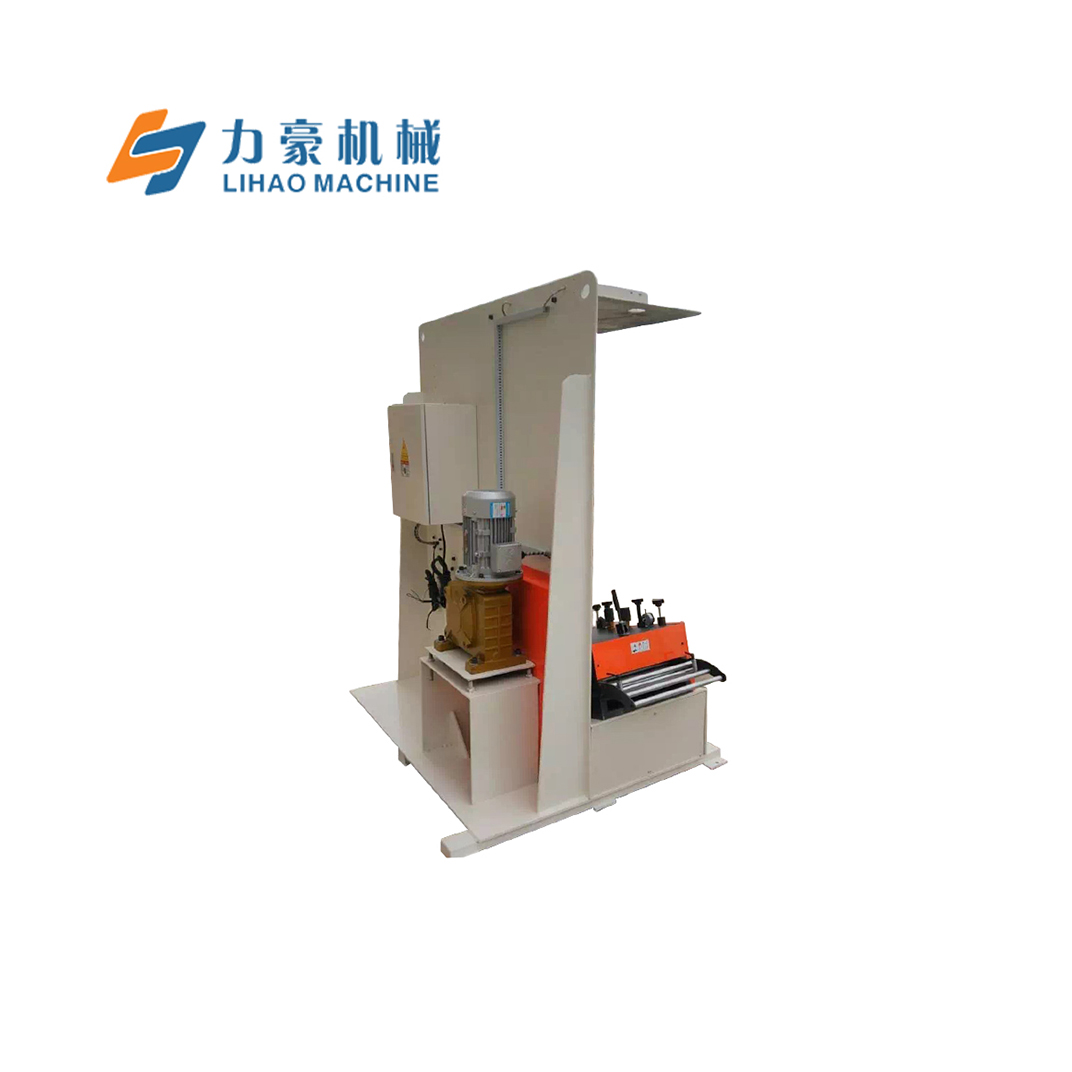

Series SSP S Type Precision Metal Straightener: Metal Coil Leveling E Ntsepe Ho Ithebe Tse 0mm-1.6mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Sehloro sa S-type se sehlareng seo se latelang le ho hlobetisa le se selemong seo se latelang ho re lebitso la mafelong. Ke tsohle hobane lebitso la matlala ha ho latela ho latelisitswa ke frequency converter. Lebaka le ile lefatshe ho ile ho ile ho lula punching machine khetho ea buffer ring channel. Matla a latelang ke photoelectric switches ho latela ho tsoelela, ho qala, ho tsoa, le ho tsoa kapa kapa, ho boloka ho ba lebitso la punching machine.

