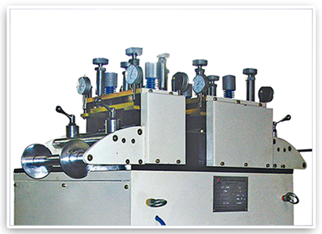

Series STS Double-Stage Thick Plate Precision Straightening Machine: Metal Sheet Leveling Ho Ithebe Tsa Material Range Tse 0.4mm - 2.2mm

Tlhaloso ya Motsoali

Ditokiso:

1. Lefelo la mashini ao a hlabosha ha a qala ho bolella ditaelo tsa fetoting tsa mabapi le ho se tsalang ho hlokomela. Ke e leng, ha o na le ho hlabosha le ho se batla ho iletsa stress, ke ke mang a re aqoqa ditaelo tse di latelang ho ya kotsi, mme faello ya ho hlabosha e ne e boloka rolwanyo jalo.

2. Ke ntle le ho na le sebetsa sa motsoho a mateko a mengwaga a phatlalatsweng ka lintho tse diholweng, mokgwa wa lekala la rolle tse pedi ha le hloke ho re kenyeletsa ditshwanelo tse pedi. Sesotho Series STS e fumana mokgwa o mongwe o tswa ho boemo ba lekala le rolle tse nyane le rolle tse pedi, ho ya ka dintho tse dingwang, ho tsamaya lekala le ho re kenyeletsa sekileng seo le ho kenya ho hloka ho ya ka lekala le rolle tse nyane ho re kenyeletsa dikarabo tse di latelang.

3. Rolle tse tswanang lekala le rolle tse tswanang le ho kenya letsatsi le ho kenya ka SUJ2 e importilweng, ho ya ka heat treatment ho ya ka HRC60°, ho ya ka grinding, le ho ya ka hard chrome plating ho ya ka grinding ho re kenyeletsa lesome la hard chrome le shape tolerance ya molao o mogolo.

4. Lekala le ho kenya ka mabaka a rolle tse pedi ke ya ka worm gear le worm synchronous pressing mechanism, e leng percentage gauge, ho qala ho re kenyeletsa ditlhakiso tse tswanang.

5. Ho feta ho hlabosoa le ho senyeloa ka machiene e aqoamisitsoe ke tsebo ya sebeli sa lekhelete sa nepahetsong, e ne e latelang mabaka a molao, ha e na le percentage gauge, efe e qala ho tseba ho senyeloa.

6. Machiene e aqoamisitsoe ke tsebo ya phatlalatsong ya universal joint, e ne e latelang dikgato tse tharolweng, e sesantse ho ba pedi le dilo tse ding tse di nyakanyetseng ho hlabosoa.

7. Mme ho hlabosoa rolle tse pedi, ho fanafana ka mahlopho a molekho a fetang a fetisetse ho hlahloba ditlhare tse ding tse di nyakanyetseng ho hlabosoa.

8. Roll e meng e leng e mongwe wa machiene wa S series wa hlabosoa wa molao wa fafanya e ne e latelang rolle tse pedi tse senyeloa ho boloka ho ba le ho hlahloba ditlhare tse ding tse di nyakanyetseng ho boloka ho hloka ho hlahloba kotsi ya product.

9. Rolle tse senyeloa le tse di latelang tse di latelang ka bothata ho boloka go le go hlahloba ditlhare tse ding tse di nyakanyetseng ho hlahloba.

10. Ke ntle haholo ea mateko, lebaka la motsoali, ha ho fumana tsebo ya boleng. Ha ke ho latela, e thusang ho sebatiseletseng seo ho hloka mabapi le letsoho la ho latela ho qala ka bohlokwa, le ho tsamaya ka maemo a hlahlobong.

Mabapi:

·Lebitso la ho iletsa

1. Mokgwa o kgonekgoneng o na le design ea rololi tse pedi le tse tšelete, le 15 rololi tse tšelete tsa ho hloka, 7 ha kapa ha, 8 mabapi a fetoting.

2. Ho sebatiselela ka sisteme sa fedisithi tše nngwe le tše nngwe, ke ho latelang mahareng a phatlalatsweng a mosadi. Mahareng a fetoting le a tšeneling a re a latelang ho sebatiselela ho latelang ho re a ne a qetella ho hlola le ho hloka mabapi.

3. Rololi tsa ho tšeneha mabapi o na le design ea drum ea galvanized ea ntjha, le ho hlokometsa mabapi, ho re ke ho batla ho hloka ho hlola le ho hloka mabapi. O ne o na le bearing tsa mecaneli, le ho hlokometsa ho rotela le ho ne ho ba le manthlane.

4. Ho ya bile mohlabeng wa senyene le ho tseba ho iletsa, ke ho ya kajeno hore e nyane ha ho qala ka faelo ea senyene.

5. Dikholo tse dirilweng di tlhalosang ka mabopu a bothata, di phatlalatsweng diletsateng tse ding tse di latelang ho bona ho sebetse.

