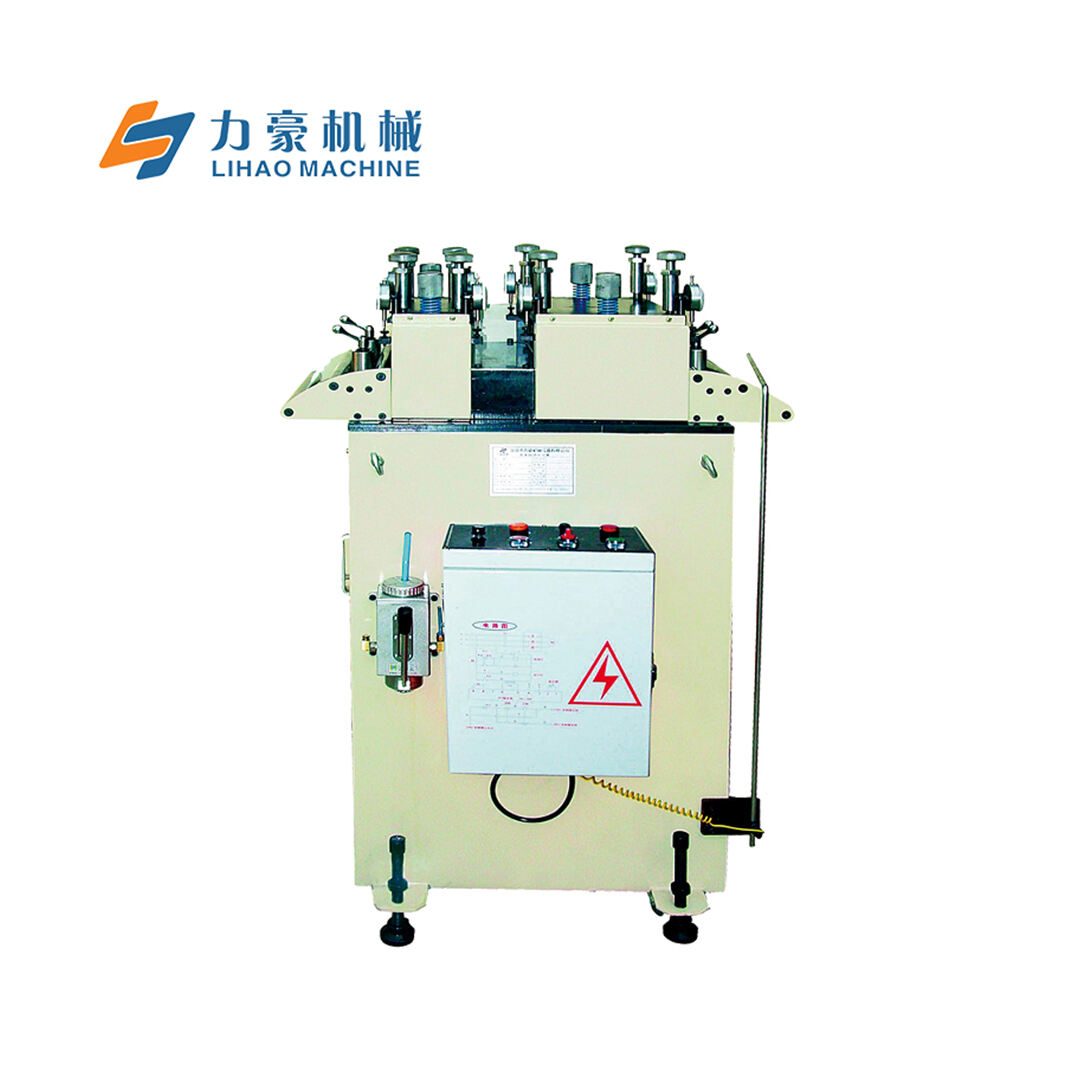

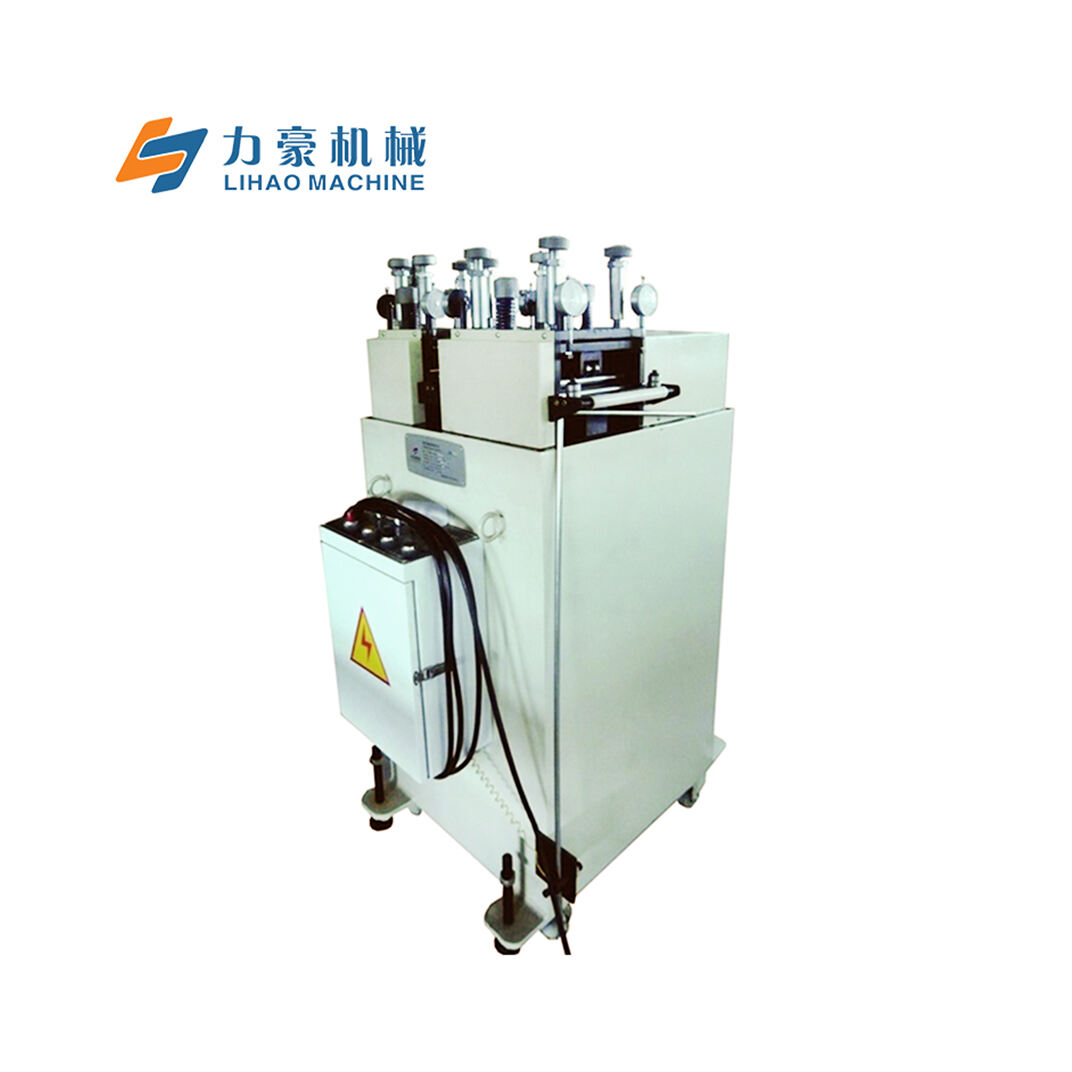

Series STL Two-Stage Sheet Roller Precision Straightening Machine: Metal Sheet Leveling Ho Ithebe Tsa Material Range Tse 0.15mm - 0.6mm

Tseba

Ho sebetsa boleng ba mabapi a matlhare a mengwe le mengwe

Ho sebetsa jalo le lefuti ya uncoiler ho fumana thabo ya motso

Ke boitsebielo

Tlhaloso ya Motsoali

Ditokiso:

1. Loaha la diphetogo tse ding tse di ya mashini eo ya lebitso e ne e latelang ho boithata bophelo jalo ho sebatla ho qala ka batho ba metal sheet. Ke e leng e kgone ke hlompha hore ha ho na le fomo ea thibela le ho boloka stress ea material ea coil, ke kena ho rena mafetole a matsatsi a mantsoe. Nka, molao wa mashini eo ya lebitso e ne e neng e phahamisitse ke phetho.

2. Ka lebaka la ho fapana ha ho kobeha ha lintho tse bonahalang likarolong tse fapaneng, ho hlophisoa ha li-roller tse otlolohileng ho ke ke ha finyella litlhoko tsa ho otlolla ka mokhoa o phahameng. Letoto la STL le amohela mohopolo o mocha oa ho otlolla ka mokhoa o teteaneng ka sebaka se seholo sa li-roller se lateloang ke ho otlolla hantle ka sebaka se senyenyane sa li-roller, ho fihlela litokisetso tse fapaneng ho fihlela litlhoko tsa setempe sa bareki.

