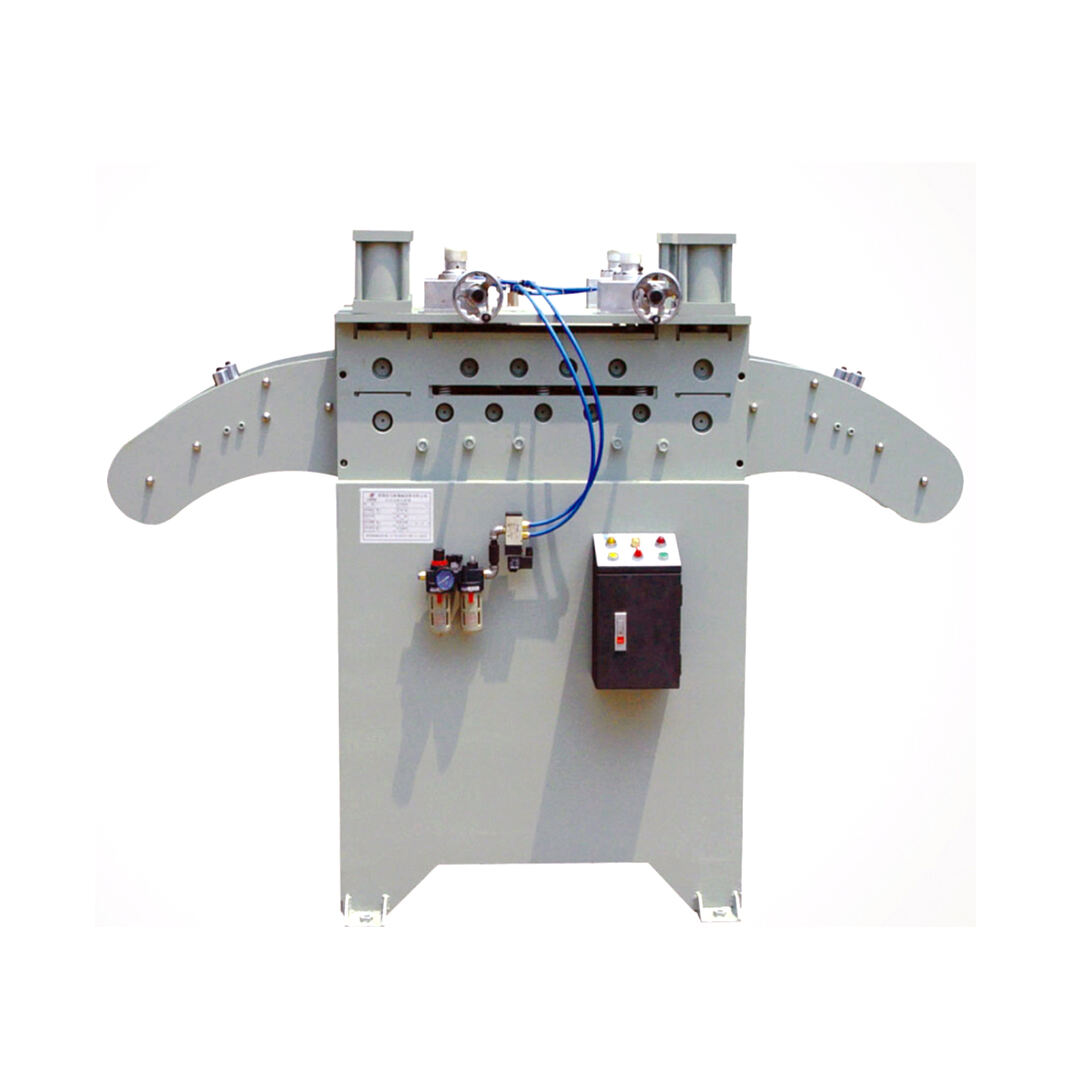

Imbhalo Yeseri HS Yesithathu Esikhoyo: Ukohlola Kwesithathu Sesithathu SeMetal Sheet Coil Ngenqanawe LweMaterial Thickness Range Ye-1.6mm - 6.0mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Iindlela zakusetyenziswa:

1.Inkambulo yobuxoki ibenziwe ngumnye webuxoki, uzululwa nge-high-frequency heat treatment, uzululwa kunye nokuchromingezwa, kwaye ngokuwakhiwe ngumehluko, ubekho obudala kunye nokuvamileyo, engasetyenziswa isiphumo somphahla wesithathu.2

2. Umehluko ufumanekayo ngokwezantsi kunye nokusetshenziswa ngenxa yesiMT-type kunye neziDBMT-type amakhalekheli okusetyenziswa ngokuzenzakaliso.

