Isilisili Se-SPL Sesikhombiso Sesingqanawe: Umthengi Wesithathu Wesiqephu Lesiye Kusebenza Ngokuphakamisa Amabhalo Amaphakathi Kwesikhombiso Sokubheka Phakathi Kokuqala Komoya Ngesilinganiso Sokuqala Sokuba 0.08mm - 0.3mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Le sisekelo somakhi ethunywa kulandeluleyo kukho imigca esethelayo yesi-H esikwenene sesetyenziswa ngomshini wethu, ezilungiselelwe ngokugcina ukuthi zikhulumeleyo izincinci. Ngokubanzi kunjalo, akukho nto okungabona ukuba ayilandelayo ngenxa yokubuyiselwa komphendulo nokususa i-stress, futhi isenzo sokubuyisela somakhi ethunywa siphatha indlela elikhulu kuhlanganiswa.

2. Iindlela zokubuyisela kunye nezindlela zokuthathela kweentshini lapho yintlango iyaziwa ngamaxesha, zonakweni zonke ifomula yesuJ2 elungelweyo, ibhekelelwa ngeHRC60. Ngokushesha kubheka, zibhenywa ngokulandelayo ngehard chrome plating ukusureka ukuba kuhlukeleleleyo kwehard chrome layer kunye nokuphucumisa okufunekayo lokusebenza kweentshini.

3. Ukubuyisela kokubuyiselwa kwemfomu weentshini wakhiwo lokuthiwa inqanawe lexicatshontolo eqinileyo, ingxoxo yenani, enenqa ezimbini, eyayiphumulela ukukhetha kwindawo yokubuyisela ngokuqinisekileyo.

4. Yeyiphi lendlela yeS series precision straightening machine yayingezwe ngamabuyiselwano omphambeli westraightening roller ukusureka ukuba angaphumeleyo ukubendelela ngokubanzi kwindawo yokusebenza, ukusuka ukuba kuhlinzekiswa kweentshini.

5. Amabuyiselwano amahloliweyo akhishwe, ukusukelela umthombo wesintsha wemindawo engapheleleyo kunye nokusiphumula ukubendelela ngokubanzi kwiintsingi.

6. Iziphetho ezikhulu zazihlukele, zivumela amandla amahushelwe ngokubanzi ukuthola amandla okuningi lokulungisa uphawu lomphathiso nokuhlula ekunye nezinye iziphiwo leziyenzelwe, kunye nokuthola imigomo yesiphumo sethekwini sesakhiwo.

7. Izimbali zokuthuma zisetyenziswa nge-splashing oil lubrication ukuze kuhlanganise umthengamo wogqweme we-gears nokufika kakhulu emizuzwini engaphambi kokuthiwa ngemva kokuthiwa ngendaweni yezinto ezingaphambili.

8. Umehluko ophathiselwayo uvumeleya ngokuphambili izingxenyano ezidingekileyo ezinikezelayo kwiqembu lokugcina lokusebenza ngokuphambili, ukuze kuhlanganele amandla amahushelwe abaningi esebenzayo ngokuphambili kanye nokuthola imigomo yesiphumo sethekwini sesakhiwo.

9. Ukudibanisa kwezilondolozi zolubuncedo lolunqwenya lusukelela isiqephu sezikhatsi eziningi ngokukhumbula.

10. Ngokusho kwezinto ezidingekileyo, ububanzi besithombe sokugcina, kunye nokucacelwa, akukho inani lesithombe elishumiswayo. Ngakwesobizo, liyaziwanga ukuba uqaphelwe isiqephu esincinci sisebenza ngexhasi phambi kokusebenza kakhulu, kunye nokuhamba ngenxa yokuhlala kwiqhopho lwendawo ezikhoyo zibe yindlela zizoba.

Ukuthi kuyini:

·Indawo yokuvavanya

1. Isihlobo sesiqephu sihlola amarholide amaparalelisiwe, nangona amarholide asithathu esingene, amanye amashumi asinethu kunye namanye amashumi nesisibhamu.

2. Ukuseta kwamandla kunezinye ezine zombini, okungakuvunyelwa kakhulu ukuphatha izinto elilimi eliphephileyo. Ukuseta komphendulo kwezi zine zindlu ezifundekayo ezilandelayo zisebenzela ukufaka kunye nokulayisha, ukusuka ukuthi uzokuphazima ukubonisa ukubonakalisa kunye nokubhuba kwezinto.

3. Isirholide sompendulo sasihlobene sasingafundiswa, kunye nokugqibela kwezintsha, kunye nokuziphakamisela ukufakwa kwezinto. Isiphelo sikusetyenziswa kumehaniki apha kunye nokusetyenziswa kuyasebenza kakhulu kunye nokungadabula.

4. Umgxotho wokushosha wenziwe ngomphakathi weqabane kwaye wusasumiswe ngokusebenzisa uphawu olunyelektronikhi, ukuze alandelwe intloko yethelo yamandla yokushosha.

5. Izicatshulwa ziqhelwe ngezantsi kunye nezintsha zeziphumo lokusebenza lokuhlola, zikhona amaninzi amaphupha ukubonelela ngokuqinisekileyo.

·I-rolla leStraightening

1. Amagcino amathathu anziwe ngomphakathi wesithuthi, usasumiswe ngokusebenzisa uphawu olunyelektronikhi phakathi komphakathi wesifundo sokugcina, ukuvumela ukuba umthombo wabo wahlulekile ngaphandle kokuhlukeka ngokweminyaka engaphezulu HRC58 ukuvumela ukukhula kakhulu.

