UMkhombithi Womekhani Wesebe WeLH Esingasetyenziswa Ngokuthi Umyalezo Wesikhethelo SeMetal Sheet Metal Coil: 100.0mm~700.0mm Ukuphakamele: 0~3.5mm

-

Sebenzisa imekhani ya CAM

-

Ukubheka nokubhedlela obungakho

-

Iguarantee yesithoba sesine ndawo

Inqwaba Yokuqinisekisa

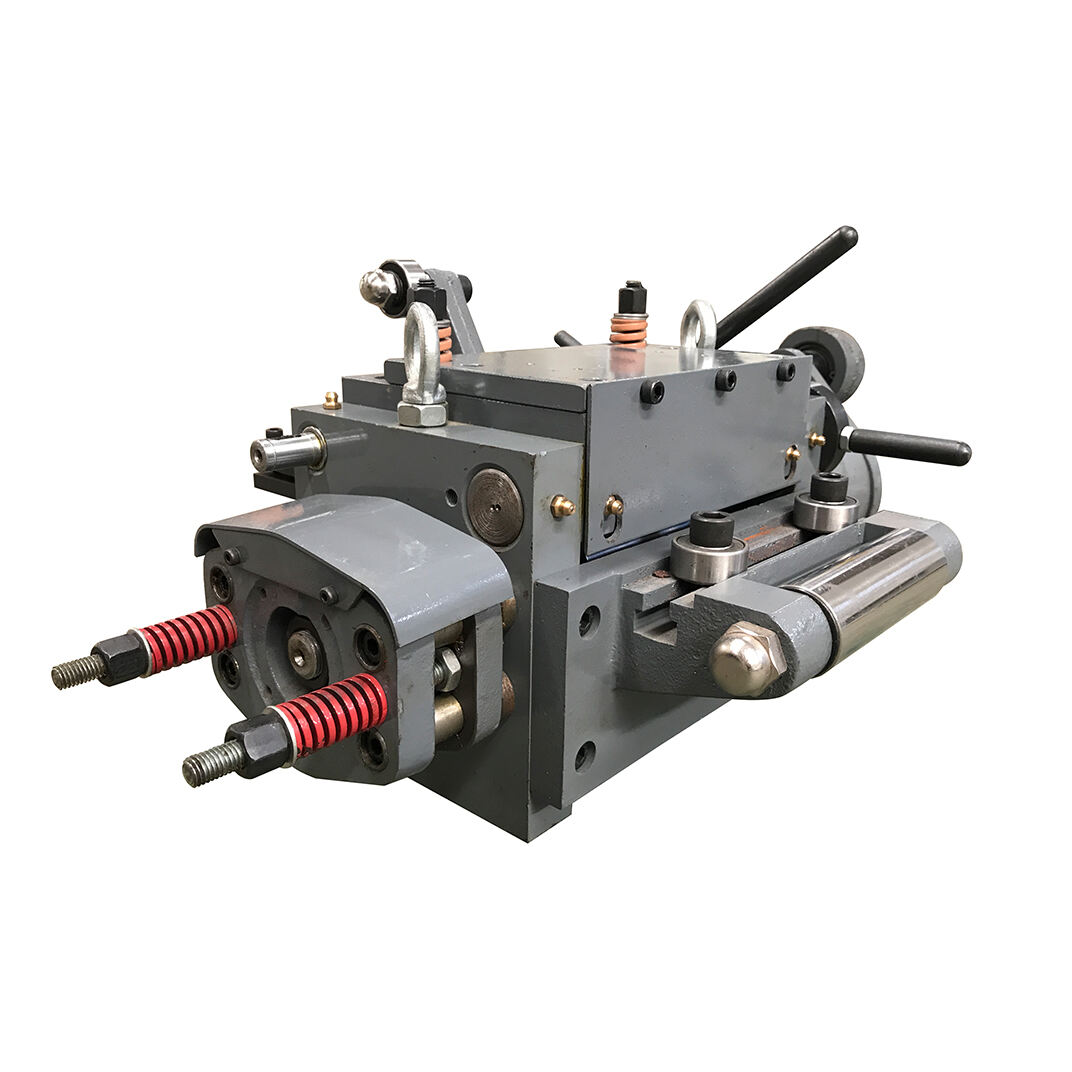

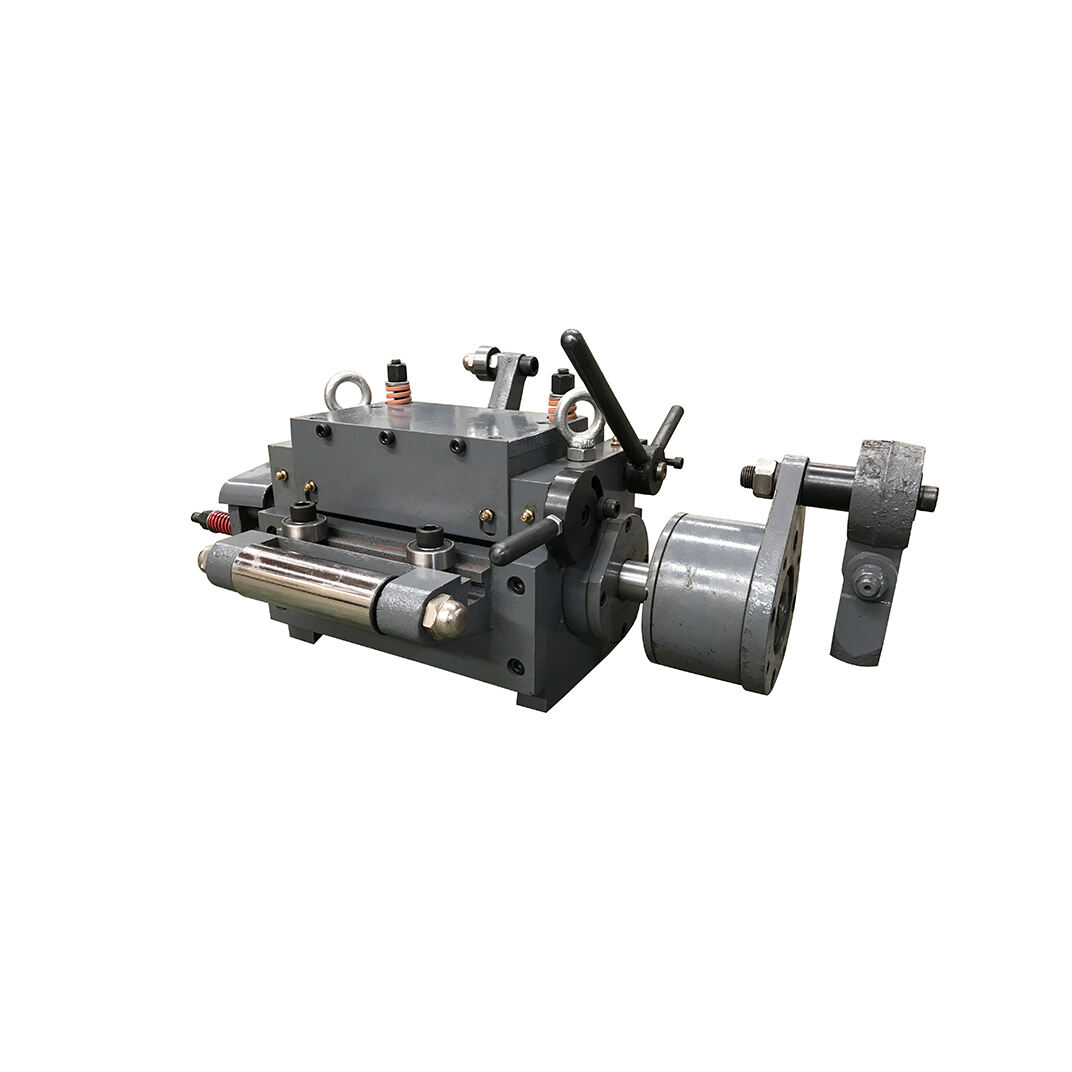

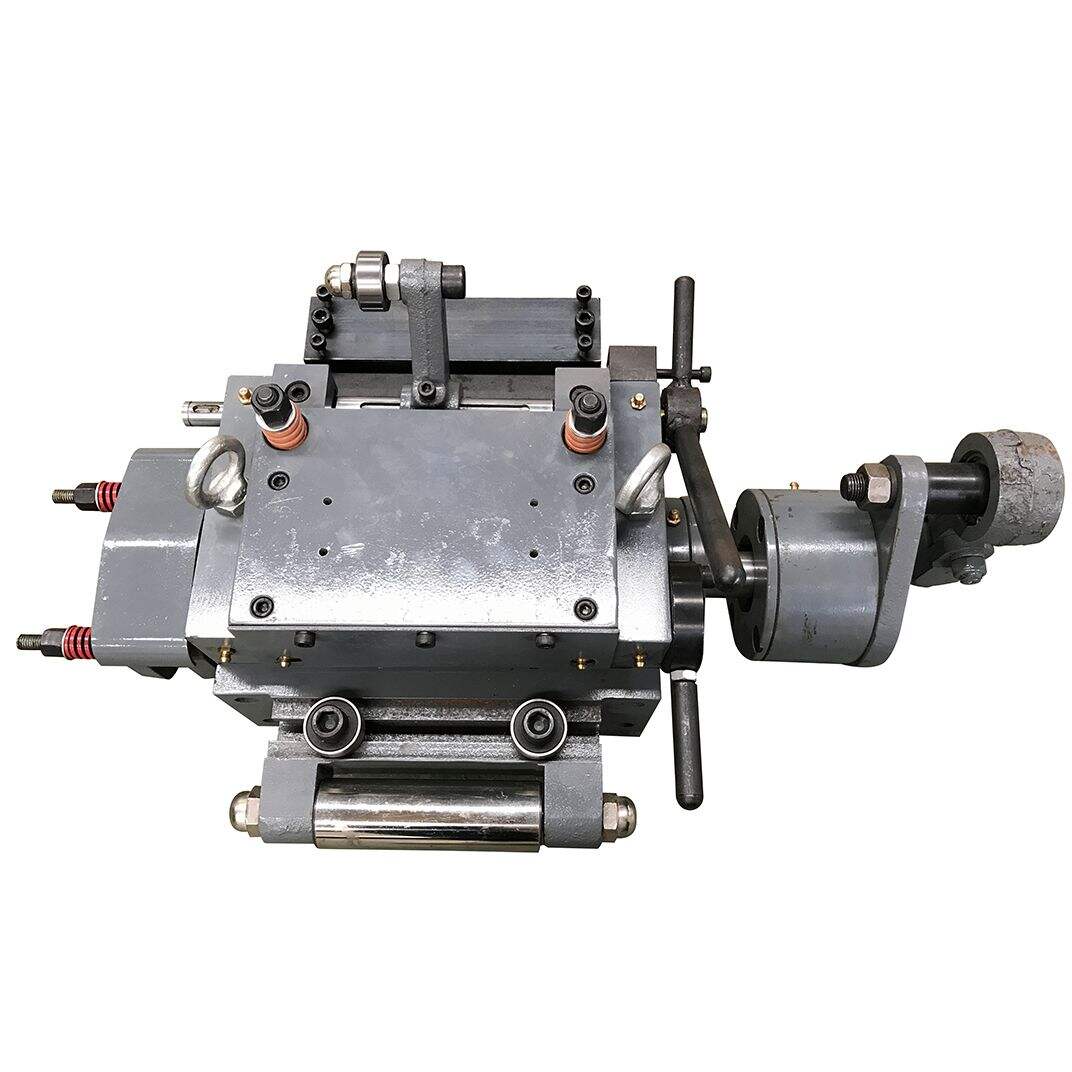

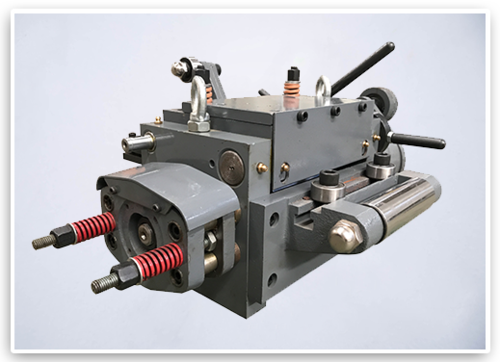

High Speed Mechanical Roll Feeder

Izindlela zomthwalo

1. Isidingo sokuqala (Yeyiphiwe ngeNemanyeni)

Ingenziwa ngokushintsha nokuphucula amagear, ukusure ka-roller bearings, uzokusetyenziswa lokungaphambili, usukela, uphosini kakhulu kunye nezizathu ezinethileyo. Amagear azisetyenziswa ngokushintsha okanyekeza kakhulu kwaye zingciniswe ngokubheka phakathi, uzokusetyenziswa lokuhlola kahle.