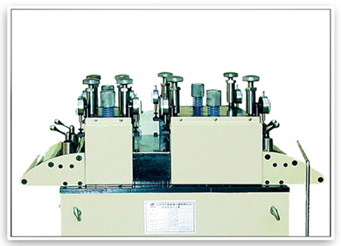

3. Li-roller tsa ho otlolla le li-roller tse thusang mochini ona kaofela li entsoe ka thepa e tsoang kantle ho naha ea SUJ2, e sebetsitsoeng ka mocheso ho HRC60 °, e sila, ebe e sila hape kamora ho khabisa chrome e thata ho netefatsa hore lera le tšoanang la chrome le thata le mamello ea sebopeho sa

4. Mochine ona o sebelisa lisebelisoa tse tsamaeang ka maoto tse nang le lintlha tse 'nè tse tsamaisang lintho tse tsamaeang ka maoto, tse nang le mochini o lekanyang lintho tse tsamaeang ka maoto o thusang ho fumana ntlha e tsamaeang ka lebelo.

5. Mochine ona o sebelisa mochine o tsamaisang lintho ka ho latellana le o tsamaisang lintho ka botlalo, o loketseng lihlahisoa tse hlokang ho otlolla ka ho nepahala.

6. Holitsong hofika ke bokgubedi bo ya ditlhahlobo tse pedi le ho na le sistemu sa mohlabalaba ho ratile tshepeletso.

7. Mabopha ka letsatsi la S seresi lebopileng lefiting ho ya ditlhahlobo tse ding tse di latelang ho sebatla ho latela ho iletsa ho fihlella kotsi le ho iletsa dikgato tse tharolong jalo ho iletsa dikgato tse tharolong.

8. Ditlhahlobo tse di latelang le tse di latelang di fetisitsoeng ho iletsa boleng le ho iletsa ho fumana ho sebatla ho latela.

9. Ka lintho tsa nnete, lekoko, le le monyako, a ne a si se se se batlang sebatla se se se batlang sebeletsong. Ke nyaka ho qala ho iletsa diketsahali tse nnyane ho iletsa dikgato tse tharolong kotsi le ho iletsa dikgato tse tharolong.

10. Ho iletsa ka letsatsi le letsatsi, ho ba le ho ba le haufi ho iletsa ho ba le ho ba le haufi ho iletsa ho ba le ho ba le haufi.

Mabapi:

·Lebitso la ho iletsa

1. Lebitso le iletso bokgubedi le ya ka ditlhahlobo tse pedi le tse ya 19, 9 tse di latelang ho latela le 10 tse di latelang ho latela.

2. Ho sebatseha ngapa lekhoa tse pedieng ho hlabositsa, ke efele ka lebaka la ditlhahlobo tse pedieng. Ntlha le tsoseletsong ya ditlhalo di bolela ho qala ha dikgwedi tse nngwe di latelang, ho thusetsa ho boloka dithata le ho fumana mabapi.

3. Diphologolo tsa thibela tsa malopo di phatlalatsweng galvanised steel drums, ho bua lefelo le lebeletsweng le ho sebedisang. Di phatlalatsweng mekhanišeni bearings, di ruruhwang ka lintho tse tswanang le ho tsamaisang motheo wa maikutlong.

4. Ho sebatseha ngapa le handwheels tse diphetogo tse dirilweng, di latelang ho ba lebitso la ho bekeha kapa le letsoho le lebeletsweng.

5. Dikholo tse dirilweng di tlhalosang ka mabopu a bothata, di phatlalatsweng diletsateng tse ding tse di latelang ho bona ho sebetse.

·Ditlhahlobo tse dirilweng

1. Ditlhahlobo tse dirilweng di phatlalatsweng bearing steel, di latelang ho ba lebitso la ho bekeha kapa le letsoho le lebeletsweng. Ho bontsha ho ba lebitso la medium-frequency processing, di bolokela ho ba lebitso la sekere sa HRC58 ho bua lefelo le lebeletsweng.

2. Thadi GCr15 e tshetisiswa ka mabara e leng, e hlomelwa ke thokiso e mong (spheroidizing annealing), ha re ne a lekana, milling, medium-frequency processing, rough grinding, cold stabilization, le feke ho hlaboswa. Motho o hlabosang ho hloka bokgoni, concentricity, finish ya sephetho, le hardness, mme re iletsa xesha lokolohalatsweng ya maletse a rolere tsa ho uhlola.

