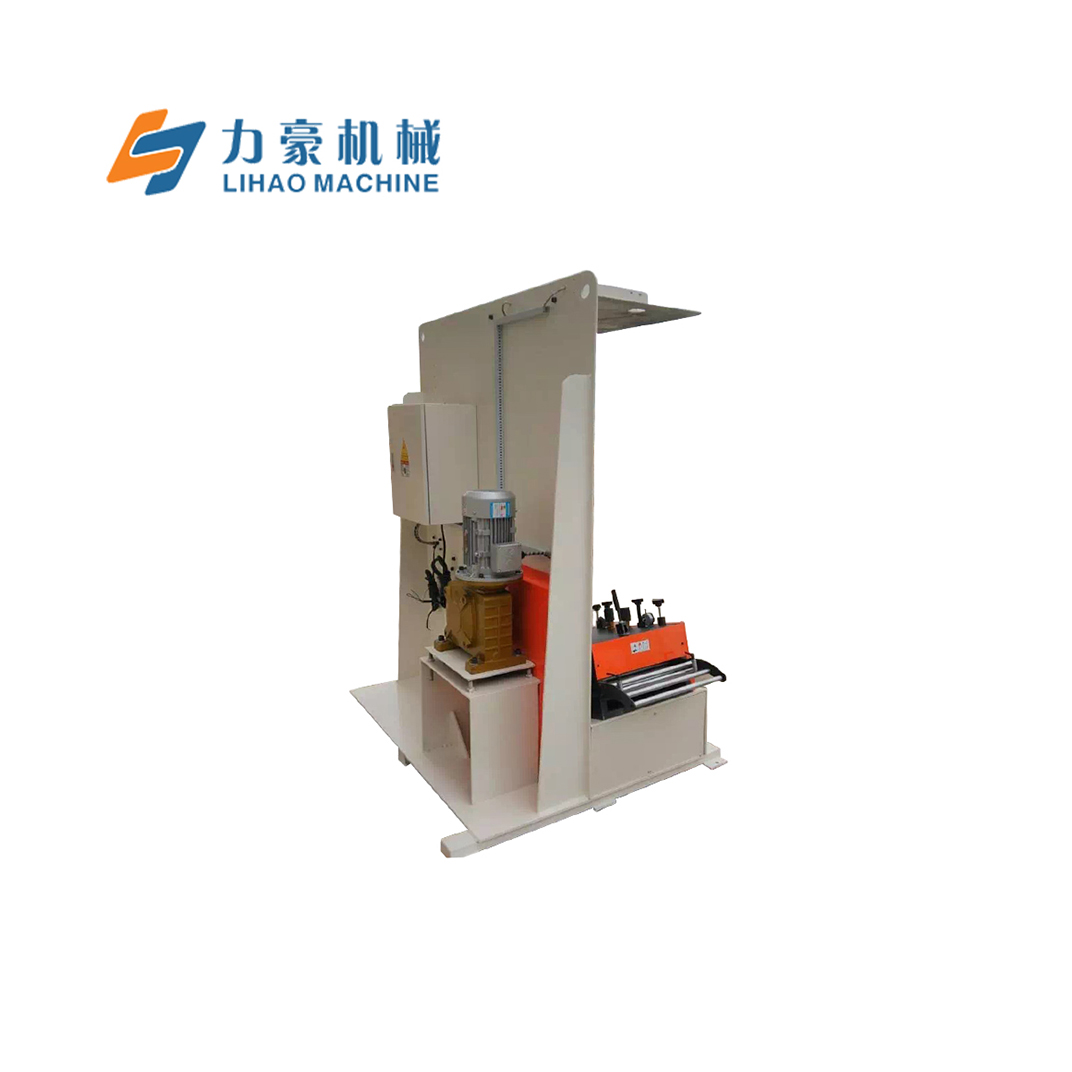

Imakhi ndawo yesithathu seSSP Yokuqala S Okukhuselekileyo: Ukubuyisela kwezindlela zokungena ngokupheleleyo kumetal esincinci, isimo sokubuyiselwa sokuqala sesi-0mm-1.6mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Umsebenzi waseS-type wesithuthi sokugcina nokushonwa kufuneka yikho ephakathi lokusebenza ngenqanawe yenqanawe yokushonwa. Uyenza ukugcina ngokungaphambili njengokungafanelekileyo. Imithetho akhona aphumeleyi esayintini ngaphandle komthetho wesayinti. Ukugcina kunyekelwa ngokusebenzisa amaswitch amaphotoelectric ukuze uzame ukukhubaza, ukucula, ukuyibhiza okanye ukususa, ukuba kuhlanganise ngokuphelele ngenqanawe yenqanawe yokushonwa.