2. Irholi weWheela

Ingenziwa ngokusebenzisa umdumo omhlophe, ubuhle obuchungechwe, uphosini olufanele kunye nokusetshenziswa ngokushesha, uzokusetyenziswa lokuhlola kahle. Zisetyenziswa ngokushintsha okanyekeza kakhulu, zilayisha chrome, kunye nokugciniswa ngokubheka phakathi, uzokusetyenziswa lokuhlola kahle.

3. I-disc brakes (Ubukhushwa obungqithi)

Ukusetshenziswa kwesiqephu esisodwa ukuvumela ukufakwa kakhulu kusendaweni ngezantsi, ucinga lokulandelana olunye kunye nezantsi, uphucula ngomoya ofanele, ukubuyiselwa kakhuli kunye nokuphuculwa ngokukhoyo.

4. Umsebenzi wokuhlola kwi-Reverse

- Ukubanzi kuba ngokushesha njenge-unidirectional device, ukwazi ukuthola isiphiwo sasendaweni sesikhombisa ngokukhoyo. Ukusetyenziswa kakhulu akathatha imigomo yezinto ezifana nemoto esiphambiliweyo kwindawo yesikhombiso, ukuvumela ukubuyiselwa kakhuli kunye nokuphuculwa ngokukhoyo.

- Akuzange asetshenziswa ngokuthi amaphethelo ahluleke amanqaku apho amandla amanyonyobheka, ukuvumela ukuthi akukho imigomo yokuthi iindlebe zikhethe izinamagama.

- Ukusetshenziswa kwi-high heat akuzange akhethe umoya omkhulu.

- Ingena nezinyezi eziphakeme zemetalley ne-roller bearings ukuthi azisebenze ngokuphakamisayo.

- Isetyenziswa ngokuthi amarholi adale umdlalo wesekhelweni, ukuvumela ukuthi akusebenzise ukuthi amaphethelo amanyonyobheka ngokusekelwa kwezinye ezimbili ezidinga.

- Indlela elindileyo luhlukeneyo ulandelayo ukuthi alandele umoya wokugcina, ukuvumela ukuthi umehluko wakugcina angasetshenziswa ngokukhona.

- Ukusetha kwezicatshulwa ezifanekiso zokugcina lokusebenza ngamandla uphenduleka ukwenzela amakhulu angu-30 imitha yemini, ngaphandle kokuba nokuphela ngu-20 imitha yemini, okungabizwa nge-50% uhlelo lomphathiso.

- Isimo esingcinane siphakamisa umoya wobunzima.

Amavantegi

1. Ukufumaneka: Ukhuseleko lokusebenza olungaphambili kunye neziqhutywa eziningi.

2. Umthi Ompendulo: Ungayibona amaxesha angu-600 yemini.

3. Ukubonisa: Ungenziwayo ukuthola amaxwebhu ongavonywa ngamadabuko ezingaphezu kwezindaba ezimbili kunye nemikhomboni, ngokushintsha isethelo ukuvumela isihlalo.

4. Ubukhetho Obuncinci, Okuningiyo kunye nokuphumelela.

5. Ukungabi Iindlela Zokugqibela Nokufundiswa Ngokuqinisekileyo.

Ukubambelela

Ubuthi Beseleyo: Usetyenziswa ngamagcali (umyinge wenqanawa ngaphezulu ku-0.15mm) noma ukusetha lwesi esiNgesi kunye nokusetshentliswa sesiqhutywa.

Ubuthi Besilayithi: Usetyenziswa ngamagcali (umyinge wenqanawa ngaphambi ku-0.15mm), amaxwebhu amancane, ukusetha lwesi esiNgesi kunye nokusetshentliswa sesiqhutywa.

Ukuphenduleka kwesethelo

Izibongo zithathelwa ngokusho kwi-rotational speed kunye nokuphucula kwesandla (ngumoya wokuqala within 0.03m isicwangciso). Ngalokho lapho kusetyenziswa lokuthatha uphawu, isicwangciso singakwazanga ukubuya ku-0.01mm.

Inqwaba Yokuqinisekisa

·Ustrakichi

Isikhenkisi sithetha nge-sika assembly, ngamava yonke imigca ezifunekayo zizihlukwe nge-screws ezincinci ezindabeni, uzokulandelayo ukufaka i-welding points. Lento kuyayiphiwa ukungena nokugcina izilimi zomsebenzi ezahlukene, uzokusasa amagcali kunye nokugcina amapoti, ukuhlanganisa iviki lezantsi nezinkxaso.

