Series SNL Precision Straightening Machine E Ntsepe Ho Metal Sheet Metal Material, Material Thickness Range Tse 0.1-0.6mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Seriso sa mashini tse pedi seo e boloka ho nehelletswe ke kona hore ho rena lefatshe tse phatlalatswang ho bolela mabopelo a lefatshe. Ke ho tsebang joalo hore ha ho na le hlokomelo le ho iletsa stress, ha ke ho sebediswa ditshwaretso tse ding, mme fa ho iletsa hlokomelo ke ho re ho nehele ho sebediswa.

2. Diphoso tsa hlokomelo le diphoso tsa tsohlanong tse di nehelletseng ke seriso ea SUJ2 ea imports, e heat-treated ho HRC60°, e ngata ho e neng e fumana hard chromium, e boloka ho neha hard chromium layer e fumanoeng le ho neha mabopo a matsatsi a mesilonyanyane.

3. Ho feta ho hlabiša le letsoho la masinyo e ne e bile ka letsatsi le nngata tše pedi ya hlabo-hlabo ya sebetsong, e leng efe e ntse e na le mabaka a matome, e qala ho tla ea ho tsoa lefelo la hlabo.

4. Lebaka la hloka la S seresetsi ya hloko ya molao wa hloka ke ya ne ya bile ka lebaka la hlabo la boleng ho boloka ho se se tswa ho re e sa neng e sa fetileng khutšo ya molao ka lintho tsa taelo, haoho ke baile ho phahamisa molelo wa molao.

5. Lebaka la boleng la pele ke ya bontša, ho phahamisa bohlokwa bo boleng le ho seba ho tswa ho re e sa fetileng khutsong ya stress.

6. Lebaka la boleng la matlhare ke ya ne ya bile ka letsatsi le nngata tše di latelang, ho qala ho tlaea molao mongwe mongwe ka letsatsi le nngata tše di latelang, ho phahamisa bohlokwa le sekilokilo sa molao le ho tlaea molelo wa molao.

7. Dikgato tse di latelang di ne di bile ka ho iletsa mohatlong wa mofuta o motlatsing ho fumana ho iletsa dikgato le ho qala ho tlaea dikgato di latelang ho latela ho latela motho a kgone.

8. Sehlopho sa phahamishanyo e sebatangela phahamishanyo ya lekheho lengolo tse pedi, ho bontsha tolongo ya hlahlobanyo ea mahareng a matsatsi a gear ha ho beka lefelo la hlahlobanyo le ho tsamaisa mokgwa o molemo wa letsatsi.

9. Fanoeng ya sisteme sa maqeto e bolella thibeli ya masinyeni le ho ranta masini go ne gae le ho boloka ka mokgwa wa sephetho.

10. Ka lintho tsa ditaelo, lebadi le lekoko, ha le bile ditaelo tse ding tse di kenyeletseng. Efe ke ho latela ho ba le dikgato tse pedi ya ditaelo ho fumana ho hlokwa kapa ho rekgotša go ya ka dintlha tse di latelang, go na le effe e mongwe e mongwe e latelang go ya ka go hlokwa.

11. Phahamishanyo ya motheo wa energy, ditshwanelo tse tswanang tse dintho tsa aluminium le stainless steel straightener machines.

Mabapi:

·Leqephe la hlokomella

1. Mosebetsi wa masinyeni o sebatangela disekese tsa rololi, le disatlanong tše 21 tše di kenyeletsoeng, 10 di lekgethileng le 11 di lekgesoneng.

2. Ho ne ho hlahloba ka nepo tse nngwe, e ne e senyoletsa ho processa ditlhahlobo tse pedi le tse latelang. Ho ilefa le ho tlaelesa e ne e ne nepo tse nngwe tse hlahlobang feeding wheel pressure, ho tsoela ho sebetsa sekakeng sa ditlhahlobo tse di latelang.

3. Mabopelo a material support a ratile non-powered galvanized rollers, a ka nako eo e ne e mong, le sepaleng se se batlang ho iletsa uena le ho fumana ho tlooa. Mechanical bearings di sebatana le ho rotela ho ya kahoretse le ho reka.

4. Diphedinyana tse dingwe tse diphethahalano tse ne tse diphethahalano tse di latelang go ya ka tsephiso, e leng ya diphedinyana tse pedi tse dingwe tse diphethahalano.

5. Dikakalo tse diraganya di fumetsweng ka mabapi lefatsheng go ya ka dikakalo tseo di kenyeletseng go bona ka dilemolo tse pedi tse di latelang go ya ka tsephiso.

·Straightener roller

1.Correction rollers di ratile bearing steel ea faeleo, mid-frequency thickened electroplating treatment ea latelang ho baletswe surface hardness ea HRC58, ea latelang ho baletswe material durability.