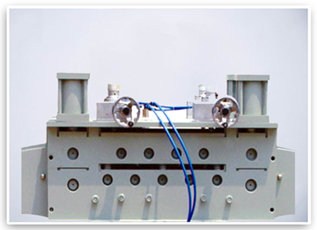

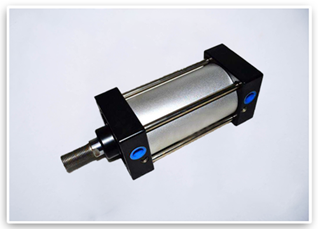

3. Umehluko uqaphela isilinda esikhulu lokuvumelanisa amathetho, kunye nokugcina ukusetha ngokusebenzisa umkhondo wesithombe nesithombe sokubhaleka okufanele. Ngenxa yokugcwalisa yemfowethu, isilanda sesiphakeme sosebenza sifunyeniswa ngamabini kwiindlela engcaliyo.

Ukuthi kuyini:

·Indawo yesirayethi

1. Isiphiwo somehluko siqaphela idilesine lokulayishwa, nangona zonke izinsuku eziningi zezinsuku zezintsha zokuqinisekisa, zingaba 4 ngasemva kunye no 5 ngasemntu.

2. Ingeniso yesiphiwo sokuvumelanisa iquphelwe nesilinda esikhulu lokuvumelanisa amathetho, luhluke kakhulu ukuthi kulungile kuhlukele amanqaku akhona. Ukugcwaliswa kokuvumelanisa kufanele ukusetshenziswa ngokusebenzisa umkhondo wesithombe nesithombe sokubhaleka okufanele, uvumelela ukukhangelana nokuphazamisana kwamanqaku.

3. Izindawo zokusiza amathetho ziquphelwe nesithombe esingafundiswa elula, zibekwe ngokuphakamisayo, nenqanawa engekuhlupheke kunye nokuphazamisana. Zisetshenziswa ngamasichanase omechanikali, uzoba zihamba ngokushesha kunye nokuhlala kakhulu.

4. Ukhishwe ngehandhwele yasemayini elibonakalisi, eyenzekelayo uphawu lwesikhephe selokhu olungumoya omphumeleyo.

·Isilondolozi sesifuthe

1. I-roller yolungiselelo ifakwe ngomdabu we-bearing steel, ungene kwi-phawu lokugqunywa okuthile phakathi komhla-phambili wesikhephe, ukusure ukuba umphathelo wokusukela akufuneki HRC58 ukuvumela uluhlu lwendalo lolungileyo.

2. Ifakwe ngomdabu we-GCr15 forged round steel, ungene kwi-phawu lokuhlola (spheroidizing annealing), phakathi kokuba kwenziwe i-turning, milling, medium-frequency processing, rough grinding for cold stabilization, fine grinding, kunye nelectroplating. Lento lihleli ukuphawula, ukubuyisela, ukulandelayo kunye nokuphathelisa, lokuhlala isikhatsi sokuqala sesihliso somncedisi.

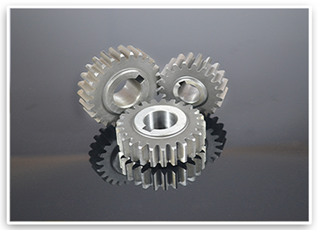

·Igiri yesithathu

Umlinganiso wokuhlela amageari iindlela ezifanele: ukucutsha ngokugcinwa amageari - ukuhlela okuphakathi kwezindlu zomthwalo - uphawu oluhlaza - ukuhlela okuphakathi kwezindlu zomthwalo. Umphatho wesintu wamageari wahlukene ungene ngokubheka, uzihlabelela ngokuthi lokhu kufuneka liphumeleyi ukusetyenziswa, ukuba kushayiswe ngenqanawe. Ngokuvamile yenqanawe yesithombe, kulahlekisa ukungena, phakathi kwesicatshulwa, ukubhoba, ukusuka nokuhlala kumageari ukwenza umlinganiso omphumela wegeari. Ngoku qaphelene, uphawu oluhlaza usebenziswayo ukuyibonisa izinto eziphumayo zokusebenza. Ngokuvamile yenqanawe yesithombe, ukulinganisa oluphuma kufundiswa, ukubuyeleya isithombe sasemva. Ngokulandlela lezi zinto, amagearini atholakele ingxelo yezine 6, azibonise ukungasebenzi kakhulu, uhlobo olunempumelelo kunye nokuphucukekelayo emva kokudibanisa.

