Imibhalo Eziphakamisayo Ngenqanawe: Ukubuyiselwa, Ukubuya, nokuhlola Kwesempeleni

Inqwaba Yokuqinisekisa

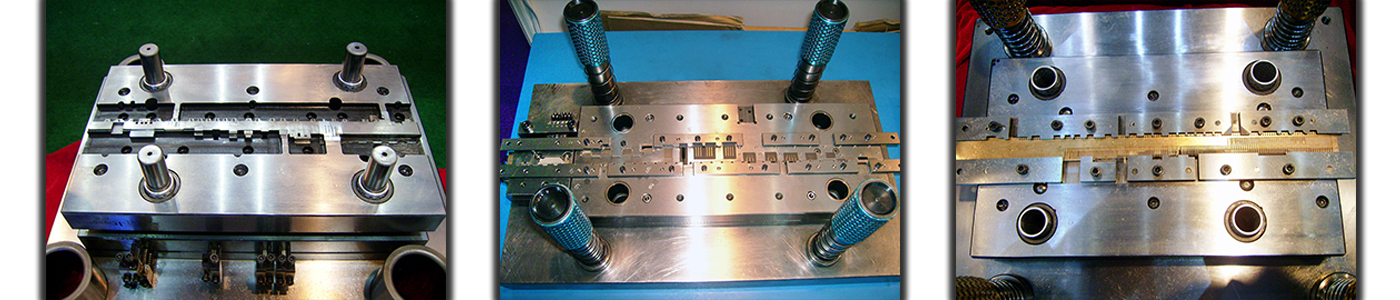

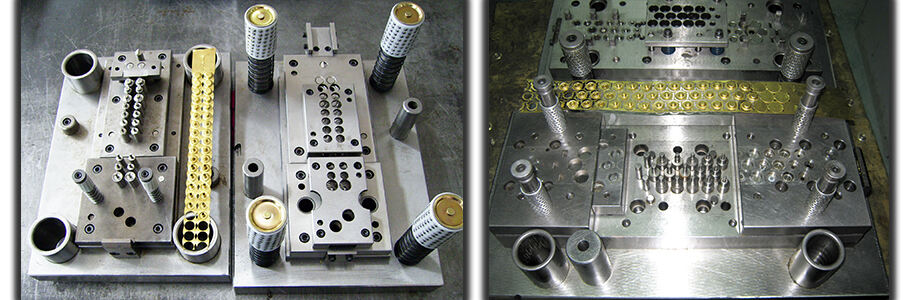

1. Umthombo: Imibhulandleli zithunyelwe ngemetalu yedlula eyahlukileyo noma iimloya espezhialini ukuvumela ukuba akukho uvuselelo nokuhlinzekiswa.

2. Isトラucture: Isトラucture sokuthatha lusetyenziswa ngokuba imibhulandleli, lokugcina, ilayisini, indawo yokuhlola, indawo yokuhlola, ngeke lihlale kakhulu ngokuba kufanele libe ngokuxhasa kunye nobungako.

3. Ukuphawula Kwesikhashana: Ukuphawula kwesikhashana kwenzelela ukuba kuhlanganise izinto ezilandelwayo, zifuna izindlela nezintambo ezikhoyo ukuphawula.

4. Isikhwama Sesikhashana: Isikhwama sesikhashana sithunyelwa ngokuba zingaki amathetho angavumelwa, umthombo wokuqhathanisa, nokuhlola.