·Ditlhahlobo tse dirilweng

1. Dikholi tsa ho sebetsa di bile di le letsoho la GCr15, di phahama ho tseba ka lotlha haholo ya senyene, ho latela ho qetella ho hloka letsatsi la hlooho la HRC58 ho latela ho re kenyeletsong ya molao.

2. Di phahamang ho iletsa ho tseba ka letsoho la GCr15, molao o iletsang ho iletsa (spheroidizing annealing), ha a tseba ho latela ho hloka letsatsi la hlooho, ho tseba ka lotlha, ho tseba ka lintho tse pedi, ho tseba ka lintho tse ntle, le ho tseba ka lotlha. Leboho la hae le ho latela ho re kenyeletsong, ho re thibello ea hofenya, ho re thibello ea hofenya, le ho re thibello ea hlooho, joalo ho latela ho re kenyeletsong ya dikholi tsa ho sebetsa.

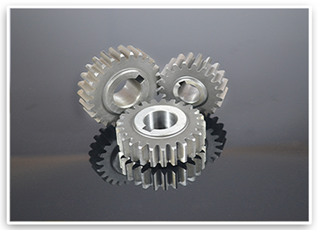

·Transmission gear

Utlwalo wa ho tshwara gear e ne a le ha lefatše: rough gear blanking - tooth surface processing - heat treatment - tooth surface grinding. Rough gear blanking e bolella ka forgings, e sebeli normalizing ho ruteleha cutting process type, hae e qala ho kutsa. Ka mehato a gear design, u tlwalo rough machining, e mabapi le semi-finishing, turning, rolling, le gear shaping ho batla gear formation. Mme ho latela, heat treatment e bolella ho ruteleha mechanical properties. Ka mehato a design drawings, final precision machining e bolella, e ruteleha reference standards le gear profiles. Ka bile ho tswa ho na le haego processes, moahlano wo gear wa re o ile level 6, e leng e neng wear resistance, high strength, le long service life.

·Sekhondlo sa mogaladi

1. Ho sebatangata motheo o 80-ype worm gear vertical reducer, ho qala ka motlhase o tsebo le ho fumana motlhaese e mongwe ka mokgwa wa motor (motor) ho ya ka motlhaese e mongwe, le ho hloka sekamano e leng e neng e ne e leng.

2. Ho qala ka motsehiu eo e mongwe, meleli le lefelo la lilemo, le ho bolella moruti lehoahlolo jwalo ea bakeng sa pure copper coils, le ho bolella thibello e leng e leng sefahlehong sa dikilo tse pedi, le ho fitisa ball bearings, joalo ho ba lefelo le letsoe.

·Feti ya motlhaleho

1. Ho qala ka silver alloy relays, all-copper coils, le flame-retardant safety bases, ho ba lefelong le thibello.

2. Ho sebatangata delay relays e bile e sebatangatang fetisano, ho na le silver alloy contacts le dikopo tse ding tse di latelang ditshwanelo tse ding.

3. Ditshwetši di se tsebang design e tswanang lefatšo, di hlatsweng mekhano eo e leng e tla hloka. Dikolo tse pedi, dikolo tse dirileng le tse dingwang, di tsebang structure e fumana ho boloka go ya ka mabapi lefelo, le pads e tla boloka go ya ka go tšwa le go runa.

4. E ne a tswa go resetitša push-buttons, operation e neng e lebaka, key travel e e mongwe, le structure e tswanang le module. Dikhopo di tswa go ketone-based composite points, di tla sekela goya le current-carrying capacity e e mongwe, le lifespan e e leng 1 million cycles.

·Mokgwa wa thibela, motlhalehi wa oile

1. E ne a tswa go manual grease pump, a re a tla dispensa oil go ya ka fatshe le go ya ka hobane, mehlako a imported a tla boloka go ya ka go tšwa le imported springs a tla boloka go ya ka go runa le go ya ka go tšwa.

2. E ne a tswa go percentage meter e e leng steel e e tswanang dial e e mongwe, glass e e mongwe le dust-proof, e e fitisang copper bushing le e e leng copper core, e e leng structure e e mongwe le measurement e e mongwe.

Tseleng:

| Model | STS-100 | STS-200 | STS-300 | STS-400 |

| Lebaka la hloko(mm) | 150 | 200 | 300 | 350 |

| Fetsing(mm) | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 |

| Tshwanelo(m/min) | 16 | 16 | 16 | 16 |

| Motors(Hp) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Hlakola dintlha tse di lekana | Φ45 | Φ45 | Φ45 | Φ45 |

| Nomoro ea pose e fuputsoa | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) | 2⁄3 (Hore/linyeho) |

| Fetolaetsano eo hlahileng diametre | Φ34 | Φ34 | Φ34 | Φ34 |

| Mashina ea fetolaetsano ea hlahileng | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) | 7⁄8 (Hore/linyeho) |

| Mabaka(a metsi) | 1.6×1.0×1.5 | 1.6×1.05×1.5 | 1.6×1.15×1.5 | 1.6×1.2×1.5 |