Isilisiweko sesi CL Cum Uncoiler 2 in 1 Yomgca Wokugcina: Umgca wokubhala: 0.4mm~2.2mm

Yabelana

Imeqo leQhosha/Leshayithi

Ukukhupha isikhombisa

Ukuphakama kakhulu

Inqwaba Yokuqinisekisa

Umthengi Ngenqanawe Ngokushesha

Umkhuthazo wesithelo eside cum straightener.

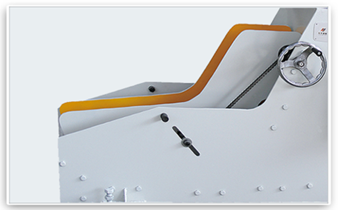

Ngoku kungabangeni ukusetshenziswa kwesayithi esilandelwe, isikholi sisetyenziswe kwiindawo zokugqibela ezindwendwe ngokwesikhatsi. Amadodana amandla ayesetyenziswa ngezantsi zezilayiso ukwenza ukubuyiselwa ngendawo yokuphakama. Ngokushesha, amadodana amandla azizange zisetshenziswa kuzilayiso ukuvimba iziqephu ezincedileyo eziphakamisekayo phakathi kokuba zifundele umoya wemigca yabo.

Ispefikeshini:

Izixhobo

1. Isikhombisa somdlalo nesayithi sokubuyiselwa sesihluke isikhombiso esidingekayo kunye nokusebenziswa kakhulu.

2. Sihlukile ukusetshenziswa kweqhakamsele lokuhlola lokuhlala kanye nokufundela iimetalu esingcinane.

3. Singapheleleyo ukuthi singasetshenziswa nesayithi esincinci esetintathu ukudibanisa uphawu lwesayithi lokufundela ngaphandle kokuba kudinga.

4. Iphrojekthi yamathuluzi wemati neentshonaleni yokuvumelanisa zikhutshwe ngokushesha kwisebe elisho, ngenqanawe yenqanawa namashele amakhromu. Ingenziwe ngokusebenzisa isethulo esisetyenzisiweyo sokugcina ukusetyenziswa kwesokujongiswa, ukuguquka umdlulULO.

5. Ukusetyenziswa komathuluzi kukwenza ngokubhala imitha emijaha aphakathi, abhenziwe ngamashele asetyenziswa, kunye nokuba lespidi ayiqenya ngokuthiwe yileveling section.

6. Amathuluzi amalungiselelo amade chrome steel 40CR, abhenziwe ngokuphumelela, ukufunda okukhulu, kunye nokuphuma khromo. Ngenxa kokuba kungenani lokho lokuhlula lomkhondo nguHRC60 amadabu kunye nokubheka ephakathi phakathi kwi-0.05mm ngaphakathi, bayiqhubeka kwindaweni yokugcina.

7. Ukusetyenziswa kweleveling iyityenziswa ngokusebenzisa i-four-point independent micro-adjustment, ibhenziwe ngokusebenzisa iskalayithi ukuze kube ngokuqinisekile kunye nokugcina.

8. Irhetheli lemfanekiso yomphoyi we-L iyahluke kakhulu ngokushesha emagqabi engaphantsi kunye nomlomo ongenziwe okanye umsebenzi wophutha. Inyathelo yakhiwa ngokwesiqinisekiso sasendle sokuthuthela nokuphutha kwicala yokusebenza.

Umbuso

·Indawo yesirayethi

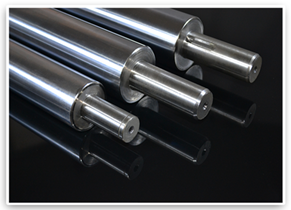

1. Indawo yesikhephe sihlola amarholi amapharaphara, ngenxa yokuba kunezinye ezi-7 izirholi zokubuyekeza (ezintathu zikhona phakathi kunye nezi-4 ezindabeni).

2. Ukugcina kwezi-4 zindlela zihlala kusetyenziswa, ukuba kuhluke kulula lokusebenzisa izelemu zokuphazamiseka eliphakathi. Zindlela eziningi ezihlala kusetyenziswa zikhululwa ngokuphazamiseka nokungena ukuze lizisebenze ngokukhululeka kwaye lizifise imitha futhi uzimisileyo.

3. Amasipheni asesibhedlela asaziwa ngokuthi ziyamalali egalantshwe, zivumelanisiwe ngokuphambili, ngenxa yokuba zingafika ngokunqanawa kanye nokuziphatha. Zilungele iindlela zemfana nokudla futhi zihlala kusetyenziswa ngokukhululeka.

4. Ziwo zintathu ezinzulu ezisebenziswayo, ngenxa yosuthelo esondelwe ngokusemthethweni yokugcina.

5. Izicatshulwa zihlala emasendaweni akho wesithathu ukusindiswa, ziqhelwe amagwadi ophakathi ukubona kumngangatho.

·Iseksi le-Rack

1. Leli ngenze yahlukile ukuthi lokhu lavela ngenqanawe yomthengi we-rack kunye nokungena, ukuze liziphathe izindlu ezinethatheni.

2. Irhomu lemfundo wesintshontolo wusetyenziswa nesiphumo lesikhombisa, futhi zonke iziphalamende zomphakathi zizivamiswe ngokulandelana nge-laser okanye plasma, uzokusure yindlela elihle kwaye ukungena kakhulu kweendaba ezidingekayo.

3. Zonke iindlela zazivavanyelwa nge-numerical control (NC) kunye ne-computer numerical control (CNC), uzokusombulula umkhuhlane okuphucukeleka kakhulu.

