Lihao Machinery'nin çözümü, ısı değiştirici kabartma üretimi için özel olarak tasarlanan ileri düzeyde bir damgalama hattının entegrasyonunu içeriyordu.

Otomatik damgalama sistemi, düzeltme özelliği olan güncellenmiş bobin açma makinesi, NC besleyici, damga kalıbı ve güç presinden oluşmaktadır ve metal plakaların yüksek hassasiyetle şekillenmesini sağlar. Sistemin otomasyonu insan müdah介入ini azaltır, üretim hızını artırır ve büyük hacimlerdeki ısı değiştirici kabartmalarında sürekli kaliteyi garanti eder.

İşlerimiz, ısı pompa ve bölgesel ısıtma bileşenleri dünyasındaki önde gelen üreticilerin üretim verimliliklerini ve kalitelerini artırmalarına yardımcı olmuştur.

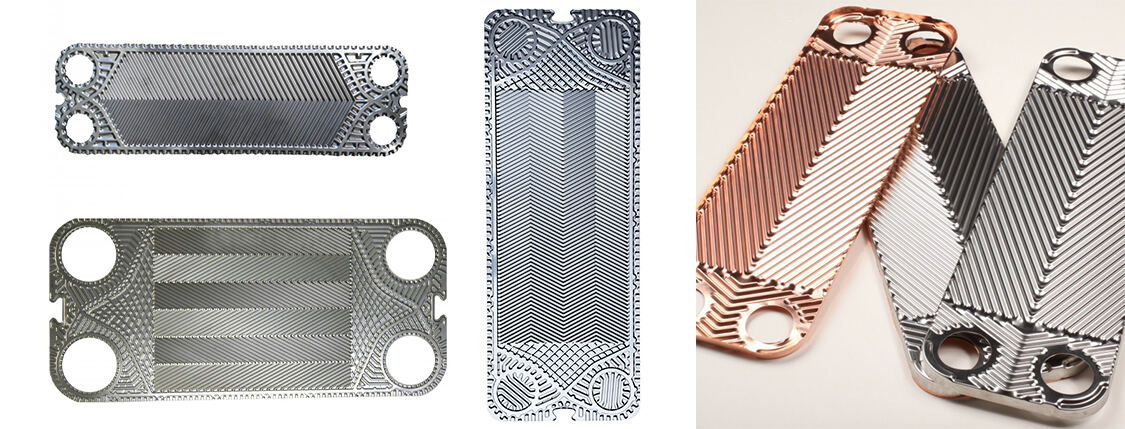

Isı değiştirici üreticileri, karmaşık desenlere sahip yüksek hassasiyetli plakalar üretirken döngü süresini minimize etmek ve malzeme kullanımını maksimize etmek zorundadır. Bu plakalar, ısı pompa ve bölgesel ısıtma gibi endüstrilere özel olarak, sıkı kalite gereksinimlerini karşılamalıdır. Müşteri, üretim süreçlerini kolaylaştırmak ve malzeme değişimleri sırasında duruş zamanlarını azaltmak için verimli ve yüksek güvenilirlikte bir damgalama çözümüne ihtiyacı vardı.

Lihao Makine'nin çözümü, bobin işlemeden bitmiş ürün'e kadar olan tüm adımları ele alabilen tamamen otomatik bir damgalama hattıydı. Servo motorlu, sıkıştırma tipi besleyici sistemimiz, ince, orta ve kalın malzemeleri yüksek konumlandırma doğruluğuyla işleyebilmesi için tasarlanmıştır ve hızlı malzeme besleme ve kesin sonuçlar sağlar.

Ayrıca, sert çatılardan yapılmış ve yenilikçi mekanik sürüklemeli sistemlerle donatılmış basım makinelerimiz yüksek ürün kalitesi ve hız sunar. Bu sistemler, müşteri siparişlerine göre üretim çıktılarını yönetmek için tamamen özelleştirilebilir. Enerji verimli operasyonları, düşük gürültü seviyeleri ve az muhafaza maliyetleriyle damgalama hattı uzun vadeli güvenilirliği sağlar.

Isı değiştirici plakalar için modüler araç takımı, metalleri damgalama matrislerini değiştirmek suretiyle çeşitli plaka tasarımlarının üretilmesine izin verir, bu da araç maliyetlerini önemli ölçüde düşürür.

Lihao'nun damgalama hatının uygulanmasından beri, müşteri üretim verimliliğinde önemli iyileşmeler gözlemlemiştir; döngü süresi azaltılmış ve malzeme kullanımı artırılmıştır. Damgalama süreci şimdi karmaşık desenlere sahip ve minimum varyasyona sahip yüksek kaliteli ısı değiştirici plakalar üretmektedir, bu da atık oranlarını düşürme ve üretim maliyetlerini azaltma sonuçlarına ulaşılmasını sağlamaktadır. Esnek hat farklı plaka tasarımlarına hızlı bir şekilde uyum sağlar, çeşitli müşteri gereksinimlerini karşılayarak yüksek çıktıyı korur.

Lihao Makine'nin ileri düzeydeki damgalama hattı çözümü, müşterinin optimal üretim verimliliğini ve üstün ürün kalitesini elde etmesini sağlamıştır. Damga kalıbı tasarımı, esneklik ve yenilikçi teknolojimiz, ısı değiştirici plaka üreticileri için çözümlerimizin en iyi yatırım geri dönüşünü ve endüstride uzun vadeli başarıyı garanti etmesini sağlamaktadır.