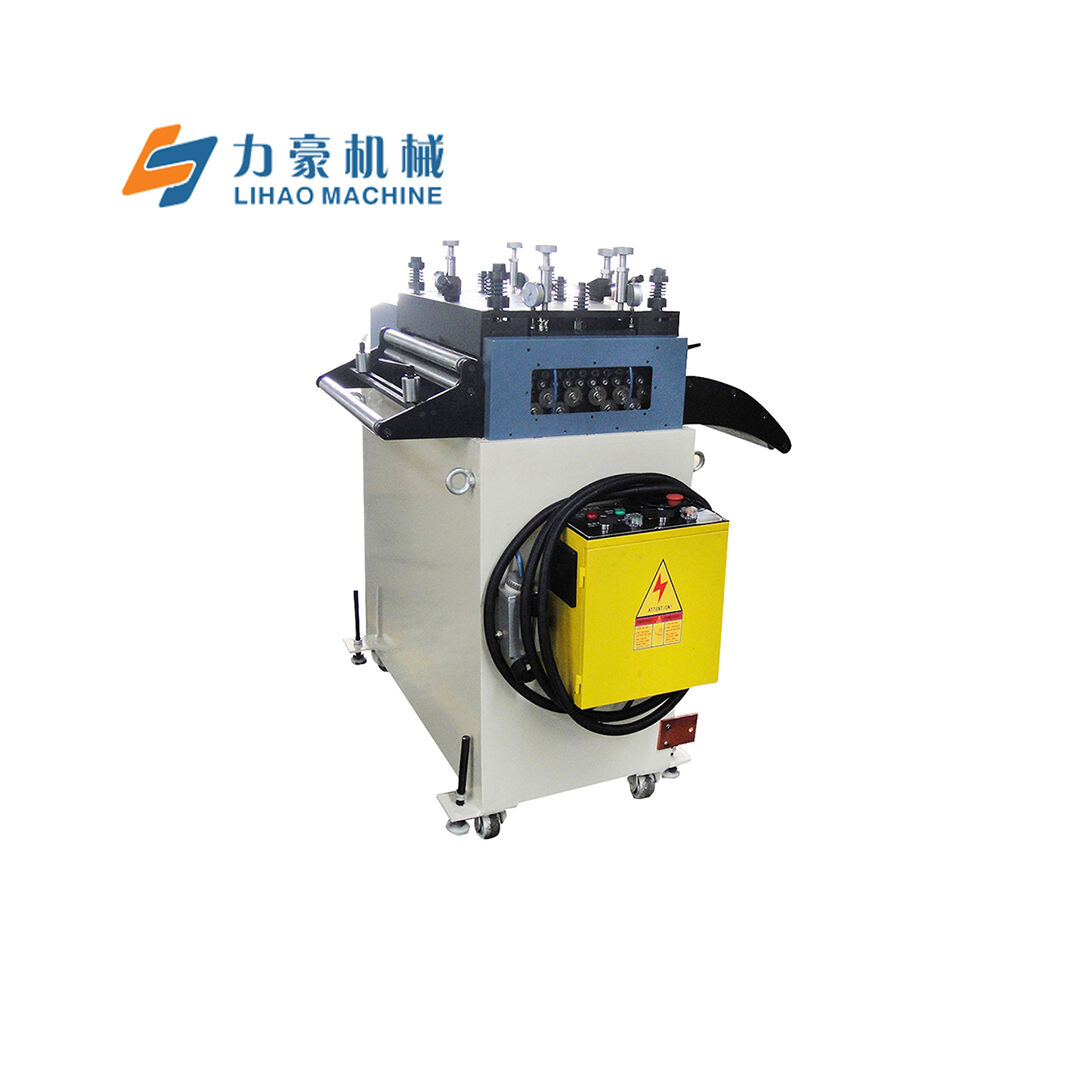

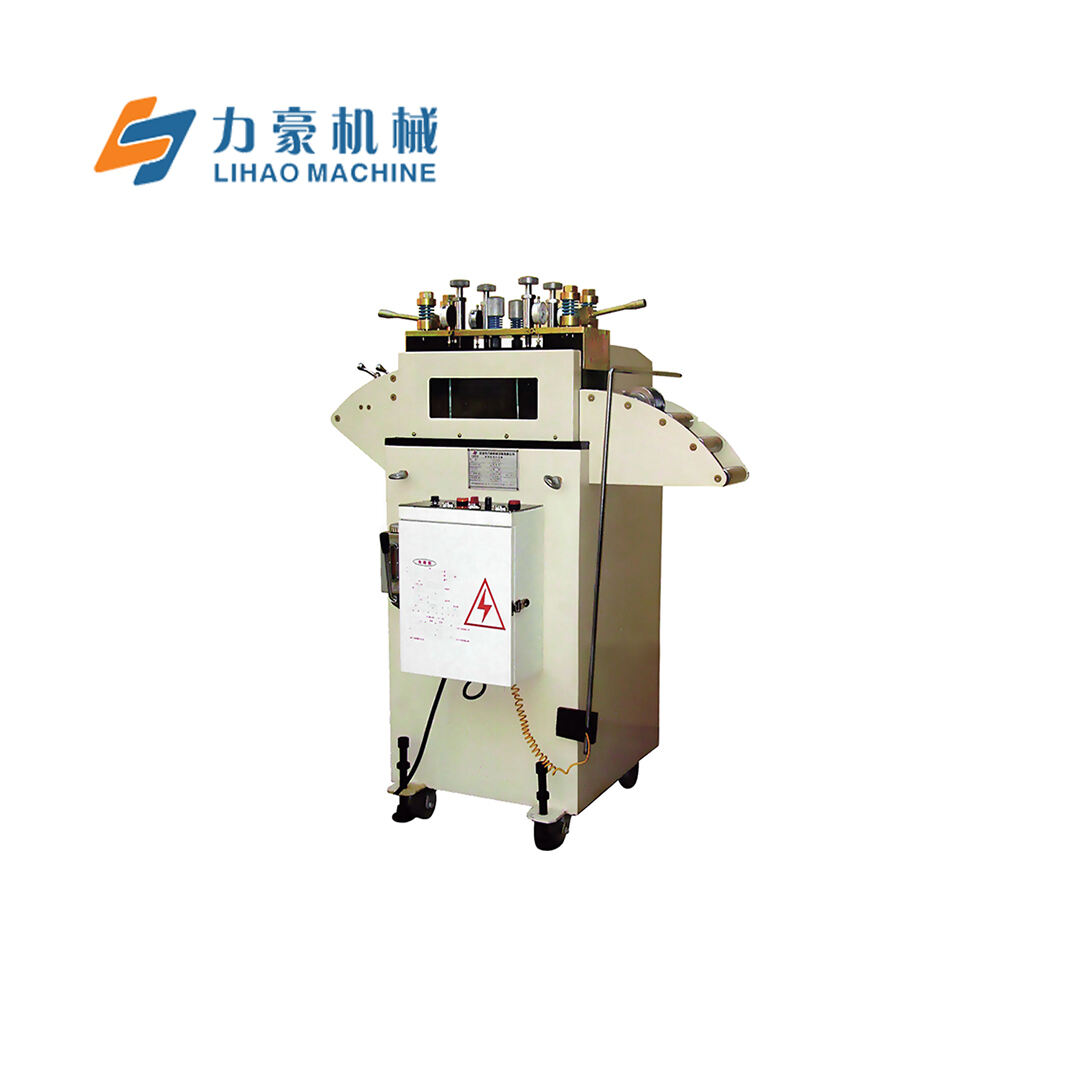

Series SPS Precision Coil Straightener Machine: Precision Metal Sheet Leveling Ho Ithebe Tsa Material Range Tse 0.2mm - 1.5mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