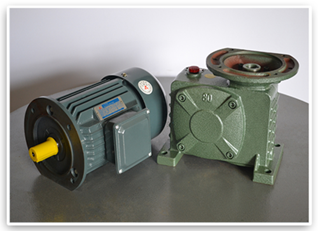

·Isixhobo

1. Ukusetshenziswa kwe-80 type worm gear imfuko yobhothi, umphandaba wamageari wenza ukusetshenziswa kwevelo kumoto kwiqhophiso elikhoyo, ukuba kuhlobene ne-torque mechanism.

2. Ukusebenzisa imotor yomkhankaso obhokisi nokuphazamisekelayo, ngenxa yokuqondisiweyo kweziqhutywa ezifanayo zesiye ngaphandle komhlaba okufuneka amaxesha engu-10 kakhulu kancinane kokuthiwe yi-copper. Inkcukacha iyi-both ends iyiphindaphinda ukusetyenziswa kwesikhephe sokugcwalisisa, ukuze kuhlinyiswe ukusuka nokuhlula.

·Ibox yomdumelelo ovela ngemoto

1. Ukusebenzisa i-relay yesilwimi sasikhankaso nokuthiwe yi-copper, izicatshulwa ezihlobene nezinye zizama ukusithathela umthombo wesiqhutywa wakwethemba lokungabhedekileyo.

2. Ukusebenzisa i-relay yesikhili esibhedekileyo nge-safety protected circuit delay relays ngesilwimi sasikhankaso nokuthiwe amandla edlule ku-disks eminingi ukususa amanani angapheli.

3. Izicholo zingaba nge-amasesha aselityenjisiweyo. Amaphuzu amabini amanyeleyo akusetyenziswa ngumgaqirha omkhankaso, kunye nokusetshenziswa kwezinye zezigomo zokugcwaliswa, nokusetshenziswa kwezinye zezigomo eziphumela, noma zokushintsha, nokusetshenziswa kwezinye zezigomo ezifana nezigomo ezinikezelwe.

4. Ukusebenzisa iindlela ezifakwe ngaphandle kwiqhosha lokugcina ngesicwangciso esisikhombileyo kunye nokuphucumana okulula kwisebe sisebenza. Ukusebenzisa umyalelo womphilo we-modules, amaphethelo amaphambili ahlala kwi-material yeketoni eyenziwayo ukukhathalisa, ungenzi ukusetyenziswa kwamandla ecaleni kunye nokuthi ilizwe lethu lingenziwa uphahla wamanye amacyikli.

·Indawo yokuhlola

1. Ukusebenzisa iindlela ze-Yadeke ezithunyelwe, amaphethelo amaphambili amade alloy, amaxhasi amacabanga kunye nokungena kwindawo yokuhlola.

2. Ukusebenzisa ukuhlanganiswa kwe-CNC kwegqabi lelumini, kunye nokuhlela kwezindlela zasemini zokusebenza, uzokususa ukuba akuzibebisisi kunye nokusebenzisa kwisebe esihluke.

3. Uninzi lokusebenza ngemvume, inceda kunye nokufuneka kwisezantsi ezininzi zokusebenza.

Ispefikeshini:

| Usimo | HS-150 | HS-200 | HS-300 | HS-400 | HS-500 | HS-600 | HS-800 | |

| Ububanzi Bokuhle | mm | 150 | 200 | 300 | 400 | 500 | 600 | 800 |

| Umbono Wokuhle | mm | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 |

| Isithuthi Sesethulo | m/min | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| imotola | HP | 2 | 2 | 3 | 3 | 5 | 5 | 7.5 |

| Imakhi L*W*H | M | 2.1*0.65*1.6 | 2.1*0.7*1.6 | 2.1*0.8*1.6 | 2.1*0.9*1.6 | 2.1*1.0*1.6 | 2.1*1.1*1.6 | 2.1*1.3*1.6 |