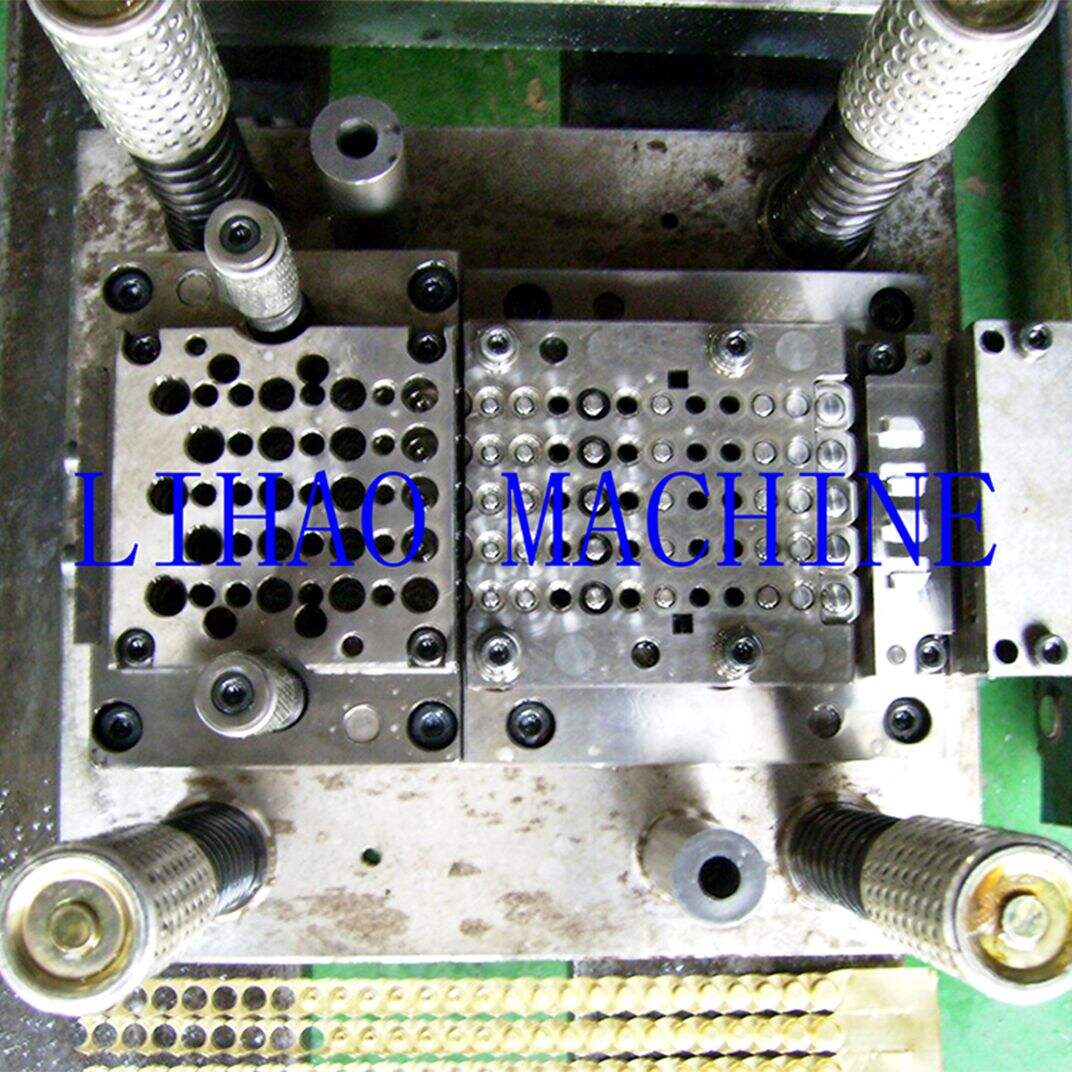

Metal Stamping Mould progressive stamping die Punching Die Press Mould Deep Drawing Mould Press Tool Die Sets

Inqwaba Yokuqinisekisa

Izixhobo

1. Ukusetyenziswa kwiqhutywa lapho amaninzi okanye amagama apho amaprodakhti aphantsi awusetshenziswa ngokuphambuka, amaprodakhti aphantsi anasetshenziswa ngokubanzi kwiindawo zokusebenzela ezilandelwayo, nge-mobilini, tooling, commodity, nokulandelayo.

2. Ukhuthele ngokushesha ngokubanzi kumashini wesintandza esikhulu esetshenziswa ngamashumi amabili ngamavoti (SPM) ngalanga elishumi lokusebenza. Ngenxa yalokho ukusetshenziswa kwezihlobo ezinhlanganekayo ngokukhipha imibongi nemashini yokukhipha ngokubanzi, isebenza ukugcina uhlobo lweprodakhti lokusetshenziswa phakathi komhlaba kunye nokuthatha umdlalo wendawo, futhi ukuseta ukuba zisetyenziswa ngokubanzi ngokungafuneka zisetshenziswa ngamanje. Lokhu kuzifuneka ukususa izindlela zokusebenza, futhi ukusuka isithelo sokusebenza.

3. Ukuthi uzisebenzisa iimateriali eziphumaphuma ngokuqondile kwe-10%.

4. Ukusebenzisa okumakaza kwezilondolozi nesithuthi esethelayo ngokwesobizo kuhlanganisa isenzo sesikhathi nokulula amalayini.

5. Iindlela eziningi zinakubizwa ngokuphelele kuqhawekazi ukusetyenziswa kwamathathu, ubungakanani nobuciko.

Amagama amatekwana:

| Inqwelo Yomdlobheni | Imandla yeshintsho sometalu | |||

| Isopho esideyisayo | ProE, CAD | |||

| Iphawuli | Uphawuli olunye ,Uphawuli olungaphezu | |||

| Umthombo wematerial weMandla Engxenyeni | SKD11 | |||

| Umthombo wesihlobo sematerial | DC53 | |||

| Ipin yaseLeader Bushing | Ukuphakama kakhulu | |||

| Ukuphatha kwePunch | Ukulungisa ngokubenza kwiCenterless | |||

| Ukuphatha komphendulo wemold neinsert | WEDM-LS | |||

| Ubungakanani bezansi | 0.01mm | |||

| Ubungakanani bokugqibela komphendulo we-mold | 0.02mm | |||

| Ubungaphakathi lweMould | 30,000,000 amasho,netc.(ngokusho kwaye ngaphandle kwezinto ezaziphakamisela) | |||

| Izinto ezaziphakamisela | Utrimi, iPin, noma uSpring | |||

| Isikhatsi somucabuko | Izithu ezi-3 kwi-6 (izithu ezi-3 yomodeli yeprototype) | |||

| Isiqephu | Indawo yokugcinwa yeWooden Box, Carton | |||