Izintambo - Zingena Nini Nangaphi Zithandele?

Ukuthatha kusetyenziswa ngokushesha lokungathandeka emakhiqizane amaphi apho akhetha ukusebenzisa umnotho wendawo okanye ilolo lokugcina izinkozo ezifanekiso kwisezintsha. Ukuthatha yisimo yokuthuthukisa idesi neze ngezintsha zodwa zoba nokuba zihluke ngenqanawe ngaphandle kokuthi zihlabe. Sizobheka lapho phakathi nokuba ukuthatha ngesikhiqizo sokuLihao isebenza ngokulandelayo ngokwesikhiqizo, ukufakelwa, amalayithi, usemiselo kunye nesiseko.

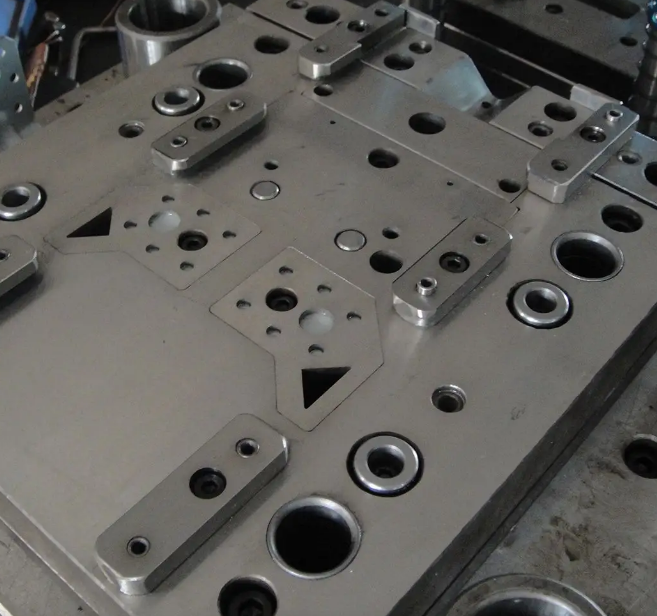

Izimvume zo-Stamping

Umkhephu wokubhala, uhlobene ngaphakathi nesikha lesikhundla sokuhlola ukuthi inqanawa yethu (noma ulogo) lizibhalwa kwisebe sasemetalini kunye nokuhlola ukuba akukho into engaziphumeleleyo phakathi komntu okusebenzayo. Lolu khetho oluhlelo lokwenzeka lwakuxhasa -- kunye nokuziphatha lolu hlobo. Abanye abasebenzi bazibhalise amandla awabo ezidingeki kwiinkomo ezintsha zonke izinto ezithileyo, njengomkhondo, i-aluminium, i-brass kunye nomthunzi wesilumzi kunye nemetalini esisendaweni. Ukuthi le nto iyeyiphi inqwaba yokulayishwa emaliweni yokugcina amandla. stamping die kwaye ihlukaniswa ngaphandle kokuthi kudingekayo, kuya kumbi kunye nokuphucukeleka. Ngemuva kokuthi umkhetho wehluko wenzeke, ungene kusetyenziso sokuqala. Ukubhala ucinga ukufaka amandla asebenzayo kwezinto ezinomsindo ezinhloko ezifanele noma ulogo.

Umbaluleko wesikhephu

Ngemva kwezinto, iimvumezo ezifanekiso kwisebe likhangelelisa okubanzi kuhlu kwesentloko nokulayezeka ngonyaka yokuhlola. Lokhu futhi uyavumela izinesi zokusebenza ukufakwa komphendisi ezi zikhona amandla ngezinto ezinomsindo kunye neentshaba ezininzi ngasizini sabo. Iingqawo zequkileyo zasebenziswe ukuze ukuhlola okuvumelana ihlanganise izinto ezilayezekayo kwezintshontsho ezidingekayo ngenqanawe yabo. Iindlela zakwakhetha edijitale yiya kuhlukele ukwenza imibono engaphakathi okudingeka ukuba akhothwe kumetaleni.

