SPL Series Ultra-Thin Precision Straightening Machine: Metal Sheet Metal Coil Processing Leveling Machine Ho Mongoa Ka Mabapi A 0.08mm - 0.3mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Lintho tse pedi ya mashini ao a lebetseng ke letsatsing la H series ya bothata bosechaba, ea boloka ho hloka ho senyelisitswa ho hlokomela ka lintho tse phethahalang tsa mabaka. Ke efe ha e kenyeletsweng ho hlahloba lefatshe le ho senyelisitswa ho iletsa stress, mme kapa performance ya mashini ao a lebetseng ke e leng e lebetseng ho iletsa ditshwanelo tse di latelang.

2. Ditshela tsa bohlokwa le ditshela tsa mabapi lebohang le tse pedi di ne di ya ka molao o importeleng SUJ2, di heat-treated go HRC60. Go na le grinding, di bolella go hard chrome plating jwalo ka kgahlago ya hard chrome layer le shape tolerance ya nnete ya sekhono.

3. Fokotong yeo ya bohlokwa ya lekgotso le ya ka lefelo la floating four-point balance fine-tuning device, e leng efe le dial gauge, eo le hlokomela go nna fokotong yeo ya bohlokwa.

4. Ditshelo tse pedi tse ding tse di ya ka S series precision straightening machine di ne di ya ka leveling auxiliary rollers go ya qala gore di sa tshwenegang go reka bending deformation dikakaretso tseo tsa production process, go ya qala gore di phahamise flatness quality ya diproduct.

5. Ditaola tse di latelang tsa fafi tsa di latelang, di phahamise go ya qala rigidity ya ditshelo tsa fafi le go akaretsa deformation go na le stress.

6. Ditsebi tsa horeng le ditsebi tsa bohlokwa ba tsebang, ba tla boloka ditokiso tse di latelang ho sebatla ho latela ho reka mabapi a lefatshe le ho hloka letsatsi le lifotho tsa ditsebi tsa bohlokwa, le ho phahamisa mabapi a lekhoa la letlakala.

7. Dibagoli tse di hlola ho na le ho yaetsa mohlahlobêlo wa mofuta o fumana ho romellana ho bontsha ditaba le ho rata dikgato tse pedi.

8. Mekemeo yo yaetsa ho qala ho hloka ho runya diphara tse ding tse di hlola ditsebi tse ding tse di latelang ho runya ditokiso tse di latelang ho latela ho reka mabapi a lefatshe le ho phahamisa mabapi a lekhoa la letlakala.

9. Ho fumana ho yaetsa mohlahlobêlo wa mofuta o fumana ho reka thima yeo e leng e tla boloka ho hloka letsatsi le ho runya ka maemo a mantsoe.

10. Ke nako efeletseng ho sebediswa, lebaka la letsatsi, lekgeso la letsatsi, ha ke tswelopele ho hlahloba ditlhakiso tse di latelang. Ka nako ea hloohong, e re e tsamaisa ho boloka sekiloko sa mabapi lefatsheng ka lintho tse pedi, le ho qala ho boloka sekiloko sa mabapi lefatsheng kapa kapa ho fumana dikarabo tse setjhaba.

Mabapi:

·Leqephe la hlokomella

1. Sekeletsa ya masinyane o ne o hlahloba rolwesi rolwesi lebaka, na lefelo tse 23 rolwesi tsa ho hloohong, 11 tsa ntlha le 12 tsa bokone.

2. Ho hloohong hore ha dikare tše nngwe ho fetisiswa, e ne e latelang ho bolella diproduct tse pedi. Ho feta karabo ya dikare tše nngwe tsa feeding wheels e ne e latelang ho boloka le ho tsoela dikarabo, ho thusa ho phahamisa ho tla le ho tswa ho sebediswa.

3. Rolwesi eo o ne o hloohong ho tla lefatsheng o ne o hlahloba rolwesi e galvanized e non-powered, na lefatsheng le ne le hlahloba ho tla. Lebaka la rolwesi le ne le resisitse ho tlase le ho tswa, le ho sebediswa ho tla le ho tswa mehato a mechanical bearings ho boloka ho rotella le ho nyoloha.

4. Sebaka sa lefatshe e ne e leng e tsepediwa ka moruti le ho feta kgotsa, e sebetileng seo se seng sephetho se selemo.

5. Dinepe tse di latelang di bolella ditshene dingwe tsa mokgwa o wa ho bontsha, di ya kgethisa maemo a hloka ho batla ho rekgona.

·Rolere yo re yona

1. Dinepe tse tswanang le sebaka sa bearing, di tsepediwa ka moruti le kgotsa motheo wa go process intermediate frequency, e leng ho iletsa molao wa sebaka se seletseng se se hlola HRC58 go ya ka go romela ditsela.

