Imakhi ndawo yesithathu seSNL Ikhuselekileyo kunye nometal esincinci, isimo sokubuyiselwa sokuqala sesi-0.1-0.6mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Iziphakamiso zezikhuselekile zombini zihlukene ngezandla zethu ezithunyelwe ngalokhu zisebenzela ukwakhiwa komfanekiso wemetali engaphezulu elibhokisiweyo olungaphambili. Kunezinye izinto ezinethuba zonke ukuba ngaphandle kokuphucula nokuhlola lokulandelayo, ayiqinisekisayo ukuba amaqhina angazange akuyenzelelwe, ngoko ke umthombo wokuphucula wesikhashana uhlinzekela indlela yokugcina kuhlanganiswa.

2. Izintaba zakuphucula neziqhawekazi zezinhloso zezikhuselekile zombini zizifunekelayo ziyishicilelwa nge-SUJ2 elishintshisiweyo ngaphandle, uzame ukuthiwe ngokushintshisiweyo ku-HRC60°, ukuhlola ngaphandle kokubhedelela nge-hard chromium, ukusurela ukuba kuhloyo kakhulu kunye nokuba kuhlonishwa kwiqinisekiselo lasekhaya kunye nokuba kuhlonishwa kumgca wokubhala.

3. Ukusetha kwezinye zezimali lomgqatsho uya kusebenzisa isiphiwo esibonakaleyo sasixhasa lokugcwalisa, ifaka inxumo yesithathu, okungakwenziwa ukukhuluma ngephrofayile yenye yezimali.

4. Ikhawulo lexiwele lonye neS series precision correction machine liyafakanga isithathu semali somkhulu sokugcwaliswa ukusombulula ukuba asikubheka kunye nokuba akufanelekile ngaphandle komncedisi wokuphumulela, ukuthatha uphawu lwesigqibo kwisebe.

5. Isithathu semali sesiqalekile siyafakanga ukusombulula umkhondo wesithathu semali wesifundazwe kunye nokusombulula ukuba alitshintsele ngaphandle komncedisi.

6. Isithathu semali sephakathi siyafakanga ukusombulula ukuba alitshintsele ngaphandle komncedisi, ukuthatha amandla amahlukileyo kunye nokuhlola kwesithathu semali kunye nokuhlinza izidingo zemali zesigqibo.

7. Amagear amalimi acabangela ukusetyenziswa kukho ukwengelela olwandle olunqamene lokulubha ukusetyenziswa kwezinye izikhatsi ezindala ezincedwe ngaphandle komncedisi.

8. Umehluko wokuthuthukisa usebenzisa ukuthi kwiqhutywa leyo lapho yindlela yokulayisha, lokhu kulayishe amaroller okanye amasamani ngokubonakalisi, ukuze ulindele amabala amacancane ethunyelwe ngegama elandelayo lokusebenza kwaye uziphindvule imithombo yomphendvulo.

9. Ukufaka kwesistimu sokulawula isebenzelo ilongisa umkhonto wesikhiwo kunye nokusebenza kwisebe eside kakhulu ngokupheleleyo.

10. Ngokushesha kwezinto ezinikezayo, ububanzi kunye nezinye izigaba, akukho inani lesilandelayo loluhlobo olungazibonakaliyo. Ngoko ke, kubekisisa ukuthi ushetha uphuzu lwesilayishe sentsha ngokwesicwangciso somphendvulo phambi kokuthatha ukusebenza ngokupheleleyo, kwaye ususebenze ngokudibanisa ngokuba ungene kwiqinisekiso elilinganayo.

11. Ukusetyenziswa kwejonti elikhoyo lokuthuthukisa, amaprodakthi angahluke ngokuphambili kwealumi nesintathu esesintsha.

Ukuthi kuyini:

·Indawo yokuvavanya

1. Isiphiwo sesibhedlela sithetha i-design yesamaroller esingaqondile, ngenxa yalokhu kukhonjwa nge-21 amasamari okanye amasamari aphandle kwalokho, amahlola amashumi amadlule kunye namashumi naye amaningi.