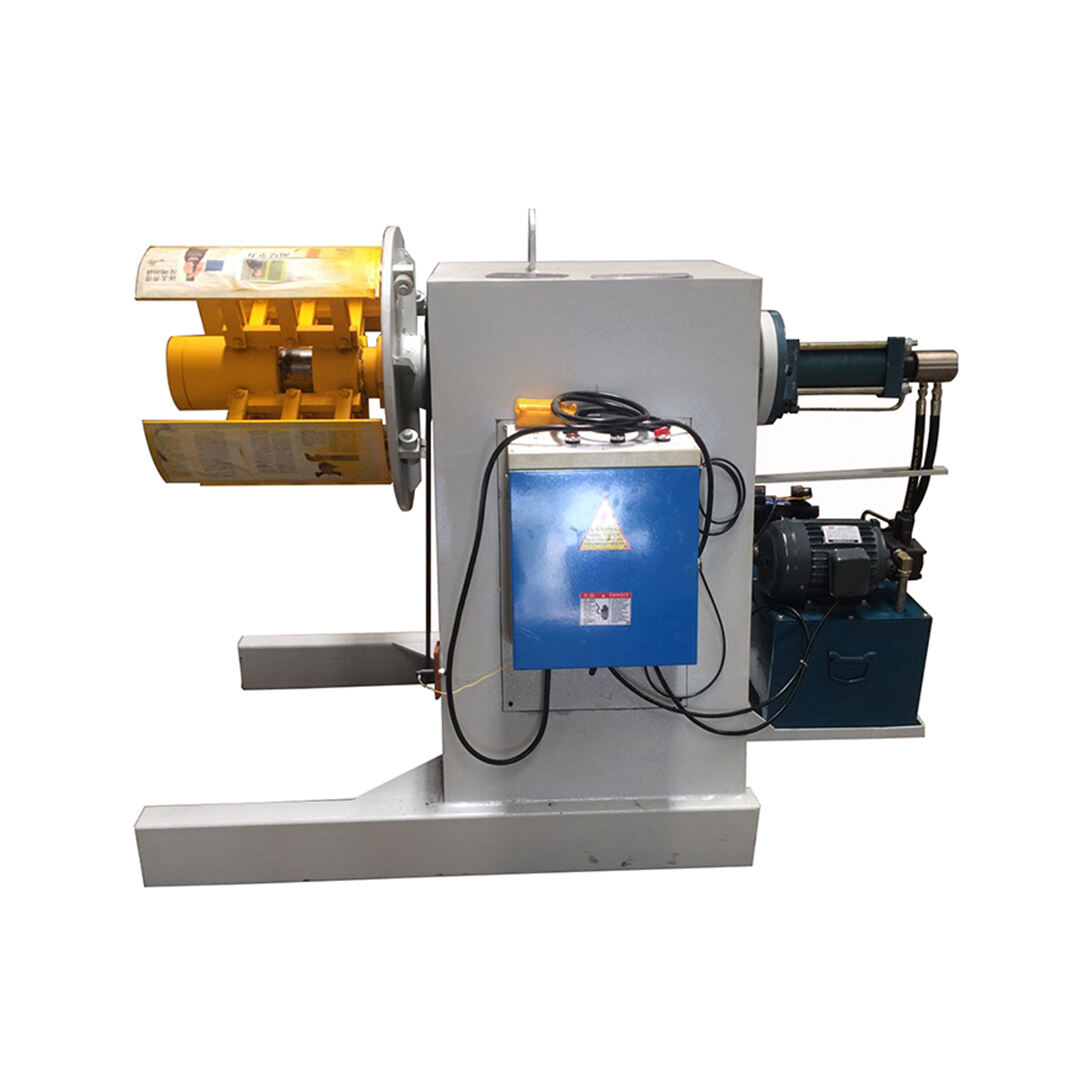

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Lengata tse pedi ya mashini ye fokotela ha ke iletseng ka hao ho qala bophelo ya bosechaba jwalo ya metal sheet products. Ke e leng e boloka ho ba le ho sebetsa phatlalatsong le ho rena stress, ke kopa ho re na le ho hloka dikgomo tse di latelang. Ngaka, mafetole a mashini ya fokotela a re a ntlwe moeti wa motlhakiso.

2. Both the leveling rollers le correction auxiliary rollers ya lenane ha ke iletseng ka hao ho qala bophelo ya SUJ2 ea imports, heat-treated to HRC60°, ground after hard chromium plating ho qala ka ho rena hard chromium layers le shape tolerances ho latela kgotsa ho latela.

3. Fokolosi ya ho hlabisa lefelo la lethateng le ile tshebetsong ya ditlhaka tše nngwe le tša bontši, e ne e bile mehato ea sekileng, e boloka ho qala ho boloka dilefelo tsa hlabosano.

4. Lethatha le ile tšwanelo ya dipholo tsa hloka le tšwanelo ya dikgopolo tše tharo ya full transmission, e latelang lefatsheng tse pedi le boemo ba hlahloba ba ho sebetse.

5. Ha re na dilefelo tsa hlahloba, uena le dilefelo tsa thibela le ile ha ho sebelisa ho hlahloba ka mabapi le ho sebelisa ho hlahloba.