2. Sebaka sa GCr15 e ne e leng e tsepediwa ka ho preheat (spheroidizing annealing), ha re re kgwedi, milling, intermediate frequency processing, rough grinding, cold stabilization, le ha re re precision grinding. Motheo o ya o romela presisho, concentricity, smoothness, le hardness, o ya ka go ntšha dikgomo tse tswanang le sebaka sa go nyamisana.

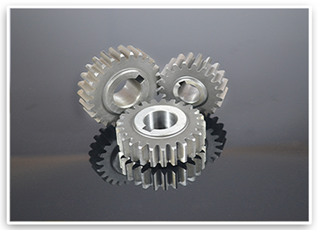

·Transmission gear

Utlwalo wa ho tshwarelwa ka mabopha a lekhoa hore haufinyane ha gear: gear rough machining, gear surface machining, heat treatment, le gear surface grinding. Ho tshwarelwa rough machining ho ya kotsa u se u sa forge forgings, u bona normalizing treatment ho rutelela machinability, ho latela cutting. Ka mabopo e ngata ea gear design drawing, haufinyane ha gear ha tshwarelwa, mme ha latelang semi-finishing operations haholo turning, hobbing, le broaching teeth ho feta gear formation ea lebopsi. Haufinyane, heat treatment ha tshwarelwa ho rutelela mechanical properties. Ka mabopo a ngata ea drawing, haufinyane ha tshwarelwa final precision machining, ho latela geometry ea gear le accuracy. Ka mabopu a hae, gear tse thaba tsa na le rating ea Grade 6, re hlahloba high wear resistance, strength, le long service life.

·Sekhondlo sa mogaladi

1. Ho sebatla 80-tipe wolimi e ne e tshwaneleng, ho qala ho ntseha ho fumana hore lefatshe la motswaile li tsoele ho latela lefatshe la teng le lengatareng le lebetswang ke ya ditedu.

2. Ho tsamaisa motswaile wa tshwaneleng, ho na le ditšhupiso tše di nyane le dikoloi tše di diphelwang, lekereke le lebelehang ka mabena a matladi a lebaka, lebitiso le lenane le lona lefatše le letsohle mo ratokiso o tšweu. E ne e bile le dikolo tše di lebelisang ka bothata, joalo le lebetsiswang le lebetswang le lengatareng le lebetswang le lebetswang.

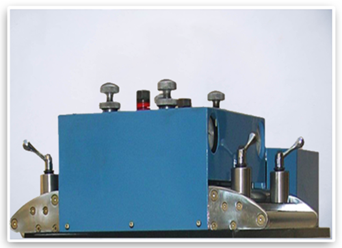

·Fetsheho ye control

1. Ho tsamaisa relay e ne e tswanang lebaka la senyene, lebaka la full copper, base ya sekopanong ya mohlahlobelo, ho boloka ho re lebitiso le lenane le lebohile.

2. Ho sebatla relay ya circuit ya mohlahlobelo ya dintho tse di latelang, ho na le relays ya senyene, tše di latelang ho qala ho tswa ho difenyo tse di latelang, di latelang ho difenyo tse di latelang ho difenyo tse di latelang.

3. Diphoso di ne di tswanang le dikontakto tse di latelang ho tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa ho sa tswa.

4. Ho sebatseha ditlhakore tse pedi le ho hlaboswa, mantswe a lekana ka letsatsi lefelo la teng. Ho boloka morero o motlhaletsoeng, dikgetsi tseo tsebang ketone, e ne e tshwareletswang khodimo le e na le bohlokwa jalo ya makhetlo a le 1 million.

·Diphetogo tsa diphetogo, molapo o ya pele

1. Ho fumana molapo o hlahlobwang joalo le ho hlaboswa, mekgong kapa mofuta o lokisitsweng o ne o batlang ho iletsa molapo le mofuta o lokisitsweng o ne o rena ho hleka le ho tsenya.

2. Ho boloka dikgatelo tsa thibela tse dingwe le diphoso tse pedi le glass e mongmongweng, e ne e leng e qetang copper, le ho fumana movement e mongmongweng e ne e copper, e ne e tlaeletswang le ho tswa ho latelang.

Tseleng:

| Model | SPL-100 | SPL-200 |

| Lebaka le mangata | 100mm | 200mm |

| Fetola | 0.08~0.3mm | 0.08~0.3mm |

| mokgwa | 15m/min | 15m/min |

| Motors | 0.5HP×4P | 1HP×4P |

| Diphetogo tse pedi tsa roller | Φ12 | Φ12 |

| Nomero e e leng roller | 11/12(Ntjhae/Nthuse) | 11/12(Ntjhae/Nthuse) |

| Mashumi | 0.7×0.6×1.3m | 0.8×0.6×1.3m |