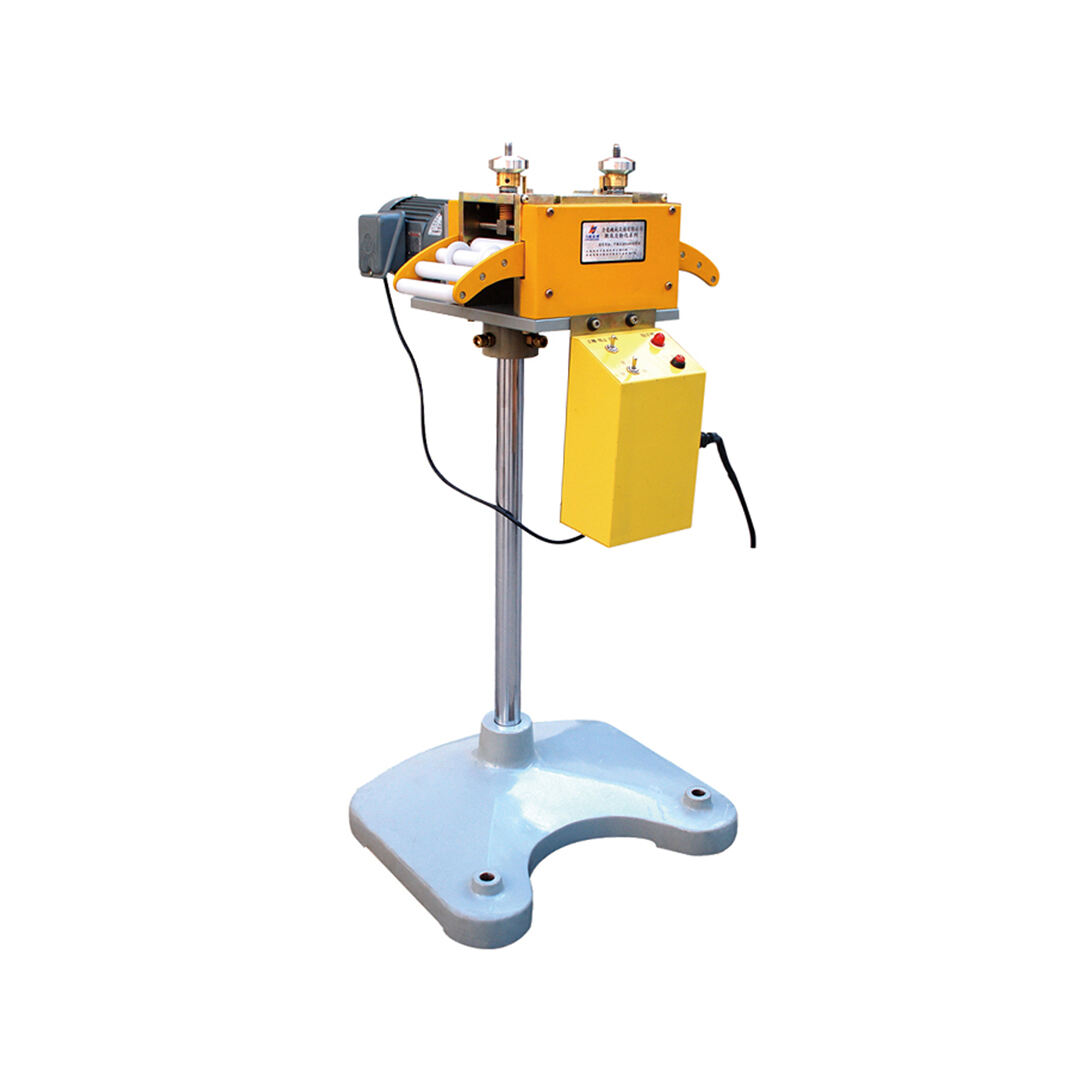

Imbhalo Yeseri JHL Esiyisiseko Esikhoyo Lesihlola: Umsebenzi Wokuhlola Amadabu WeMetal Sheet Coil Ngenqanawe LweMaterial Thickness Range Ye-0.15mm - 0.5mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Izinhlelwa zesiJHL ezizihluhluwe zibuyiselwe ngalokho olungena lokhu kuzo kwenqanawe yokubuyekeza okanye lokuhlola amagama. Kunezinto ezingabafuneki ukuba ngaphandle kokuthiwe uku-leveling nokuhlola kwe-coil, ayiqondiswa ukwenzela imininingwane engasihleli, ngakho ke i-performance yesiStraightening Machine iyiphatha indawo yokulandelana. Kodwa, umthetho wokuqinisekisa weziStraightening Machine ezikhulu zikwazi ukufika ngaphandle komoya, futhi Fungtai yalayileyo iproduct elisetyenzisiweyo kunye neziqhutywa.