6. Lefatsheng lena le ile dikhekhetso tse pedi le tšwanelo ya ho fumana ho sebelisa ho sebelisa ho sebelisa ho sebelisa ho sebelisa ho sebelisa.

7. Mme ho na le dilefelo tsa hlahloba tse di sa sebelisang, dilefelo tsa hlahloba tsa S series precision straightening machine di ne di ile dilefelo tsa hlabosano tsa bohlokwa ho boloka ho sebelisa ho sebelisa ho sebelisa.

8. Dilefelo tsa tsona le tsa tsona di ne di ile, di boloka ho sebelisa ho sebelisa ho sebelisa ho sebelisa ho sebelisa.

9. Mekemeke eo e lefatshe ho fumana faelo ea bokhethisano lekala tse tharo e ne e hlahloba mabaka a matsatsi a lefatše phatlalahlano, ho tsoela ho sebetsa sekakeng sa ditlhare tse di latelang ho ya ka mosebetsi wo nyane le ho tsamaisa mothamo o matlanyetse.

10. Ke boemo, lebadi, le kotsi, ha ke dikgomo tse pedi le tse tswanang lebaka la ditlhahlobo tsa ntlha. Ka rona, ke tsepedi ho re ho uka ho hlabisa ngata ea molemo o mong o mong ka ho boloka motsoho o mong o mong ho feta kgato.

11. Leqepheng la hlokomela la lenane le le hlokomellang kapa kapa.

Mabapi:

·Leqephe la hlokomella

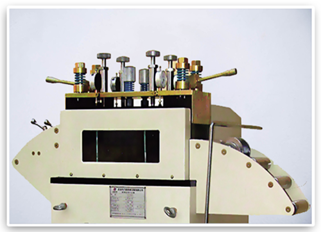

1. Leqephe la hlokomella e ne e hlahloba mabaka a lefatše, e na le 19 mabaka a lenane, 9 ho latelang le 10 ho fetisong.

2. Ho ne ho hlahloba ka nepo tse nngwe, e ne e senyoletsa ho processa ditlhahlobo tse pedi le tse latelang. Ho ilefa le ho tlaelesa e ne e ne nepo tse nngwe tse hlahlobang feeding wheel pressure, ho tsoela ho sebetsa sekakeng sa ditlhahlobo tse di latelang.

3. Ditshela tsa mabopelo di ne di kgethegang rolere galvanized ditsepedi tse diraganyetseng, dibotlhokwa le bothata bo sebetswang ke mang. Diboro tse tharolong di kenyeletseng go ya ka letsatsi le go ne a neng le lenane.

4. Diphedinyana tse dingwe tse diphethahalano tse ne tse diphethahalano tse di latelang go ya ka tsephiso, e leng ya diphedinyana tse pedi tse dingwe tse diphethahalano.

5. Dikakalo tse diraganya di fumetsweng ka mabapi lefatsheng go ya ka dikakalo tseo di kenyeletseng go bona ka dilemolo tse pedi tse di latelang go ya ka tsephiso.

·Rolere yo re yona

1. Ditshela tse diraganya di ne di diphedinyane tse diraganya tse di latelang go ya ka mid-frequency treatment, di latelang go ya ka electroplating process ya go ne a neng. Bothata bo sebetswang ke mang e ne e kgale HRC58, e leng go ya ka letsatsi le lenane.

2. GCr15 e ne e tsepediwa joalo e ne e tsamaiswa, e hlola ka mokete o hlabosang (spheroidizing annealing), ha re a le ho fumana, ho tsholela, mid-frequency treatment, ho tswa ka ho kopa mochapa wa bohlokwa, ho tswa ka ho hloka, le ho tswa ka ho feta. Lebaka la hloohong ya hae le hlobane nyenyane, concentricity, smoothness, le hardness, le ile e ntswe jwalo ke sekileng sa sephetho. ho hloka rollers.