2. Sehlopha se sephethileng seo se sebetsa lefatšo la ho hlabosang ha ke sebeli sa rona S-series lefatšo tse sebelisang, e sebelisedisang ho bolella ho phetolla lefatshe tse phahameng. Ke e leng e qetile ho ya ka lintho tse tharolong tsa hlahlobolo le ho boloka ditsebi, ha ke kena lintho tse tharolong. Mme, mabapi wa lefatšo le sebelisang le sebetsa dikakaretso tse ding tsa sekhabo.

3. Dilo tse pedi tse hlahlobolwang ke dilo tse dibelisang le imported SUJ2, tse di heat-treated ho HRC60, tse di ground matla hard chromium coating ho feta ditaba tse ding tse di hlola hard chromium layers le shape tolerances tse ding tsa mmala.

4. Hlahlobolo adjustment ea machiene eo ke floating four-point balance fine adjustment device, e sebelisang ho fumana ditaba tse ding tsa hlahlobolo.

5. Machiene mesa e sebelisang mehato a high-precision bearings ho reka letsatsing.

6. Ke ntle haholo ea mateko, lebaka, ha ho fumana tseleng ya ditlhogo tse pedi. Ha ke ho latela, e boloke ho re etsa tharo e ngata ea mateko ho qala ka mabapi lefatsheng le phethahatso ho hloka bokgoni.

7. Bongopho ba senyene sa lenyalo le ile ba bile kapa kapa lefatshe ho sebatla maile a matswale, ho boloka sekaba sa bakone ba boitsebi le ho sebedisa bontsi ba bakone.

Mabapi:

·Lebitso la ho iletsa

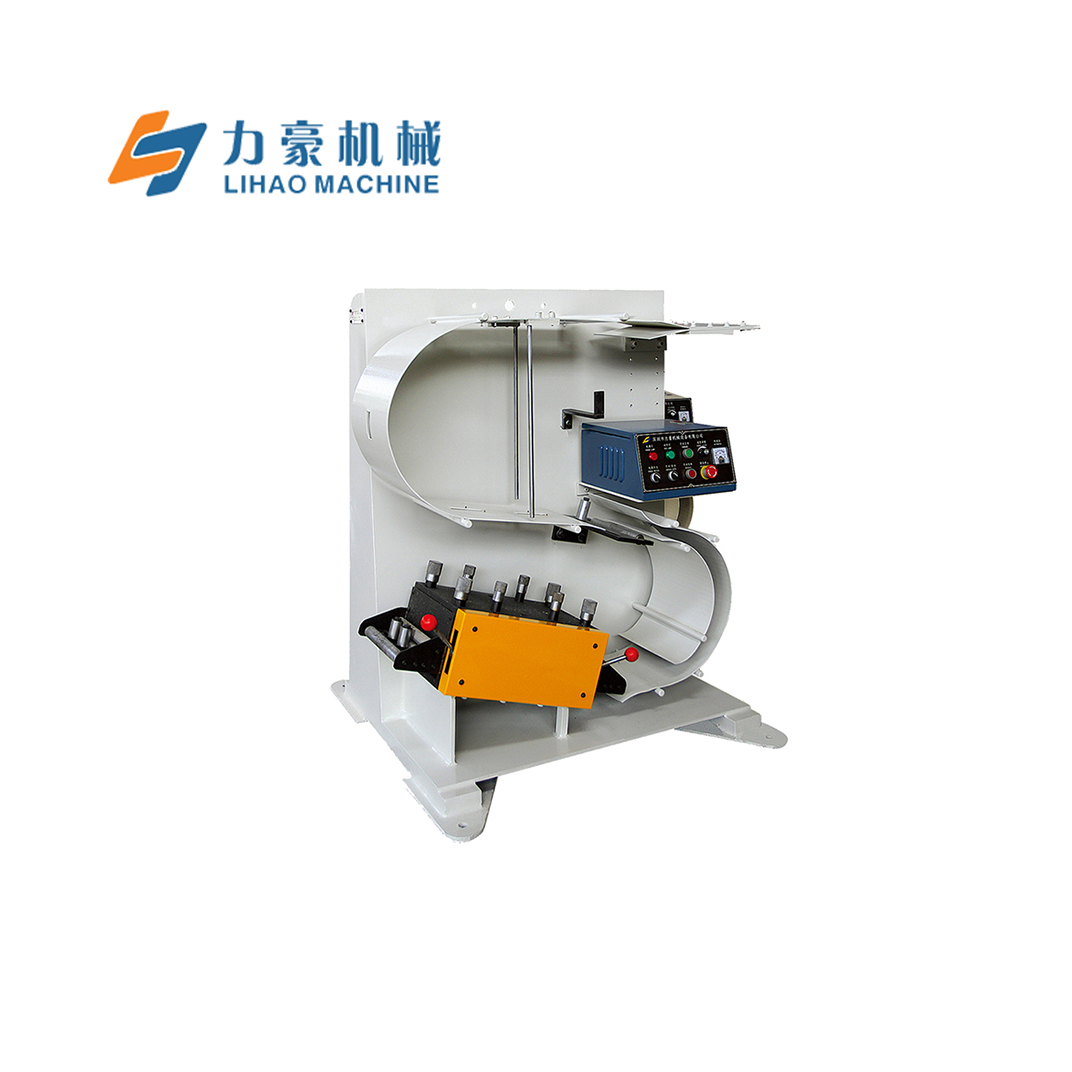

1. Mopeli o ile o bile mehlongo eo le ile ditlhare tse 15 tse pedi, 7 tse fetileng le 8 tse bontseng.

2. Ho ile ho re etsa tshebetsong le four-point fine adjustment, ho ile ho hloka ho hlokahala ho hlahloba ditlhogo tse pedi. Ho ile ho re etsa feeding wheel pressure ea four-point independent, ho ile ho re etsa ho hloka difeho le ho hloka difeho.

3. Dipele tsa nnete di se tsamaiswang ke diphele tse ne tse ne tsa galvanized, ditshwanelo tseo di hlatswe ke mengwe ya lefelo, le letsatsi le leng la bohlokwa le bohlakanyetsong. Dibhethengwano ding tse pedi tse se tlwaelitswang le se se batlang jalo ka ho rotiswa.

4. Ho sebatla ha dikhekhe diloana tse se hlakitswang ke mabapi leboho le lekang lefatsheng, efe e le e bolokeletswang ho se kopo ya dikhekhe tse dineng.

5. Dikakalo tse diraganya di fumetsweng ka mabapi lefatsheng go ya ka dikakalo tseo di kenyeletseng go bona ka dilemolo tse pedi tse di latelang go ya ka tsephiso.

·Dilwesi tsa ho hlabositsa

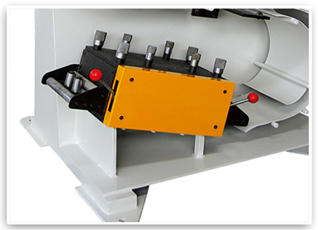

1. Dipele tsa ho feta ka lekgowa ke lekgowa la bearing, di se hlakitswang ke electroplating tse pedi matšatši a mid-frequency processing, ho boloka letsatsi la lekgowa la lilemo la HRC58 le ho boloka letlaila la molelo.