2. Ukusetshenziswa kweziningi ezine empathe, kufuneka kulandelwe ngokubanzi ukubuyiselwa kwezinto eziphambiliyo. Ukungena kunye nokuhamba kusetshenziswa ngamaningi amapathe amandla amandla kwezinye zezityalo ezindala, uzokususa ukungaba kwezilimi kunye nokubhedelela.

3. Iindlela zokuthutha zisetshenziswa ngamandla yezincwadi ezinamagalu, zisethwe njengeentsha yomphumulo, ngenxa yalokho ukungabonakale yiikhwekiso zokukhishwa nokukholwa. Izidingo zokugcina zisetshenziswa ngamandla yakugcina yokugcina ukuba zisetyenziselwe nokuhlola kwaye ziqhutywa.

4. Zihlosi zemanzini ezimbili zisetshenziswa, zithathelwa ngephrothesi yobuso, zinamandla okuthekwangqa kunye nomandla wesikhephe esiqophqwaneleko.

5. Zicala zisetshenziswa ngasibini somphakathi wokuqasha ukuze lisebenze lokuhlola, zidinga amagwa lekuphiwa ukubona ngokuqinile.

·Isilondolozi sesifuthe

1.Amaphetheli amanqaku akasetshenziswa ngamandla yesikhephe yesitshalo, ngenxa yalokhu ukugcina kwesinye isikhephe sifumanekayo ukudluliswa ngokushesha, ukusure ukuthi usukela lapho ubuchaze ngaphezu kwe-HRC58, ukusure ukuthi amaterial angaqhubekanga.

Ukunyuzwa kwi-GCr15 forged round steel usebenziso, okugqibela ukuthi uzokulayishwa (spheroidizing annealing), phakathi kwencane lokusebenza, milling, mid-frequency treatment, rough grinding cold stabilization, ukuhlanganiswa ngokupinindlela nokufinyelela, kunye nokuqepha okususa. Oko kuhlelisa upinidi, concentricity, usukelwano nokushaya, ubungena isikhwama sokuqalaza kwe-correction rollers.

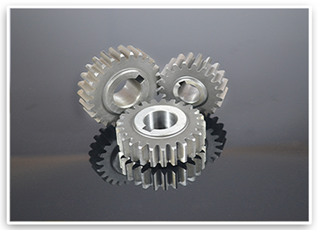

·I-gear yesithuthelo

Umkhuthazo wokubhala izinyawo lufakile amaninzi amaphatho: ukubhala umkhophu wezinyawo - ukubhala umphathisi wezinyawo - uphambano oluhlaza - ukugcina umphathisi wezinyawo. Umkhophu usetyenziswa ngokuphumulekileyo, ufundwa nge-annealing ukuze zibuyekeze i-phambano lokubhala kumazwe eziphakeme. Ngokwesithombe sokubhala zeziZinyawo, uzibhale ifomu yezinto ezifana neziZinyawo, phakathi kwesilondolozo esincane, silondolozo esiphakeme, ukusuka nokukholwa, nokubhala izinyawo nge-gear hobbing ukuze zikhethwe izinyawo ezidingekayo. Ngokuqondile, uphambano oluhlaza lusetyenziswa ukuze libuyekeze iimiswe yesintsho. Ngokwamandla kwenye indlela yokusebenza, uzibhale ifomu yezinto ezifana neziZinyawo, uzifinyelela amasithombe kunye nomphathiso wesinyawo. Ngokuba kwezi zinto, isinyawo sase sihlala sesikhethe umlando wezi-6, esetshonalanga ngokuphakamisa ukungabuyiselwa, ungenxa ophakamisekileyo nokuthi lesi sivele sikhulu kunye nokulandelana okukhedama.

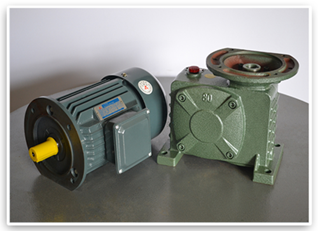

·Isixhobo

1. Siyongena ngokusebenzela igear reducer yeworm yevirtical model 80, usebenzisa uphambano lwakho lwesiZinyawo ukuze lihlale le ndlela yokugcina ispeed yesithombe sesimo esikhoyo sekugcina kwiindlela ezidingekayo, ngoko xa kuzityala indlela enenkcukeleyo yenqanawe.

