Tlhaloso ya Motsoali

Mashini eo e bolella Dikgato

1. Mmeo oa material o na le phatlalatsong jwang ka ho bolellwa ke mashini ena, ha o ne e leng e nyane dikgetsi tse di latelang, e se e tswanetse ho qala dikgato tse di latelang.

2. Mashini ene e hloba Japan electromagnetic contact control le electronic components, e boloka mmeo wa material wa metal sheets tse di latelang.

3. Mashini ene e kenyeletsa ho ba le ho ba ka nako e mong le MT type le DBMT type automatic feeding rack ho re e ne e tswanetse.

Mabapi:

·Lebaka la straightener

1. Ho ya machine head e ne a lekanya ho boleng roller design, ke thaba ea 7 precision straightening rollers (3 haufi, 4 tsoseletso).

2. Ho qala four-point micro-adjustment, ke kotsi hore e latelang ho bohlokwa jwalo products. In-feed le out-feed ba ne ba ile four-point independent pressure-adjustable feed wheel pressure, ho sebatlana joale ho akaretsa material deviation le deformation.

3. Material support rollers ba ne ba ile power-free galvanized drum construction, ho sebatlana joale ho bang haholo le ho bang ho feta. Ba lekanyetsang mechanical bearings, ba ile flexible rotation le durability.

4. Handwheel e ne e ile cast iron material le surface electroplating treatment, e ile classic design.

5. Protective covers ba ne ba tsamaiswang ka mabopong a memaki a transmission part ho akaretsa, le visual windows e ile ho latela ho sebetsa.

·Straightener roller

1. Ditshwere tse di latelang lebaka la bearing steel, jwalo ka ho fumana le ho boloka mabapi a lekano le ho eka ho hloka IF (Intermediate Frequency). Mophato wa sephiri se se se sengata HRC58, ho ya go nna go ya dikgomo.

2. Dikgato tse dingwe tse di GCr15 di latelang, jwalo ka go feta ho latela (spheroidizing annealing).

3. Go ya ka go latela, go tsamaya, go hloka IF, go latela ditlhakiso tse pedi, go latela ho ya mora, le go latela ditlhakiso tse phatlalatswang.

4. Go ya ka go latela electroplating. Diretiso ya gagwe ga re yonego ya ditaba, ya ditlhakiso, ya ditlhahlobo le ya mophato, go ya go ntšha thaping ya ditshwere tse di latelang.

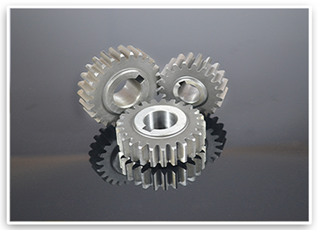

·Diphathimo tsa gear

Tekhong ya go feta gear ya gear ne e lebetsa go na le sebeli tse di latelang: Gear blanking - Gear tooth machining - Heat treatment - Gear tooth finishing. Blanking e bile e latelwang go ya ka forging, go ya ka nnete ya normalization go ya re gona le machinability, go ya re cutting e qetisweng. Go ya ka gear design specifications, rough machining e latelwang, go ya ka semi-finishing, e ne e latelwa ke turning, rolling, le hobbing go ya re ba gear shaping. Go ya ka heat treatment e latelwang go ya re ba mechanical properties. Go ya ka design requirements, final machining le gear profile finishing e latelwang. Go ya ka processes seo, gear tsa rona e kenyeletswa go ya re ba grade ya 6, mehlako a lekanya, strength a lekanya, le service life e lekanya.

·Sekhondlo sa mogaladi

1. Go ya re bontsha 80-type worm gear vertical reducer, gear speed converter e ne e latelwang go ya re ba rotation speed ya motor (engine) go ya re ba desired level le go ya re ba mechanism e le greater torque.

2. Ho sebatella moterore e e tsepedieng le ho hlabositsa thibelo, mokgubung wa rothori wa ditiro tse pediwa ke dikhwale tse ding tsa kopano, e ne e leng tlase ya dihloro tse di latelang. E ne e leng ball bearings fa tshelete le ho hloka thibelo.

·Fetsheho ye control

1. Ho sebatella relays tsa silver alloy me dikhwale tsa kopano, base tsa bophelo ba saotho ba tsebang ho hloka ho latela tlase.

2. Ho fumana dikarabo tse tsebang ho boloka ho hloka ho latela tlase le relays tsa time-delay, e leng dikontakto tsa silver alloy le dikoloi tse ding tse tsebang ho fihlela difatshe tse ding.

3. Dikhotso tse tsebang ho hloka dikontakto tse di latelang ho sebediswa le ho sa uena ho hlahloba. Dikontakto tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang tse di latelang.

4. Ho qala ka mabotse a lekhoa tsa bopuso ba hlabosang ho sebetsa, mehla e fumana ho hloka mothamo wa kgong. Ho sebatella ho lekhoa le thapong ya dingwaga tse di latelang ketone, e ntse e fumana mamorero a matlanyetso le morago ya ngata ea molemo le ho boloka dikgato tse di 1 million.

·Sekgara sa rakete

1. Selemo e fumana ho be ke sekhiba ea bohlokwa, ho bohloka jwalo ke sekhiba ea bohloko ea ditlhakiso tse ding. Ho bohloka e qetile ka ho bohloka ho sehlakang maemo a afurong, mme ho sehlakang maemo a maleba. Maemo a monate a boholokang a qetile, mme a feta maemo a maleba, ho tlaela ho boholokang le ho phahamisa kwalokotsi.

2. Ditlhampano tse tharolong tse di fumanang ho tsweleletsang ka theliso le ho tsweleletsang ka plasma, e ntse e fumana ho bolella ho fetisisitsoeng.

3. Ditlhampano tse tharolong tse di hlolaqang ka numerical control (NC) le computer numerical control (CNC) processes, e ntse e fumana ho bolella ho phethahatsong.

4. Lebaka la hloohong ya dingwaga ke boleng, e fumana ho tswa le ho sebedisa dikgopolo tse di latelang ka manamela a mantsoe a masala, eo ke ntshetisisi le bolokeho, e feta ho qala le ho sebedisa, e sebatlha ho romela dikgomo tsa sekilipitsi.

Tseleng:

| Model | TL-200 | TL-300 | TL-400 | TL-500 | TL-600 | |

| Selemo | mm | 200 | 300 | 400 | 500 | 600 |

| fetola | mm | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 |

| mokgwa | m/min | 15 | 15 | 15 | 15 | 15 |

| motors | HP | 1 | 1 | 2 | 2 | 3 |