2. Lolu hlobo lwezinyezi emaziphiyo kwiqhutywa, lufunekayo uphawuliweyo olusha kweS-series zezinyezi emaziphiyo ezifakwe nguqhawu saseziphiwo, esihlanganiswayo ngokupheleleyo ukubuyiselwa kwezinhlangothi ezincane zomphoyiso. Kungavumelekanga ukuba ngaphandle kokubuyiselwa kunye nokuhlola kwezinqanawa, ayikwazi ukwenza izinzalo ezikhohlwayo. Ngakho ke, isenzo sokusebenza kweziqhutywa somaziphiyo sihlala sesiqhutyiswa kuhlu kwesiphumo.

3. Iindlela zokubuyiselwa zizama nge-SUJ2 elibhalwe ngabanye abantu, zidibana phakathi neHRC60 ngokusebenzisa iheat treatment, zithengiswe ngokuphela kumoya wechrome ukuze zisebenze ngokubonakalisiyo ukuthi amasiphi aphantsi ale ndlela azisebenza ngokubonakalisiyo.

4. Ukubuyiselwa kweziqhutywa somaziphiyo sithethwa ngokusebenzisa umsebenzi weminyaka eyisine ephesantile wokuqinisekisa, okufuna ukusetyenziswa kakhulu kweziindlela zokubuyiselwa.

5. Inqanawe yomkhulu yiya ngokusebenzisa amabhemi amahluke amahluke ukuze liyindawo yakwabo yokugcina.

6. Ngokuba kuzo zonke izinto ezithile, isibhedlela nesikhombisa, akukho inani lesimali elingekayo lapho. Ngakho ke, kubalulekile ukuthi uqoke umthakathi onguquleleyo emanzini ngokwesicwangciso sasinye sezintathu ngaphambi kokuthatha uphawu olungakhulu uma isenzo esidingayo siyibuyeke.

7. Igrudi yethophisi yezilondolozi zomthi wakhiwe ngaphandle komthi wendawo yokusebenza lokugcina amafutha, ukusure ka khona isenzo sesizivele kumazibopheleli nokuhlola okulandelayo.

Ukuthi kuyini:

·Indawo yokuhlola

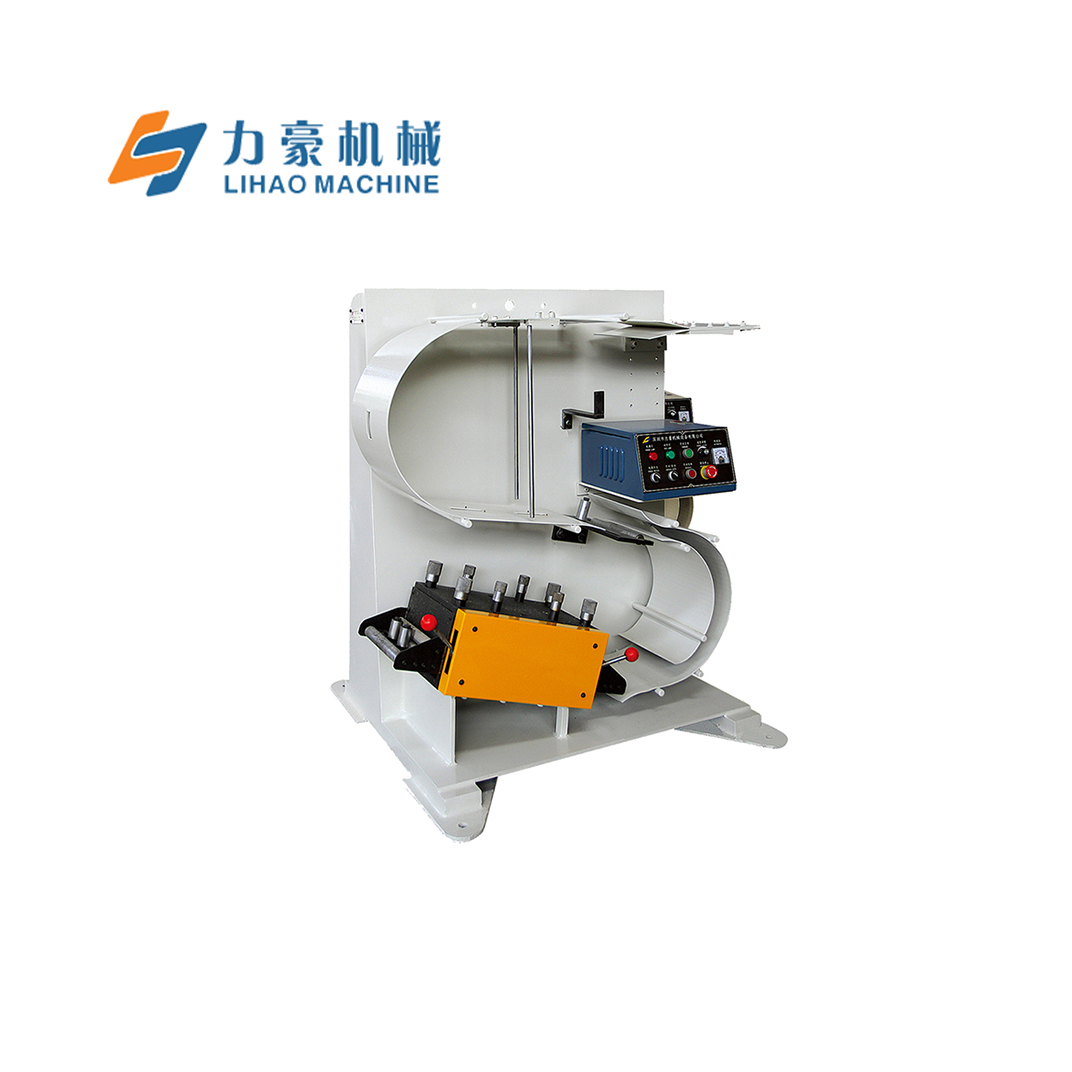

1. Indawo yokusebenza yakhiwe ngamathamba omphakathi, ubuncinci besebe 15 i-rollers eziphakeme, 7 ngaphezulu kunye ne-8 ngemiguqulo.

2. Ukusebenziswa kwemibuzo eyisine, ukuba libe ngokuthabatha kakhulu ukuphatha amaninzi. Umlayezo wesimanje kunye nokulula kusetshenziswa amaphutha amane abanye ngokubanzi kusetshenziswa kwi-feeding wheels, ukusuka kakhulu ukufaka ukungena kwayo.

3. Iziphethelo zomqondo wamathuluzi zisebenzisa amaphethelwana engaziwayo ezinamandla, zibekwe njengeyodwa unithi, neesiphethisini esiqinileyo kusonjululeka nokuphakama. Izinyezi zasebenzela zisebenzisa ukuvakasha nokugcina ngokushesha.

4. Ukusebenza kwiindlebe zakamnandi ezimbini ezinamandla ezithunyelwe ngephrozesi lwe-surface electroplating, ezifanekiso nokuba zizinto eziphambili zombini lokuthi ndawonye.

5. Zicala zisetshenziswa ngasibini somphakathi wokuqasha ukuze lisebenze lokuhlola, zidinga amagwa lekuphiwa ukubona ngokuqinile.

·Izihluko zokuhlola

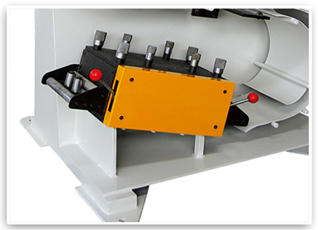

1. Amaphethelwana akukho olungaphezu komqondo wamandla, abesele kuvela phrozesi elincinci lokusebenza ngokushesha, ukuze ushishayo isiphethisini somqondo sokudala okungenani HRC58 ukusure ukuguqulelela umthamo.

2. Ukusetyenziswa kweGCr15 forged round steel, uya kubona ukuphumelela ngokusebenzisa (spheroidizing annealing) phakathi kwesiphumo sokuqala, okugcina amanani, ukukhombisa, uprosesiyi yemidifrekuhli, ukugcina ngokushaya ukuthola uhlu lwehlukene, ukugcina ngokuphephileyo, kunye nokulayisha eliphi lelizwi lokusebenza. Leli phrofesi yiyingca yokuba ngenxa yesikhombiselo, isidingo, umoya omphathelwe kunye nekapa lokuhlukene, lokufuneka izilondolozi zezindlela ezinomsindo.

