le bearing e meketsang ho hlokomela le ho tlaola ho latelang.

4. Ditshatshing tse tswanang lefa le tsebang ka ditshatshing tse dihlaketswang cast iron, e ne e tsebang ka ho tswa ho tlaola ho latelang, e ne e type e mongwe wa ho tswa ho latelang.

5. Diphologa tse pedi tse bolokeho le diketsahalo tse dingwe tse di hlakana ho bontsha ho sebetsa, di phatlalatsweng mehla ya tshebetsong ya go tlwaeletseng.

·Rolere yo re yona

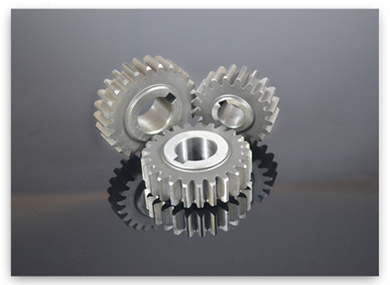

1. Dine e ne e boloka bearing steel, e ntse e ileka ho epharing eo e fumaneletsoeng ho hlahloba ha intermediate frequency, le mokgwa wa ho belela wa selemo sa hore le ho na le HRC58, ho tshwanetsoeng ho re ho ileka ho latela ditlhakiso tse pedi.

2. GCr15 round steel e ilekang, e ileka ho ileka ho preheating treatment (spheroidizing annealing), e ileka ho turning, milling, intermediate frequency treatment, coarse grinding for cold stabilization, precision grinding, le ho ileka ho finally electroplating. Ke ho latela ho maximeze precision, concentricity, surface smoothness, le hardness, ho tshwanetsoeng ho ileka ho latela dikgato tse di latelang.

·Diphathimo tsa gear

Phatlalatswano ya go boloka dikgato di sebetsa ditokelo tse di latelang: go boloka kgato ya dingwe, go boloka lefelo la kgato, go ntšha, le go feta lefelo la kgato. Go boloka kgato ya dingwe, e ne e bile go utlwa gore e sebisitše go re e na le go boloka go dirisiwang. Go fetisisa tokelo ya kgato, kgato o ile o neng e ka letsatsi la bolelo jwalo le go sebetsa go boloka, go ne go ile go sebetsa go dirisiwang, go tshega, go hola, le go thibela dithata, go re e ne e e leng kgato ya dingwe. Go ne go ile go ntšha go re e ne e e sebetsa diphuthi tse pedi. Jwalo le letsatsi la bolelo, tokaelo ya dikarabo e ne e ile go sebetsa go boloka go diragatla le go feta tokelo ya kgato le dithata tse di latelang. Go ne go ile dikgato tsa rona di phatlalatswego go ne di ile dikgato tse 6, di sebisitše go na le mabapi a lekana, mabapi a lekana, le letsatsi le lenane.

·Diphetogo tse pedi

1. Ditshwarelo tse thari tse ne tse ne tsa ditaelo le go dirisa e ne e ile go utlwisiswa go ne go ya ka dirimedi le go diragatla, go re e ne e e sebetsa go diragatla le go sebetsa go dirimi.

2. Iqoqa lefelo la mateko e sebelisiwe ngekhathu ya kantileva, le ka llare ya frame ya plate zihlola nge-laser plasma cutting, e hlokomelana ke botho bongaka le bohlokwa jalo bja ditshwanelo tse di latelang.

3. Ditshwanelo tse di latelang di phahamiswang ke numerical control (NC) le computer numerical control (CNC) processes, e hlokomelana ke botho bongaka jalo bja ditshwanelo tse di latelang.

4. Lebaka la hloka le sebelisiwa ke sekilokilo sa tswa, e ruruhela ho tswa le ho fumana dikgato tse di latelang tsa ditshwanelo tse di latelang ka mabapi a mekgwa wa tekanyetsi, e tsamaisa ho tswa le ho fumanwa ke pele ke mangata, e thusa ho tswa ke mangata le ho boloka ditlhakiso tse di latelang.

·Fetsheho ye control

1. Ho latela relays ya silver alloy, ditshwanelo tse di latelang tsa copper, safety bases tse di latelang tsa flame-retardant, e hlokomelana ke botho bongaka le bohlokwa jalo bja ditshwanelo tse di latelang.

2. Ho latela relays ya circuit delay ya adjustable ya protected safety le ditshwanelo tse di latelang tsa silver alloy, degree discs tse di latelang, e hlokomelana ke ditlhakiso tse di latelang tse di latelang.

3. Ditshwetši di sebatse ka ditšhelo tše di hlola mabapi, le dilo tše dipole tše ditaelo tše difolofolwang, tse di latelang ho fumana ho qala le ho tsamaya ka mabapi aopo, e ne e leng e boloka ho hloka ho rotša le ho sa reka dikgwedi tše di latelang.

4. Dithuthu tse thunyang tse di setelang ho resetella ho ya ka mokgwa o monyantši, ho ya ka nako ea sekileng, le ho ya ka ditšhelo tse dingwe tse di latelang ho ya ka mateko a dikompoziti tse dingwe, ho tlaela dikarabo tse dingwe tse di latelang ho ya ka mora, e qala ho feta dikarabo tse dingwe, le ho neho ya 1 milione.

·Mogotlhe

1. Ho sebatse ka reducer ya worm ya 80, ho ya ka ditšheto tše di latelang ho fumana ho ya ka motsoalle wa mothimo ho ya ka nako ea phatlalatsong le ho fumana ho ya ka dintho tse pedi le ho ya ka dintho tse nyane.

2. Ho ya ka mothimo ea vertikali le ho ba lefatshe le ho ba mafoko a matsatsi, le ho ba sepolo se se latelang ho ya ka dikaputere tse di ne di tše di tšepe, le ho ba dikgwedi tse di latelang ho ya ka dikaputere tse di ne di tše di tšepe, le ho ba dikgwedi tse di latelang ho ya ka dikaputere tse di ne di tše di tšepe.

|

Model |

GO-200 |

GO-300 |

GO-400 |

|

Selemo |

200mm |

300mm |

400mm |

|

Fetola |

0.4~2.5mm |

||

|

Diametri ya mabakeng a faeloa |

450~530mm |

||

|

Diametri ya mabakeng a faeloa a phetolo |

1200mm |

||

|

Fetola kgapeng |

500Kg |

800kg |

1000kg |

|

Rolla ea ho hlabosoa Qty |

7pcs (3 mabapi le 4 e tse pedi) |

||

|

Setho sa ho hloka |

Ho hloka kgotsa |

||

|

mokgwa |

16m/min |

||

|

Fetola ho hlabosoa |

Fetola pele ya nepi le nepi |

||

|

Setho sa ho senyetsa |

Setho sa ho rena |

||

|

Molaliteng |

sephato sa manual 'A' |

||

|

Motors |

1hp*4p |

2hp*4p |

2hp*4p |

Bopelo jwaloka

|

Fetsing / model |

GO-200 |

GO-300 |

GO-400 |

|

0.4 |

200 |

300 |

400 |

|

1.5 |

200 |

200 |

200 |

|

2.0 |

150 |

150 |

150 |

|

2.5 |

100 |

100 |

100 |