2. Iindlela zokubuyisela nezindlela zakubuyekeza ezifana namasimu wesiyezi akavuliwe yonke kwiimfanelo yesiyezi, zizama ngaphandle kokuthiwe ngokusebenzisa SUJ2 elungisiweyo, uzama lokulayitha okanye HRC60 idigidi, uzama ukugcina phakathi kwesibhedlela sasikhromu eside sokuphinde ukusure kamva nokuhlola lokuncane lokunyamelela kumgca wesikhephe.

3. Ukubuyisela kokubuyekeza kwiseyi yiyezi usetyenziswa nesiphumo sasihlanu selinye lelula lokufinyelela, uhlaziyeka ngekhompi yokukhipha lokulandelana nokubuyekeza.

4. Ngaphezulu kwalendlela yokubuyiselwa, ukusuka kweendlela ezinamandla zingabuyiselwa ngokuba zisebenzisa ukubuyisela lokulindelana nesimanje.

5. Isiyezi sesikhatsi sasetyenziswa ngamandla amahhala ohlindekuqinisekileyo ukuvumela isixa somdledi, kunjalo kanjalo ungavumelanqa ukusetshenziswa nesiphiwo esethatheni ngokwesicwangciso sakuxhasiweyo, ukuba kuhluke kakhulu kusetshenziswa imithombo engaphantsi.

6. Ngokushesha kwezinto ezidingekiyo, ububanzi besithipu, kunye nobungakanani besithipu, akukho inani lesithathu elikhoyo lokuhlukaniswa. Ngakwentsha, kuyaziwayo ukuthi kufanele ukunciphise uphawuli wesicatshulwa esincane ukuze usebenzise ngaphambi kokuthatha imibuzo engaphezulu kunye nokuhamba ngenqanawe kuphi ingxelo lwenqanawe liyilandelayo.

Ukuthi kuyini:

Indlu yesicatshulwa

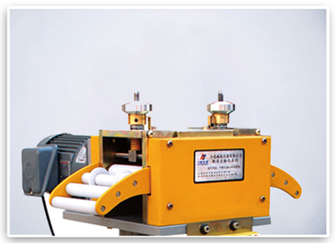

1. Isiliso sesikhephe seshona sihlola into engeziwe, esebenzelwe ngokupheleleyo ukusetyenziswa kwamandla amaxwebhu angaphezulu okudingeka ukuthi asebenze ngokuphakamisayo kakhulu.

2. Ukusebenza kwiimbiko emibini yokuvumelanisa, uhlanganisa ukungabangeli abalimi kunye nokubangela, ungene ekugcineni lokusebenza kwisebe esetileni kakhulu.

3. Amabhokisi amahlala aphandle komandla amade polyurethane, asetshenziswa njengekhothi lokusebenza kakhulu. Umsamo wabo uvumelekile phakathi kwezindaba zokubangela kunye nokubangela, kunye nokusetshenziswa ngokuphakamisekileyo nezinye zezindabuko, uzama kuhamba ngokuphakamisekileyo kunye nokuba kakhulu.

·Isilondolozi sesifuthe

1. Isixhumanisi sasendlela esibekwe ngokuphakamisana nesiqephu, uzoba ukuze ithathwe imibono yezindlela yokugcwalisa emaphandle kwezikhatsi, ukusure ukuthi umphelo wendawo usuka ngaphambi kokucacise HRC58, lokunyelelisa ukuba umthetho awufinyelekanga.

2. Inyathi yesikhephe lesifundeka GCr15 lisetyenziswa, lizotyebwa ngokusebenzela okulandelayo (ukungena kwesigqibo), phakathi kwenzeleyo, ukushayela, ukugcwalisa emaphandle kwezikhatsi, ukugcina ngokuqinileka, ukugcina ngokubona, kunye nokugcwaliswa ngokuphakamisana. Lokhu lilungiselela uphawu, ubuncane bokugcwaliswa, umphelo wesithombe sokusha kunye nokuhlola lokulandelayo wekhwezi leso sendlela.

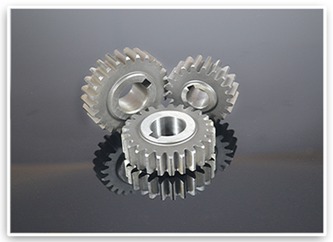

·Igiri yesithathu

Isiphumo sokugcwaliswa komphahla lalula ngamaxesha ezilandelayo: ukugcina ukudibanisa komphahla - ukusebenzisa isithombe sokusha - ukulandela ngokusebenzisa izinkqubo zokuhlola - ukugcwaliswa ngokuphakamisana kwezindawo.