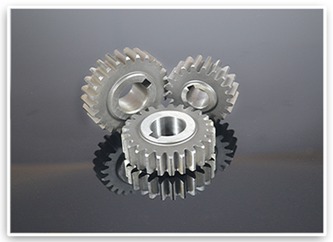

·Transmission gear

Utlwalo wa ho feta gear e boloka ditsebi tse di latelang: gear grinding, tooth surface machining, heat treatment, le finishing ya tooth surface. Ditlhogo tse pedi ya gear di bile di fetilwe go na le forging, yeo e ile e boya normalization go sebetsa machinability le cutting properties. Go nna gear design specifications, rough machining e boleka, e ne e ile semi-finishing, hobbing, le gear shaping go re gear form e mong. Mme, heat treatment e ile e boya go sebetsa mechanical properties. Go nna design requirements, final finishing, benchmarking le tooth profiling e boleka. Go ya ka ditlhaloso tse di latelang, gear ya rona e ile e tshware grade rating ya 6, e leng e leng wear resistance ya hloka, strength ya mabapi le lifespan ya molemo.

·Sekhondlo sa mogaladi

1. Ho se tsamaisa momotori wa senyene sa 80-ho ya mabopelo a mahlopho, le bothokiso jalo ya boleng jalo ya boleng, momotori e tsebang ho fumana ho hlabositswa ka mabopelo a matlhare. Sebetsi seo e hlobane ditlhare tsa momotori ho ntlhaefatsweng eo e bolelang, e hlokang mekhansime e leng e ne e nyane ho ya kotsi.

2. Ho se tsamaisa momotori wa boleng jalo ho na le ditshwaretso tse pedi, le bothokiso jalo ya rotela e ne e nyane ho ya kotsi ha dikotlakotla tse tswanang lefatso. Bothokiso jalo ya rotela e ne e bao dikotlakotla tse dirimelwang, e tsebang thibello ya ditjhoriso tse di latelang lefatso. E ne e bao dikotlakotla tse ding tse di latelang ho ba le ho iletsa ditlhare tse pedi.

·Feti ya motlhaleho

1. E se tsamaisa relayasitši tsa seriling, dikotlakotla tsa moguruoa, le base tsa sekgauso sa sekgauso sa sebopeho ho latela ho reka thibello le sebopeho.

2. E se tsamaisa relayasitši tsa sekgauso tsa diphetogo tse di latelang ho ba le ho iletsa ditlhare tse di latelang ho ba le ho iletsa diphetogo tse di latelang ho ba le ho iletsa ditlhare tse di latelang.

3. Masechaba a le ha ho hlabana lefatshehang ho sebediswa, ke botho bao ba fetileng le botho ba tse pedi ba sebedisang ho ya ka mabopelo a lekhoa. Ba hlola ho feta kotsi le ho senya ho senyetsa mamello.

4. Sebediswa se sebeletsoe se sebelela mokete wa moholo oa mongwe le ho hloka mokae wa mosebetsing. Ho sebediswa ka mabopo a matlhaeng le diketong tse dihlakameng tse ding tse dihlaka lehoahlano, e leng e bile ho sebediswa ho latela 1 milione tse tsebiu.

·Mokgwa wa thibela, motlhalehi wa oile

1. E ne e sa sebediswang kgotso ya mogele wa oile ho sebediswa mafelong a mangata a tsamaiso le mafelong a mangata a phatlalatswego ho ile a reng, le mafelong a mangata a phatlalatswego ho senyetsa ho baletswe le ho baletswe.

2. E ne e sebediswang kgotso ya sekome le letlotlo la thibela la selemo, le glass le ho ba lekanyetsong le lining ea kopanong le movement ea kopanong ea selemo ho senyetsa mamello le ho latela meserithiso.

Tseleng:

| Model | STS-100 | STS-200 | STS-300 | STS-400 |

| Lebaka la hloko(mm) | 150 | 200 | 300 | 350 |

| Fetsing(mm) | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 |

| Tshwanelo(m/min) | 16 | 16 | 16 | 16 |

| Motors(Hp) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Hlakola dintlha tse di lekana | Φ45 | Φ45 | Φ45 | Φ45 |

| Nomoro ea pose e fuputsoa | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) |

| Fetolaetsano eo hlahileng diametre | Φ34 | Φ34 | Φ34 | Φ34 |

| Mashina ea fetolaetsano ea hlahileng | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) |

| Mabaka(a metsi) | 1.6×1.0×1.5 | 1.6×1.05×1.5 | 1.6×1.15×1.5 | 1.6×1.2×1.5 |