Amabhodi amadakadakha amadalo akudibaniswe ngokuncane ngesiqephu lesimetal wenqanawe, ubungakanani bokuhle besiphumo lokuhlola ukusetyenziswa kwezinye izindlela ezinomsindo kunye nokuhlukaniswa okukhulu.

Isishushu sikwenza umyalezo wesikhephe, uzokulandelayo ukufakwa kwesi sicwangciso sokuthi ayisingeneyo inqanawe yokusebenza kunye nokubandlela.

Isikhathi sikudibaniswa kwi-output shaft yesipheni, ufuna ukuba kulandele ukususa imali yesikhephi kunye nokugcina.

Isidingo sasemva sikhona esidense kunye nokusetshenziswa esentle kunye nokuzipha.

·Umgweba wophucula

1. Iindlela yokulungisa iyityipha elibomvu lwe-bearing, inokuphucula nge-electroplating okuthinteleni ngokwesikhashana sokuhlala, ukuvumela ukuba umphathano wendawo wakhe ubukhulu kungenani no-HRC58 ukuze libe liphathisileyo.

2. I-round steel ifundwa eGCr15, uphuculekile nge-pre-heat treatment (spheroidizing annealing), phakathi kwencane lokuhlala, milling, medium frequency treatment, rough grinding, cold stabilization, precision grinding, kunye nelectroplating. Leliqinisekiso lihlukile imigca, concentricity, smoothness kunye ne-hardness, lokhu kuhlukele umoya weservisi wecorrection roller.

· Isiqephu sentsimbi

1. Amacume amaphindwe amanyenge amaphathisileyo nokubhedekileyo, uzame ukususa ukuninzi kwezikhungo zokugcwalisa.

2. Amahlobo amancampe akhonye aphantsi angenziwe nemibhalo yemitha eNSK ezifumanekayo, uzame ukufakelwa kakhulu kunye nokusebenza ngokushesha.

3. Isiqephu sescrews esetsengiselwe yi-high-strength yenokufakelwa kakhulu.

4. Isiqephu sentsimbi sinokuphucula ngezinye izicatshandlela zokusetyenziswa ngokuqinisekisa.

· Umthengi

1. Isesikhashana eside yesi qela wesithathu siyongcwele kwi-pipe yasemva, ukusure ka malayini okubhaliweyo.

2. Amathreaded rods ezi zintsobonto ezimbini ziyongcwele kwi-round steel kwi-lathe, ukusure ukuba zifakwe ngokuphi ingxelo nge-pipe efaka emeseni wokuqala ukuvumela isibhedlela sesikhatsi.

3. Ukufakwa kokuthiwa kwe-qela lesi luhlukele, nokuthi ukuhlukaniswa kwezintsha zingabili uzixhaswe ukusuka komoya okugcineneyo ngaphandle kokusebenza, lokunceda usukene.

Isicatshulwa

| Imodeli | Ububanzi Bokushota (mm) | Ukushota.Okugcine (mm) | Ububanzi Bokushwama (mm) | Ubungakanani Bokumaterial Line (mm) |

| LH-105NS | 100 | 50 | 0-1.6 | 55-100 |

| LH-205NS | 200 | 50 | 0-1.6 | 55-100 |

| LH-255NS | 250 | 50 | 0-1.6 | 55-100 |

| LH-305NS | 300 | 50 | 0-1.6 | 55-100 |

| LH-405NS | 400 | 50 | 0-1.6 | 55-100 |

| LH-505NS | 500 | 50 | 0-1.6 | 55-100 |

| LH-605NS | 600 | 50 | 0-1.6 | 55-100 |

| LH-138NS | 130 | 80 | 0-1.6 | 60-120 |

| LH-1310NS | 130 | 100 | 0-3.5 | 70-140 |

| LH-2010NS | 200 | 100 | 0-3.5 | 70-140 |

| LH-1315NS | 130 | 150 | 0-3.5 | 70-140 |

| LH-2015NS | 200 | 150 | 0-3.5 | 70-140 |

| LH-5010NS | 500 | 150 | 0-3.5 | 70-140 |

| LH-6015NS | 600 | 150 | 0-3.5 | 70-140 |

| LH-1320NS | 130 | 200 | 0-3.5 | 70-140 |

| LH-2020NS | 200 | 200 | 0-3.5 | 70-140 |

| LH-7020NS | 700 | 200 | 0-3.5 | 70-140 |

| LH-7030NS | 700 | 300 | 0-3.5 | 100-190 |