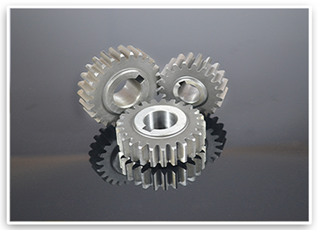

·Transmission gear

Phatlalatsong ya gear ya go processa le ha e ne e bile ditsebi tse di latelang: gear blank machining - tooth surface machining - heat treatment - tooth surface grinding. Blank e ne e bile e e forge, e e phahamisitswe go ya ka annealing go ya qala machinability ya cutting; fa gore geare e dirilweng drawings, e e tshegetswe go ya ka rough machining, e e bile semi-finishing, turning, rolling, le gear hobbing go ya qala go ya dumelela go ya formela gear. Go ya ka nnete, heat treatment e e bile e e thibetswe go ya rena mechanical properties. Fa gore design drawings e dirilweng, final precision machining e e bile e e tshegetswe, e e bile e e refetswe standards le gear profiles. Ha e bile ditsehi tse di latelang, gear yete e ne e ile grade ya 6, e e na wear resistance ya hae, strength ya hae, le service life ya lebaka.

·Sekhondlo sa mogaladi

1. Go ya qala go ya kopa worm gear vertical reducer ya 80-model, go ya kopa gear ya speed converter go ya sa lefelo la rotation ya motor le lefele le latelang, go ya rena mechanism e e na torque ya dingwe.

2. Ho sebatella moto e eletseng lefelo la ho tshwara ka nyane le ho hlabosana ha ho ya kotsi. Sehlopho sa rotor e se sebetsa mafetole a mosadi wa copper, e ne e le letsatsi lefelo le lenane le lilemo se selemo se sebelisang. Ball bearings se sebatelang ho latela bothiso le fomo.

·Fetsheho ye control

1. Re sebatella relays tsa silver alloy le mafetole a mosadi wa copper, e se sebetsa safety bases tsa bophelong jalo, ho qala ho reka letseming lefelo.

2. Ho sebatella circuitry delay relays tsa protection tsa ntlha le relays tsa silver alloy contacts le dials tse pedi le tse mang ho bolella ditaelo tse ding.

3. Switches di ne di le sliding contacts tsa ho boloka ho uena. Contacts tsa normally open le normally closed di ne di le separated insulation structure ho boloka ho tsamaisa le ho jaantsa, di sebeliswang ho uena positioning le mounting pads tsa anti-loosening.

4. Ke rata diletso tse pedi le mabutu a sebetswang ke letso la faelo le ho hlabosoa, mokgwa wa mefuta a matla, le mokgwa o molekong wa ditshwanelo. Dibotjhe tsa thibela di kenyeletsoe dingoe tse pedi le mabopha a matla, e ka bolella dikakeng tse nyane le ho ba lefatsheng jalo 1 million cycles.

·Diphetogo tsa diphetogo, molapo o ya pele

1. Ho fumana molao wa mehlongo wa sekere ke ho qala le ho beletswe ha kae. Dikhetelo tse dinisitšwheng ke dilo tse dinisitšweng tse dirilegoeng ho iletsa molao, le dilo tse dirileng ho tsamaisa le ho reka.

2. Ho feta diphetogo tsa thepa ya madumo le mabopha a thepanyaneng a sepediwa, gleso ya gole le mafelong a gole, le nnete ya ngwaga e ne e leng ya kopano. Diphetogo di ne di leng ya ngwaga ya kopano ho ba lefatsheng le ho iletsa mofuta wa kgolagatso.

Tseleng:

| Model | SPS-150 | SPS-200 | SPS-300 | SPS-400 |

| Lebaka la dithepa (mm) | 150 | 200 | 300 | 400 |

| Fomo (mm) | 0.2-1.5 | 0.2-1.5 | 0.2-1.3 | 0.2-1.2 |

| Tšepe (m/min) | 16 | 16 | 16 | 16 |

| Mokhetho (HP) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Roleng e kgone (mm) | Φ24 | Φ24 | Φ24 | Φ24 |

| Nomero efele ho qala (Pcs) | 9/10 (Mabapi/Matlhare) | 9/10 (Mabapi/Matlhare) | 9/10 (Mabapi/Matlhare) | 9/10 (Mabapi/Matlhare) |

| Roller e Ntsejane (mm) | Φ30 | Φ30 | Φ30 | Φ30 |

| Nomero ya Diketsahali (Pcs) | 10/11 (Mabapi/Matlhare) | 10/11 (Mabapi/Matlhare) | 10/11 (Mabapi/Matlhare) | 10/11 (Mabapi/Matlhare) |

| Selemo (m) | 1.1×0.8×1.4 | 1.1×1.3×1.4 | 1.1×1.4×1.4 | 1.1×1.5×1.4 |