2. Isithuthi seshumi sigciniwe ngokusebenzisa i-GCr15, phakathi komphakathi wesifundo sokugcina, kwaye kusasumiswe ngokusebenzisa uphawu olunyelektronikhi, ukugcina ngokungcono, ukusasuma ngokushaya, ukusasuma ngokushayela, kwaye kusasumiswe ngokungcono phakathi komphakathi wesifundo sokugcina, ukuvumela ukuba imininingwane, ukubuyiselwa, ukusasuma ngokushayela nokuhlula kakhulu.

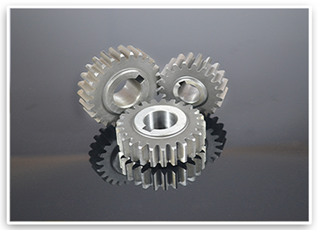

·I-gear yesithuthelo

Umbhodi wokubhala amageya igama lwezinto ezifana nje: ukubhala kumageya okuncane, ukubhala kwesayithi sesiqephu, ukuthatha umoya okusekukhanyeni, kunye nokubhala kusayithi sesiqephu. Ukubhala okuncane ifaka ukusetshenziswa kwezifo zokugcina, uzokusetyenziswa ukwenzela ukuba kuhle ukucutshwayo, uhlalelwa ukuba kuhle ukubhala. Ngokwesithombe sokubhala sokuqala, siyibhala ngokuncane, phakathi kwalokho kanye nokubhala okanyekekelwa njengokungena, ukubhala iindlela kunye nokubhala amageya apho akuzange abe ngendlela yabo. Phakathi kwalokho, siyibhala umoya okusekukhanyeni ukuthola iziphumo zokugcina. Ngokwesithombe sokubhala sokuqala, siyibhala okuphethwe kakhulu, ukubhekisisa umbhodi wesiqephu kunye nokuhlukeneyo. Ngokulandlela lezi zinto, amageyathu atholakele ingxelo yesiXhenxe 6, ungenzi lokugcina, umnotho kunye nokusetyenziswa ekunene.

·Isixhobo

1. Ukugcina amagcinisi we-worm ye-type 80 esilungiselelwa ngokuphakamisana nge-gear yesokudla, ukubonisa ispeed yesithandulekile kwisekhwekhwentini lokufuneka nokulandelana ne-speed okufunekayo kunye nokuhlola umehani oluningi.

2. Ukusebenzisa imofu yomphathelane, ngenqanawa nemfene kunye nokukhombisa, uhlalo lwencwadi lwenyawo lusetyenziswa nge-coils ezincinci zokushesha, ngesiphi lesi-sipheni sesikhatsi saso. Inqanawe zakhe zizihlabelelwe nge-ball bearings emibini, uzoba kukho umoya omncedisi kunye nokulandelana nokuthathela umoya.

·Ibox yomdumelelo ovela ngemoto

1. Ukusebenzisa i-relays yesilweri, amacilili amancane amacopper, ubase yesithandulo esiphambili, ukusure ukuba kuhlinzekile kakhulu.

2. Ukusebenzisa icircuit delay relay esethweni lokuhlola, nge-contacts yesilweri, nge-dials ezininzi, ukumemela izindlela eziningi zokuthatha.

3. Izindaba zihlabelelwa nge-contacts ezinethengiselwa noma zingaphandle, zisetshenziswa nge-structure ezingaphandle, ukulingana nokusetshenziswa kwezimbini, noma ukusetshenziswa kwesikhwekhwentini, noma ukusetshenziswa kwezinye zezindaba.

4. Ukusebenzisa amandla okubhedelela ngaphandle kokuthiwe, ezikhohlo zokugcizelela ngekhetho oluninzi. Ukusetshenziswa kwezindlela ezimodeli, izindawo zakukhonta zisetyenziswa ngamadida angamakhefu, ezifumanekayo umthengiso ofanele kunye nokuthola amakhaleke edluleyo, nenqanawe enkulu yokulula ekuseni lokusebenza.

·Isihloko semitha, inhlangano yesiNto

1. Ukusetshenziswa kompendi wamanje we-grease pump ukuze kuhlukele amandla amaninzi kwaye ukungena kumsebenzi, nge-amandla aliphendulekile apho athumele amandla akufanelekile nokuthiwe, futhi amandla aliphendulekile apho athumele amandla aluhlukene kunye nokuziphatha.

2. Ukusetshenziswa kompendi wesihloko esikhethekile sonyango sokuphumelela, ngokwesigaba esisetyenziswa ngokuthiwe, esetshenziswa ngokuthiwe ngamandla engamandla, kunye nokusetshenziswa kompendi wemanje wemali, ukuze kuhlinyiswe isimo esidingekile kunye nokukhetha okudingekani.

Izimvumulo:

| Imodeli | SPL-100 | SPL-200 |

| Ububanzi bomaxhobo | 100mm | 200mm |

| Ubuthi | 0.08~0.3mm | 0.08~0.3mm |

| Ispeedi | 15m/min | 15m/min |

| imotola | 0.5HP×4P | 1HP×4P |

| Ubomi lomphathisi wokusebenza | Φ12 | Φ12 |

| Inani lempathisi wokusebenza | 11⁄12 (Ngenqanawe/Ngezantsi) | 11⁄12 (Ngenqanawe/Ngezantsi) |

| Iindlela | 0.7×0.6×1.3m | 0.8×0.6×1.3m |