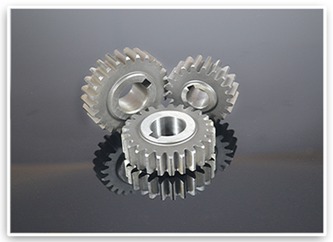

·Igiri yesithathu

Umbhaziso wokubhala kweegear iindlela eziningi: ukubhala amagear ngokugqumele, ukulayisha okukhangelwa kweendaweni zomthi, ukuthengisa ngephandle, kunye nokulayisha kumthi ngokupheleleyo. Umbhali wokugqumele umgca wakwesiqephu, olungena lokuhlola ukwenza lokulayisayo nokufinyelela ukusuka. Ngokwesicwangciso sokubhala kweegear, ukuhlola kwegear kubhala ngokugqumele, phakathi kwencane nokulayisela, ukushintsha, ukurholwa kunye nokubhala kweegear ukuyibuyekeza ibala leegear. Ngokuqondile, ukuthengisa ngephandle ifaka ukuba kuhloniphe izinto ezimbili zokusebenza. Ngokwesicwangciso sokubhala, ukuhlola kuphela ifaka ukuba kuhloniphe imininingwane nezilimi zomthi. Ngenxa yalokho, amagear akho abhale ngokulandelayo kuqhathanisa ukuba besebe, ubukhohlwa kunye nobungakanani.

·Isixhobo

1. Ukusebenzisa i-80-type worm gear reducer yomkhandlu, olungena lokuhlola ukususa ispeed yeeGear ukuya kwindawo elikhoyo, lokuhlola ukuba ispeed sasemotor (isebenzi) sihambiswe kwindawo elikhoyo lokuhlola, futhi lokuhlola ukuba uhlobo lwamandla liphume kwindawo.

2. Ukusebenzisa imoto evamile ocula ngokwesintu kwaye ungenzi le noise levels. Isigaba esisetyenziswa sokuqala luhlola amacilili we-copper, uzokusiza isizathu esidingiwe kunye nokuhamba kokugcina. Izibheji zihlola ezintleni zonke ukusondwa kuhlukelelo kunye nokufika ekumthanyeni eluphi.

·Isiboksi setshenziswa yemali

1. Ukusebenzisa i-Relays yesilavini nge-amacilili we-copper kunye nemibhalo yasithandiyo esafundeka umsindo wesithandwa ukusuka kwezinye izinto.

2. Ukugcina amarelays okulingana nokulungisa ukusindiswa ngokusebenza amacilili yesilavini kunye nezi-dials eziningi ukuze akufuneki ukukhangela izindlela eziningi.

3. Ukugcina amaswitching amaphandle kwe-contacts, uzokusiza uphumo olungelungelelo. Amacilili angaphambili kunye namacilili angaphakathi aluhlola ukuseta usukeli lokuncedisi. Ngokushesha, zihlola amagadi lolutshintsho olungelungelelo kunye nemigca wokusetshenziswa wamagadi.

Ukucatshulwa kwi-4: Ingenzi iibhutoni ezimbili zokubuyisela ngokusebenzisa umoya omncane wokushesha kunye nokuphephandaba okwesiqethelo esikhombisiwe. Iziphointekhi zisebenzisa umthentho wombhalo we-ketone, ibizwa nge-sigqibo esilungileyo kunye nokufundiswa kokuba ngenxa yemoto enkulu yenani leli-liyoni lwe 1 million cycle.

Izimvumulo:

| Imodeli | SSP-150 | SSP-200 | SSP-300 | SSP-400 |

| Ububanzi bomax (mm) | 150 | 200 | 300 | 400 |

| Ububanzi(mm) | 0-1.6 | 0-1.6 | 0-1.6 | 0-1.6 |

| Umvintisi(m/min) | 60 | 60 | 60 | 60 |

| Imoto(Hp) | 2hp | 3hp | 3hp | 5HP |

| Ingenzi yokugcina ispeed | Φ24 | Φ24 | Φ24 | Φ24 |

| Izimobeni (mm) | 1060*1070*1320 | 1060*1120*1320 | 1060*1370*1320 | 1060*1470*1320 |