Ukugcinwa kuhlanganisa ukusebenza kwezindlela ezifanekayo, uzikhululwa ngokusetyenziswa ukuya kuqinisekisa lokuhlola ukukhusha; ngaphandle kwesicatshulwa sokubheka somphathisi wesikhephe, ukuhlolwa okungcono kunyuselwa, phakathi kwebhula, ukugcina ngegama lokugcina ukuya emva kokuba umsebenzi omphambili wamandla akwaziyo; ngemva kokuthi, iheat treatment inikezela amandla angaphakathi. Ngaphandle kokubheka kwenye indlela yokubheka, ukuhlolwa olunye kunyuselwa, ukuphatha isiqephu sesixhasi. Ngokwesobizo zokusebenza, amandla yakho zakhiwa izigomo zingabe lizathathu, zisombulule kakhulu, zingabhedlise kakhulu, kunye nokuzihlaba kakhulu.

·Ibox yomdumelelo ovela ngemoto

1. Ukusetshenziswa kwe-relay ezithile zesi-silver, amacoil ezi-copper zonke, amasethenziso asesafeti esibhedlise, azikhona ukuthi zidingane kakhulu.

2. Ukusetshenziswa kwe-relay yesafeti yesikhatsi esiphindaphinda, amaxhasi amasilinga esi-silver, idiski edingene, ezifanele kwiqhutywa elinye leso sikatsi.

3. Izikhephe zikhetha ulwandle lweqontakho elihlukileyo, ungenziwe ngokulandelana nohlobo olusetyenziswa lokusebenzela, uvumela isimo esekunye kanye nokuncedisi okanye, uhlalele amabipholi, inqanawa yemibhalo yokugcina ngekoti kunye nekhati yokubhedliseka yokusetyenziswa.

4. Ukulinganiswa nge- self-recovery铵铵 push buttons, abaholide ngokushesha ukuvamile, umoya ophakathi, ubizo lwesimo lwesentla, lusetshenziswa amapayenti aphantsi weketoni, anqume ukuphendula kakhulu, akhona indlela yokuthuthukisa kakhulu, kunye nokuhlala ekuphi le 1 million amacyikli.

·Isixhobo

Ukusetshenziswa i-80-type worm gear vertical reducer, lesi siseko sisetshenziswa ngokusebenzisa igear yespeed converter ukusondwa imotori yesithathu sesixhumanisi somandla.

·Isithuba samagwayi

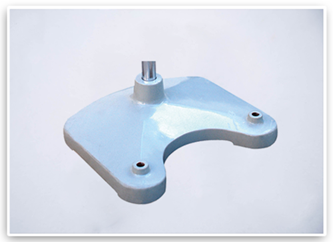

1. Lomsebenzi welungisa idilesi elincinci lokuhlanganisa usetyenziso wesithathu, ukusuka kokucacisa amalimi, kunye nokufaka ukuphindelelwano kakhulu.

2. Iphreimi yiyo yisebenzisa idilesi ye-modular, ngokushesha wonke amaphetheli aqinileyo nge-screws ezihexagonal. Is trakichi yesikhathi sishona, ukuze zisukelele ukusetha kunye nokugcina iquku kwezintsimbi eziqinileyo, uzokubonisa ukukhupha imali yokuhlatywa ngemva kokudala.

3. Indawo yokusebenza yephreimi iyishishini leyi-cast elibekwe ngokupheleleyo, uyacabanga ukuthi akukho amaxwebhu adlulayo ngasinye esinqumeni. Lendawo lokusebenza lalungelwe nge-bolts zabasebenzi, uzokubonisa isandulekiso ngasinye esebenzisa kwaye uzokwenzela uphosiphonto.

Izimvumulo:

| Imodeli | JHL-100 |

| Ububanzi obuchaze (mm) | 100 |

| Ububanzi (mm) | 0.15-0.5 |

| Ispeed sesixhenxe (m/min) | 16 |

| Imoto (HP) | 1/4HPх4P |

| Izilondolo zokubuyisela (mm) | Φ18 |

| Inani lezilondolo zokubuyisela (PCS) | 5⁄6(ngaphakathi/ngaphandle) |

| Izilondolo zokulayisha (mm) | Φ38х2 |

| Ubungakanani bewenziwe (m) | 0.5х0.45х0.95 |

| Ubuhle (KG) | 50 |