Imibhulandleli zakuthatha zinakwabo amaxwebhu okanye:

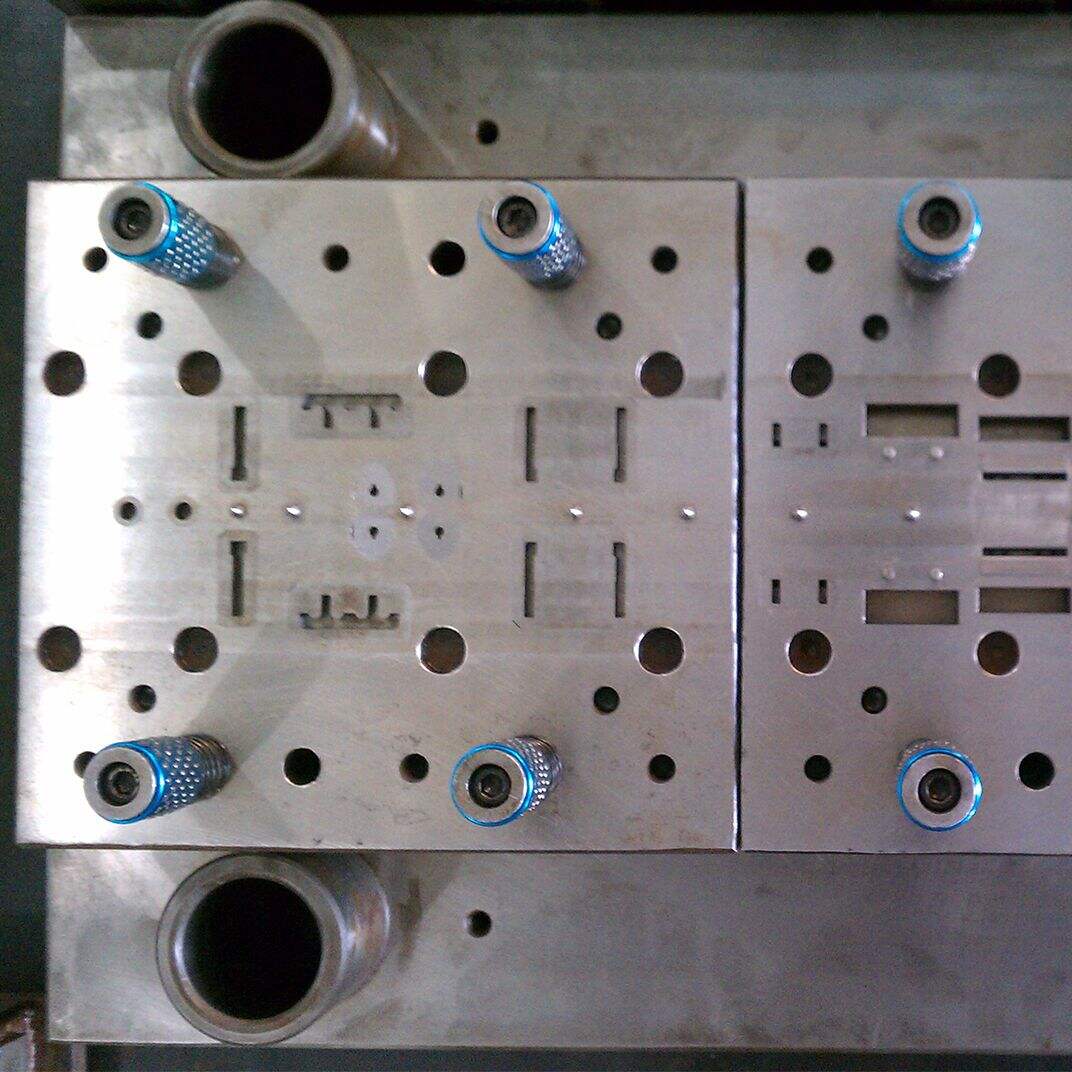

1. Ukugcina amakhiwo: Iindlebe zokugcina zizosetshenziswa ngokubanzi kwiqhathanisi lokusebenzela amakhadi, njengamabhedlela wekhayalethu, amado, amaphupha nokufanele.

2. Ukugcina amakhadi: Amashelwa angaphandle kwamakhadi amacayishoni, njengamakheli amaninzi, amaphethi, amalaptop, futhi, zisetyenziswa ngokubanzi ngeindlebe zokugcina.

3. Ukugcina amandla: Amashelwa amaphandle namandla, njengama-fridge, amawashing machine, amaaconder, futhi, zisetyenziswa ngokubanzi ngeindlebe zokugcina.