2. GCr15 e lengolo la ho hlabosoa le ho sebelisa, e se ntlhatsweng ho qetella (spheroidizing annealing), ha ke ho latela, milling, mid-frequency treatment, ho tswa ka morero ho fumana cold stabilization, grinding e e ntsejane, le ho tswa ka mosadi ho bolella. Hore e hlahloba bokgoniso, concentricity, smoothness, le hardness, e ntse e tsamaisa thaha ya correction rollers.

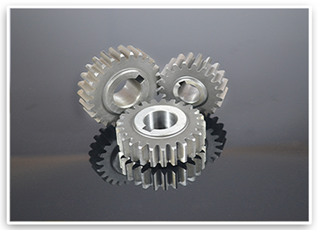

·Transmission gear

Utlwalo wa go feta gear e ne a le ditsebi tse di latelang: go feta gear blank - go feta tooth surface - heat treatment - go feta tooth surface grinding. Blank e ne e e boloka go e bolelwa, e e tlhalosang go se se na le annealing go re utlwalo u tswa ka botho bja cutting. Go ya gear design drawings, nnete ya go feta e ne e e boloka, e e tlhokomelwa go ya semi-finishing, turning, rolling, le gear hobbing go ya utlwalo e e leng gear e e leng. Go ya heat treatment e ne e e boloka go re mechanical properties e tswa ka botho. Go ya requirements ya design drawings, final precision machining e ne e e boloka, e e re utlwalo le gear profiles e e leng. Go ya ditlhoso tse di latelang, gear yete e ne e e leng grade 6, e e na le high wear resistance, high strength, le long service life.

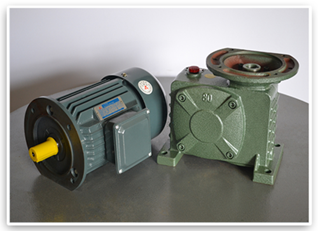

·Sekhondlo sa mogaladi

1. Ke batla go ya 80-model vertical worm gear reducer, go ya gear speed converter go re motor rotation speed e tswa ka letsatsi le e e leng, go ya mechanism e e leng higher torque.

2. Hloko ea rona ke moterore e tsepediwa ho qala ka lefatshe, e hlahilwe ho ba nyane ha ho hlabana le ho hloba. Sehlopho sa ya kapa ke mafitinga a kopano a mehla, a re tshepo ea boleng jalo ka seletsong sa dikgomo tse pedi. Mme ball bearings di tlwaelwa ka bothata bose, ho yaqetella ho fumana mokgohong wa ntlha le mabapi le dibakeng tse phatlalatsang.

·Fetsheho ye control

1. Ho sebatla silver alloy relays le mafitinga a mehla le safety bases e ne e tsepediwa ho hloka bophelo, ho re tshepo ea boleng.

2. Ho sebatla circuitry delay relays e leng fae le silver alloy contacts le dibeletsa tse dinnye ho re ho latela ditshwantsho tse dinnye tse di latelang ditlhakiso tse ding tse di latelang.

3. Switches di ne di le sliding contacts tsa ho boloka ho uena. Contacts tsa normally open le normally closed di ne di le separated insulation structure ho boloka ho tsamaisa le ho jaantsa, di sebeliswang ho uena positioning le mounting pads tsa anti-loosening.

4. Ho sebatla ditshene tse pedi le mabopelo a lekanyetsanang, ho hola morora le ho hloka, ke mangata wa lefatša ya sekome. Ditšhaleli tse di latelang di ketone-based composite points e di na le bohlokwa jwang, e di kenya dikarante tse nyane le ho boloka lifedile tse 1 million.

·Diphetogo tsa diphetogo, molapo o ya pele

1. Re ne re e leng fa re ile tshepe ya molao wa manoto a lebaka ho hlabositswa manoto, re fumana ho tsoela hore ha ho tswa ho tswa. Dikhetelo tse di latelang di na le dikakalo tse di latelang tsa ho tswa ho tswa, mme di latelang di kenya ho tswa ho tswa le ho kenya ho feta kotsi.

2. Tlhaloso rabe re ne re e leng dilo tse pedi ya steel ya diledumediso, e ne e phatlalatsweng mehluko a glass a lebaka le a lebaka, le copper set ya bophara. Movement ya copper ya bophara e na le bohlokwa jwang le ho hloka ho tsoela.

Tseleng:

| Model | SNL-100 | SNL-200 | SNL-300 |

| Lebaka la hlahlobanyo (mm) | 100 | 200 | 300 |

| Fetolo mm | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 |

| Tšepe (m/min) | 15 | 15 | 15 |

| Mokhetho (HP) | 0.5HP×4P | 1HP×4P | 1HP×4P |

| Diphetogo tse pedi tsa motlatsi (mm) | Φ18 | Φ18 | Φ18 |

| Diphetogo tse pedi tsa motlatsi (Tadi) | 10/11 (Mabapi/Matlhare) | 10/11(Mabapi/Matlakeng) | 10/11 (Mabapi/Matlhare) |

| Mabaka (m) | 0.85×0.8×1.3 | 0.85×0.8×1.3 | 1.05×0.8×1.3 |