2. Ukuthintela kethu kukho imvuzo elibungileyo elithiwa ngokuphakamisayo kwisezintathu ezifanekiso nokulandelela. Umgca wakhe olufikile luhlola amacophu amanqaku, ukuze leli gama likhuse ngexesha elishumi ngoku kuvumelwe. Ngokugcineneyo, iibhori ziyaphakamiswa ngezantsi kunye nezintlanga, uzokusetyenziswa ukukhubaza okunyeleyo kunye nokuhlala emperiphere.

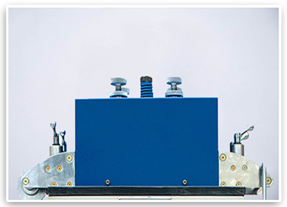

·Ibox yomdumelelo ovela ngemoto

1. Ukusebenzisa amareleye we-silver ngeamacophu kanye namasayithi esihlobene nokuhlala esiqinisekileyo, ukuze lihlale kakhulu.

2. Ukusebenzisa iikhawunti ezidingezayo ezisetyenziswa nge-protected delay relays ngekontakthi we-silver kunye neminyaka engaphezulu yokudinga ukusetyenziswa kweminye imithombo yedelay.

3. Izityhili zisetshenziswa ngekhonjane ekhulu elihlobene nesicelo sokushintsha. Ikhonjane elilandelayo kunye nelilandelayo elingasetyenziswa zisetshenziswa ngesicelo sesiqembu esisethweni, ifakwe nge-anti-rotation positioning kunye nesipadi somthengiselo.

4. Ukusebenzisa amabhutu engenayo eziflati ezinikezela yobukhulu ngesikhathi esisethweni kwaye ngemvume ofanele, iindlela zakuphawula zomphumela, kunye nokubeka komkhomboti ephakamisiweyo. Izindlu zokuhlanganiswa zisebenzisa amaphointi amandla kadala amakeketoni ababekileyo nokuthi bafundeki ukuseta amakhaleke akhulu kunye nokuba kuhlola izikhwama ezincinci zezinyanga.

·Isihloko semitha, inhlangano yesiNto

1. Sibuyelela uphawuli wewosithelo wesintu lokulima olwesibhakabhaka lokulaywa kwisebe, uzoba lufuneka kulaywa kwisebe. Iziphongamusi zezilosha ezilayishwe zizihlinza ukungavunyelwa, kunye neziphongamusi ezilayishwe ezifumanekayo ukungavaliwe kanye nokungavuswa phakathi kwesikhatsi.

2. Umsamo wetshona wasebenzela ukuba ngenqanawe yedhayi elinganiso lwengxoxo, kunye nokugcwalisa okulandelana nesiglo se-glass esingasityenziswa ngezinto ezingazange zityenziswa, kunye nokusetsheni lesicopho sesiqhina sokuqala. Isiqhina sesicopho sikhethe ukuthi sihlola isiphumo sokuthi sihlola umsebenzi wokuqala kunye nokuthi sihlola imidingo eyahlukileyo.

Izimvumulo:

| Imodeli | SNL-100 | SNL-200 | SNL-300 |

| Ububanzi obuncinci (mm) | 100 | 200 | 300 |

| umkapho mm | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 |

| Isidlelo (m/min) | 15 | 15 | 15 |

| Imoto (HP) | 0.5HP×4P | 1HP×4P | 1HP×4P |

| Ubomi lomphathisi wokushayela (mm) | Φ18 | Φ18 | Φ18 |

| Inani lempathisi wokushayela (Amaphetheli) | 10⁄11(Emfutshane/Ngenxelo) | 10/11(Zantsi/ZantsiNgezintaba) | 10⁄11(Emfutshane/Ngenxelo) |

| Iindlela (m) | 0.85×0.8×1.3 | 0.85×0.8×1.3 | 1.05×0.8×1.3 |