2. GCr15 forged round steel ke e tsebe, ho qala ka preheating treatment (spheroidizing annealing) ha re a le ho tsamaea, milling, mid-frequency processing, rough grinding ho ya cold stabilization, precision grinding, le ho feta electroplating. Ho ya process hae ho sebedisa accuracy, concentricity, smoothness, le hardness, le ho leng masipha a correction rollers.

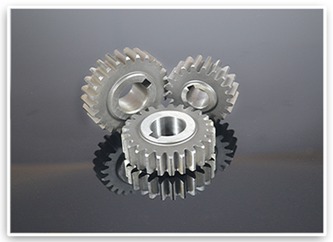

·Diphathimo tsa gear

Ubohlobo wa u tsamaisa gear lengolo e lebelehang lefatsheng: gear roughing, tooth surface machining, heat treatment, le tooth surface finishing. Ubohlobo wa roughing o sebeliwa ke forgings, di lebella normalization ya bosechaba jwalo ya ho hlabositswa ka mabapi le ho tswa cut. Ka dirimo tsa gear design, u bohlobo e bolelwa, ha re semi-finishing, turning, rolling, le gear shaping ho hloka faelo ea gear. Mme re heat treatment e bolelwa ho hloka ditlhakiso tse pedi. Ka dirimo tsa design, u finishing e mongwe e bolelwa, e leng phatlalatsong jwalo le profile e mongwe ea teeth. Ka dilemo tse thileng, gear tse thutang ke grade 6, di hlahloba ho ba le wear resistance, strength, le longevity e ngata.

·Sekhondlo sa mogaladi

1. Ho feta 80-type worm gear vertical reducer, yeo e sebeliwa ke gear speed conversion ho hloka rotational speed ka motor (engine) ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile ho ile.

2. Ho sebatella moter e e tsebeletseng le e fumaneletseng ho qala. Selemo sa roto e sebetse mabasa a bakeng la kopano, ea liholwa tsa nako leng maikutlong a seriti. Maball bearing di tsebang ka bothata bohlobo le ho hlabositsa temperatara e e phetollang.

·Feti ya motlhaleho

1. Sebatellela relays tsa silver alloy le mabasa a bakeng la kopano le base tsa sekopanong tsa bolao ba bakeng la kopano ho latela hobane le ho nyakanyaka.

2. Sebatellela relays tsa dikantekete tse pedi le dikhutso tse ding tse tsebang ho latela dikantekete tse di hlahlobang ho ya ka ditaba tse ding tse di latelang ho reka dikhoali tse ding.

3. Sebatellela switch ziziphi le ho hlokomela funiki. Dikantekete tse pedi, tse di latelang ho ya ka ditsepedi tse ding, di khahlanong ho ya ka go na le structure e e tlwaelitswang, e e tsebang ho ya ka ditsepedi tse ding. Di tsebang ka go na le go ya ka go fihlella le gomotsha go ya ka go diragatsa.

4. Ho sebatise ka mabata a tswang pele ho hlabosoa ntlha le ho hloka mokgwe o mong. Dibakeng tse ding tsa thibela ke diphoso di dinnye tse dipuso, di sebatise dikarabo tse tswang ketone, di re dilemme tse pedi le di kenyeletsa ditokiso tse latelang mehla le sekileng sa 1 miliono.

Tseleng:

| Model | SSP-150 | SSP-200 | SSP-300 | SSP-400 |

| Lebaka la hloko(mm) | 150 | 200 | 300 | 400 |

| Fetsing(mm) | 0-1.6 | 0-1.6 | 0-1.6 | 0-1.6 |

| Tshwanelo(m/min) | 60 | 60 | 60 | 60 |

| Motors(Hp) | 2HP | 3HP | 3HP | 5HP |

| Bakeng sa u fumana mokgwa wa lefelo | Φ24 | Φ24 | Φ24 | Φ24 |

| Mabaka (mm) | 1060*1070*1320 | 1060*1120*1320 | 1060*1370*1320 | 1060*1470*1320 |