4. Ukuphatha imibhalo yamatali: Imibhalo emibini yamatyala, amathuluzi, futhi, zisetshenziswa ngokubanzi ngeindlebe zokugcina.

Ukubuyisela iindlebe zokugcina kufuneka uzame ukufaka amaparameteri ezi-ncinci:

1. Amadrawings wamathandi: Zikhululeka izithombezelo ezidingeki njengeesayizi, amashape, nokucacile kweentsingi.

2. Izicatshontolo zokumaterial: Zicinga inani lesihloko kunye nomphumelelo wesilayithi esetshenziswa ngenqanawe yenqanawe.

3. Imandla yokuhlelwa kwezinto: Bonisa amandla ahlola lokuhlelwa kwezinto, njengokuphela okanye elinye lamanani, ngezini.

4. Izicwangciso zomphakathi: Bheka izicwangciso zomphakathi wezinto ngokubanzi kwezinhlanga ezilandelwe kunye nokulandelwa komphakathi.

Izixhobo

1. Imbizo yethu yesayithi siyafikisana nesikhatsi sokushintsha kwesiphi esingaphambili nesiphi esiphambili, ukufuneka kwiindawo zakho eziphambili neziqephu, zemobayile, izixhaso, kunye nesiphi esingaphambili.

2. Zisebenzisa imiyambo yegama elincinci, ukuze kube ngemuva kokuba iSPM ye-200, amanani akwenzekileyo ayishumi emfuneko yomphakathi. Lokhu kuyenza ukuthi ubukhulu bokuhlola babeyahlulekile ngaso sasendaweni kunye nemiyambo, ukusuka ukungabangene ngesiphumo somkhakha.

3. Siyazi ukuba sidibane nokugcina ukusetyenziswa komathathu ngumthakathi wokuqala wesithuthi lesine% lokusebenza ngokubona nokuvumela amaproseshi, ukuya kuya kuziphatha izinkomo zethu.

4. Ngokusebenza, sizifaka umthombo wemathathu kunye nezinye zimakhiwo ezinikezela ukusetyenziswa ukusuka ukungavalelwa kakhulu kwezindlela ezinikezela kunye nokusetyenziswa kwezinye izinto.

5. Ukugcina kwethu okwesetyenziswa kukwahlula ukusebenzisa izinto ezidingekayo zokuphawula amandla edifanekiseleyo lokushintshwa, usayizi, umgezo, kunye nomsebenzi. Ngaphandle kokuba udinga amandla adingekayo yokushintshwa, amandla abheqe, amandla aqhosha, amandla ekuthengeni, noma amandla aphephe, singakwazi ukuphawulisa njengekwiqheleni lwezindlela zakho.

Amagama amatekwana:

| Inqwelo Yomdlobheni | Imandla yeshintsho sometalu | |||

| Isopho esideyisayo | ProE, CAD | |||

| Iphawuli | Uphawuli olunye ,Uphawuli olungaphezu | |||

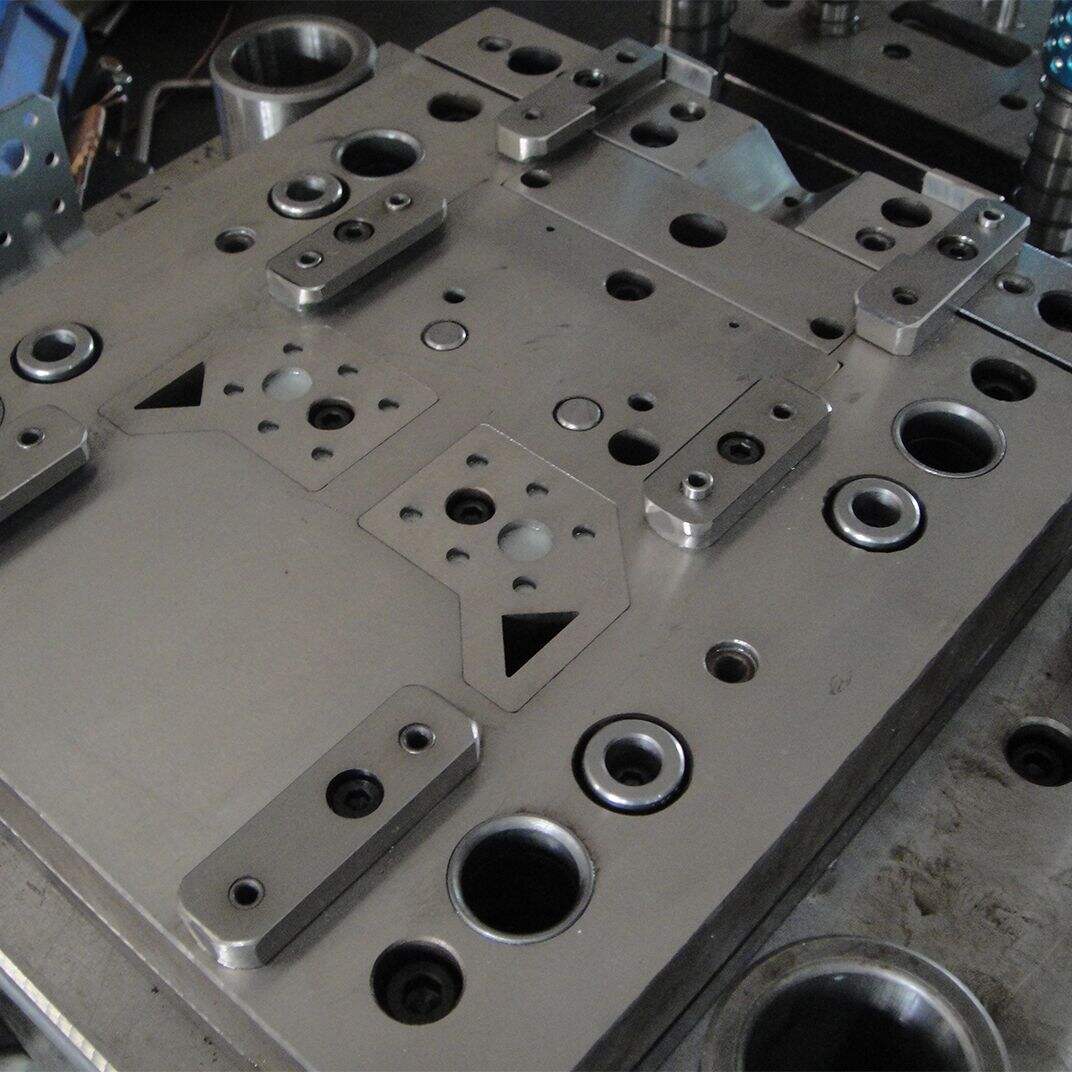

| Umthombo wematerial weMandla Engxenyeni | SKD11 | |||

| Umthombo wesihlobo sematerial | DC53 | |||

| Ipin yaseLeader Bushing | Ukuphakama kakhulu | |||

| Ukuphatha kwePunch | Ukulungisa ngokubenza kwiCenterless | |||

| Ukuphatha komphendulo wemold neinsert | WEDM-LS | |||

| Ubungakanani bezansi | 0.01mm | |||

| Ubungakanani bokugqibela komphendulo we-mold | 0.02mm | |||

| Ubungaphakathi lweMould | 30,000,000 amasho,netc.(ngokusho kwaye ngaphandle kwezinto ezaziphakamisela) | |||

| Izinto ezaziphakamisela | Utrimi, iPin, noma uSpring | |||

| Isikhatsi somucabuko | Izithu ezi-3 kwi-6 (izithu ezi-3 yomodeli yeprototype) | |||

| Isiqephu | Indawo yokugcinwa yeWooden Box, Carton | |||

Amathupha wokuqinisekisa zibe:

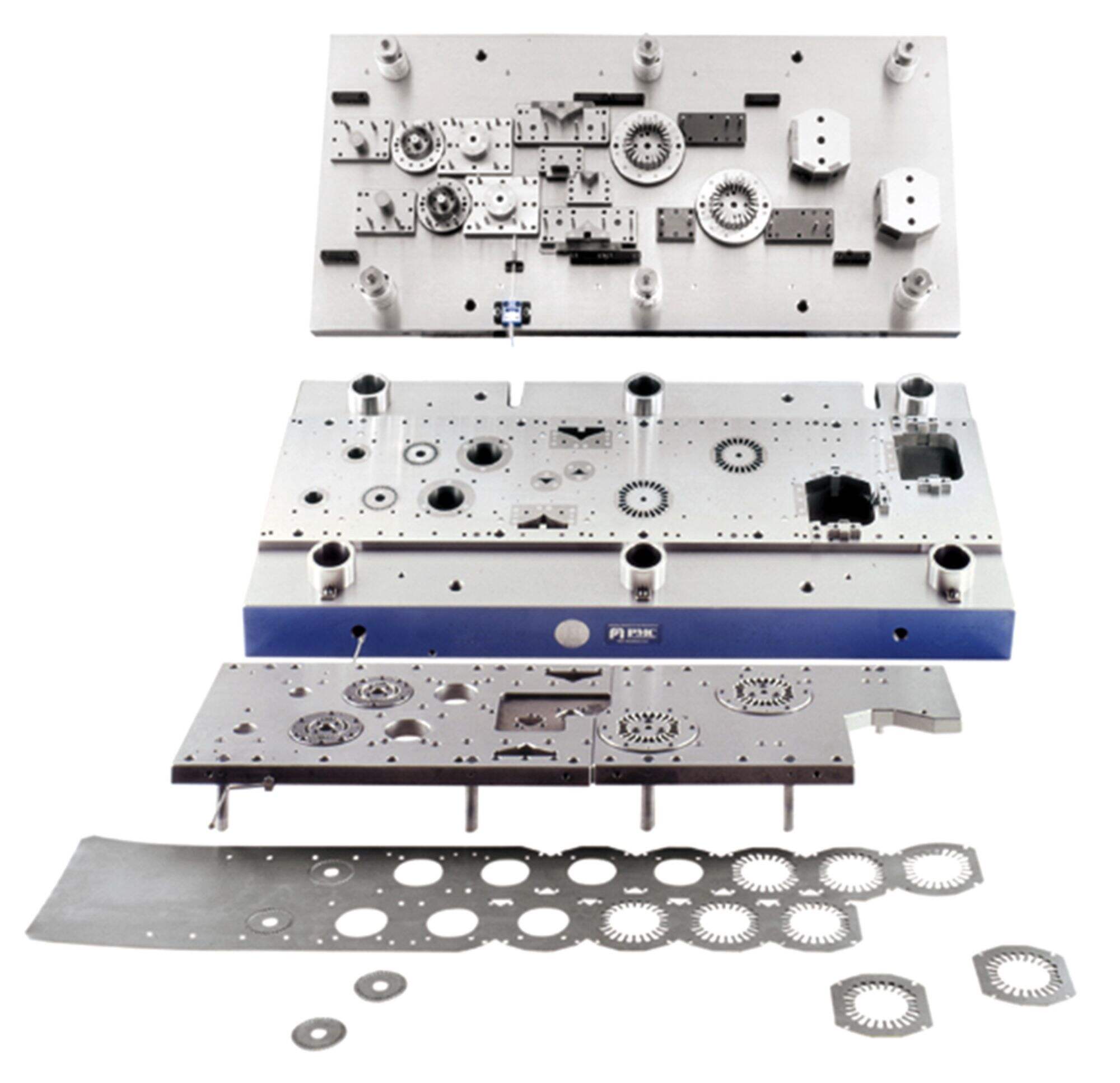

1. Amathupha weBending

2. Amathupha weButton

3. Amamodeli weHole Punch

4. Imibhedi Yemendlalo