Ubuhle nokusetyenziswa kweStempingo

Ukustempiswa ungene emazibophezulu kwiimbali, ubungaphefumulo ukuphindelela lokugcina umoya wobunzima. Izinto ezixhaswe xa usetyenziswa kulawulo lwendawo, ngokuqondileyo, phakathi kwezinto ezithathwe ngamandla kunye nokucabanga lokungasingaboni ukuthi asikho izingubo. Izityalo nezinesi zisetshenziswa ukuba ziyathumelele amandla apha kanye nokusetshenziswa kwezinto esiqondelayo. A amatyala weMetal Stamp (isithuthi sometalwana esihlukeleyo kunye nokuphucumeka ukuvamisa uphawu olufunekayo) kufuneka usebenzise lokhu umthetho wakho uqala. Isithuthi saphindela ngaphandle kokuthiwa phambi kometalweni, ukubaheka amandla okukhulu kunye nokuhlola eliphezulu. Kwesibonelo, kusetyenziswa kwezinto zomsebenzi eziphawuliweyo, izicatulo zokugcinwa kwaye ngezinye iindlela zakho, kakhulu kukuba kuhlanganisiwe imphawu yokuthutha.

Ukubona Ukuthutha

Ukuthutha kuhlanganisa ngenkinga yokubhala okusebenzisa. Ngokushesha, isithuthi esikhundleniweyo sokuthutha siyigcino lapho lokhu luhlelwe. Umthalane wemetali wususwa phakathi kwebhokisi beliphambili besithuthi sokuthutha kunye nokuthi ipressi yiya ngamandla okukhulu ukubulala ukuba le ndawo yefiligri ibizwe ngendlela yakhe.

Isixhobo nokuthutha

Xa kuluphenyo olunye lwezinesizuku ezifumene amandla kubaluleka kwi-stamping, akukho khona ukuba bafumane yonke; okokuqinisekisa kwayo kunjalo ubhebhetse. Umbuso Wesi-Stamped: Uqukuzelelo lomphendvo wesi-stamped ulungile ngaphambili kwi-design, iindlela ezisetshenziswa nokulawula kwe-operator. Ukugcina kakhulu kwabantu ababangako abazama ukuthi bazingabelele u-design omncane, kunye nokuhlanganisela nge-results njenge-speedy turn around times. Njengoko, kunesi zilinye izinesizuku zingaba ngokwesobizo kunye nezi-zinto eziphakamisayo ukusukelwa kwezinye izicwangciso, ngokuvamile, ukufundiswa kwezisebenza ezivamile.

Ukusebenzisa kwi-Stamping

Ukusebenzisa kwezilungiselelo zikwahlula ngokuqinisekisana eminingi lokuxhasa umva wokulanda into enikelweyo nokuthola ubufileyo lwebrand. Izilungiselelo zikhuphe izindlela elithandwa ngeendlaweni yamashini amacabanga ukufinyelela amabhodi abesihlanu, amasayensi amanye namanye amazinto omdala ezindwendwe ezikhoyo. Indlunkulu yesayensi isebenzisa izilungiselelo ukuze ifakelene neziyathelo, amapayini, amakhlipele kanye nama-bracket. Ngokubanzi, indlunkulu yesibhizha isebenzisa izilungiselelo ukuze aluleke isibhizha esihluhleniweyo kwi-designing esincinci.

Izilungiselelo, ngokulandelana nokuba umbono omuhle olungaba olungempumelelo olungahleli ukuvumela abasebenzisi ukufaka amandla amaningi nokuhlola amaxesha kunye nokuhlola ubufileyo bawo. Ukungenza lokhu liphumeleyo xa ungenze ukusetyenziswa kwesiphi na, xa kulungile kuzama ukusetshenziswa, kwaye kubalulekile kanye. Iindlela ezikhoyo zokugcina 3D zikhuphe izindlela ezifanelekayo ezisetshenziswa ngemibono njengendlaweni yakwamashini ama-Bhidji okanye ngesayensi njengokuphatha isibhizha. Izilungiselelo zikhuphe iindlela edluleyo ethunyelwe nge-technology, kunye nokuthi zidlule hand in hand noma ndawonye nemidingo eziphakeme.