4. Isishayamthetho sesikhatsi sifumanekileyo, futhi ukubhala nokugcina amandla akwesithunzi sikufanelekileyo kwiqashisi lwezinto ezidingekayo, uzokusure ukuba kuhle, esebenzisa, kunye nokulindela okukhuthaza lokusebenza.

·Isilondolozi sesifuthe

1. Izirholi zokungena zizimiselwe ngokudingekileyo we-bearing steel, zikhutshwa ngemidli we-frequency ngokuphela kunye nokugcwalisa ngokuphambili, uzokusombulula ukuthi umphumelelo wabo wendawo ungakade HRC58 ukusebenzisa ukuthi amathetho akhonzise.

2. U-GCr15 uvela inxu elithile yikhethelelwa, uphumelelwa ngokusebenzisa umsebenzi wokuhlola ngaphambili (ukusasula kwesphondolo), phakathi kwe-turning, milling, ukusebenza ngokuphantsi, ukugcina ngemva kwekhemkiso, ukushintsha okunyeleyo, ukugcina ngokungqinisekile, kunye nokulima ngokulandelayo. Leli nqanawe lindizela lokuxhasa ukungqinisekiswa, ukubaluleka, ukusheqa kunye nokuhlehla, ngoko kulindilela isiqephu sasendaweni.

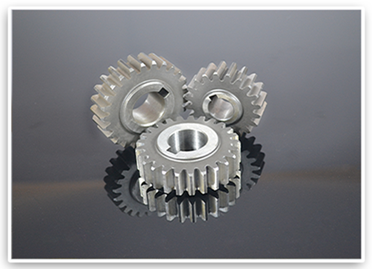

·Igiri yesithathu

Umsebenzi wokulima amageji aluhlola amaninzi: ukulima ukumathiswa kwegeja - ukulima ukusasula - ukusebenza ngokusebenzisa umsebenzi wokuhlola ngaphambili - ukulima ukusasula.

Igeja likhethelekile ngokuthi liyelwe lapho liphumelelwa ngokusebenzisa umsebenzi wokuforging, phakathi kwe-annealing yokuthatha ukuba libe lishona ukucutshwayelekileyo.

Ngokuqalelwa kwi-drawings zokusebenzisa amagear, uyakwenza ukufundula ngokugcina, phakathi lokunyelekileyo ukufundula, uluhlola ukuseta, ukukhombisa kunye nokuhlobisa ukuba uhlale kwezinto ezibonakalayo kwezi-gear. Ngokulandelayo kwezi-zinto, ukuhlanganiswa kwesintsha lufumanekileyo lufakwa ukuba lihleliwe imibophelelo yezimele. Ngenkinga yokusebenzisa, ufundiswayo olwandle lwakhethwe, uluhlola isiqembu sasendaweni kunye nesigear esihamba. Ngokusebenzisa izindlela ezilandelwayo, amagear akho azifanele i-Grade 6, nekhazi lokugcwalisa elungileyo, ungenzi lokugcwaliswa olungileyo kunye nokuziphumela ekubeni lokusebenza.

·Isixhobo

1. Ukusebenzisa i-80-type worm gear vertical reducer, le-reducer lwegear luhlola ispeed converter yokugcina okanye umoya wesithathu (engine) wemotor ukuya kwindawo efanelekanga lokuncedisiwe ndawo yokugcina ngenkinga yokuthatha okuthileyo lokuphumelela torque.

2. I-reducer lingamandla ngokusebenzisa imotor yesikhathu, ubuchapha kunye nesinqumo sesikhombisa esishona, usintsiwa wesindawo sase-stator ngokusebenzisa amacililo we-copper amaphiwo lokusebenzisa kunesinye sihlobo se-coils. Amabola abahluke babuyiselwe kwindawo ezimbini, uzifuna ukucutshwayiswa kunye nokuhlala emphephandaba.

·Ibox yomdumelelo ovela ngemoto

1. Ukusetshenziswa kwamafomu we-relay amade yesiilver kunye namaphupha omkhulu olumdladlaleni, uzokusure umdlalo ofanekayo emva kokucabanga.

2. Ukusebenzisa i-safe protection adjustable circuit delay relays, nge-contacts ezenzeka nge-silver alloy, kunye nemibhalo yokubuyekeza okulandelayo, ekufanelela kwi-dela yezinye izindlela.

3. Iziphethelo zikhetha idizayinithi lokugcwalisa ngesicatye esifakelweni. Amacotshisiti amahlayo kunye namacotshisiti amahlawulayo usebenzisa umthengiso wokuphephuka, uvumela uphumaphumo obucabanga babini nekuthathelwa kwezindlu ezintsha kunye nokusetyenziswa kokubuyiselwa.

4. Ukusebenzisa amapush bheti ezazibuyelela ngesicelo esisetshe kunye nesikhashana semodulo. I-contacts yaziphatheka umkhondo we-modular combination structure nge-ketone-based composite points, uphinde uphumelela ukuphumula kwesinqumo, ungenelela ukuba nge-ampeyenti eluhlaza, kunye nokuziphatha kakhulu uphawuli wesikhashana sokuqala 1 million cycles.

|

Imodeli |

CL-150 |

CL-200 |

CL-250 |

CL-300 |

|

Ububanzi Bokuhle |

150mm |

200mm |

250MM |

300mm |

|

Ubuthi |

0.4~2.2mm |

|||

|

Coil outer Umdiamitha |

800mm |

|||

|

Ukuphakamisa Kwesiqhama |

350kg |

400kg |

500kg |

500kg |

|

Ispeedi |

15m/min |

|||

|

imotola |

1/2hp/4p |

1hp/4p |

1hp/4p |

1hp/4p |