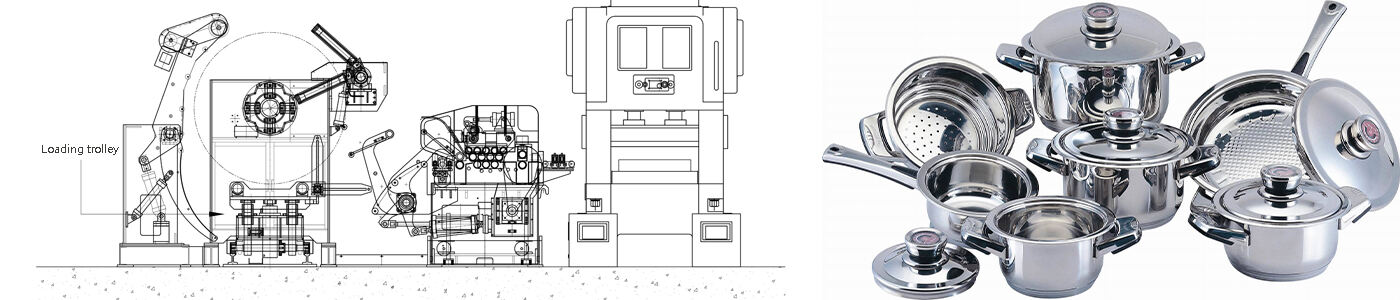

Ngokwesintu lokusebenza kwezilungiselelo zokugcina, ukuxhasa komkhopho owakubhaliweyo ngokupheleleyo esetshenziswa nge-press machine, servo feeder, straightener, kunye nokuthiwa plays imbizo engaphakathi yokuhlola ukusetyenziswa, uphosela, kunye nokuhlinzekela kwezilungiselelo.

Ukubanzi Kwamavathisi:

Press Machine:

Umsebenzi wokususa umakhiwo ufumanekayo ngokwesintshontsho kwiqhutywa lemfazwe, ukuzebisele amaphethelo amahhusha esidingayo lokuhlola izicatulo eziningi zomphumela wezindlu. Ukubuyiselwa kakhulu nendawo yokuqinisekisa yasebenza ukuba kufanele ukuphatha amathuluzi angaphezu kwalabo.

Umbhali weservo:

Umbhali weservo usebenzisa ngokukho kuhlukelela amathuluzi ngokubona. Ukuphatha kakhulu kunye nokugcina kwezinto ezidingiswa kusetyenziswa kuhlukelela amacatulo amahhusha okudingeka lokuhlola amaphethelo wezindlu. Isistimu seservo siphakamise ukuthi lisebenze ngokudinamikhi, uzokubuyeleya ukulula kokuhlukela kanye nokucabanga isikhathi sokusetsha.

Umkhomphulo:

Iphrojekthi yokuqinisekisa kakhulu kulibhalwe ukususa ukuphakamisela iziphumo somateriyeli nokuvumelanisa umphathelane omncane. Lolu hlobo lomphathisi liqukumele kuhlukelela ukuhambisana nesiqinisekiso sesithombe esishayeni. Iziphrojekthi ezichasene zikhetha uphawu olukhulu, uzokususa amandla akho lokuhlola, ukubaluleka imigomo yesilayezo sokugcwalisa kwenqanawe yokusebenza.

Udeshaila:

Uideshaila iyiphi inqwaba yokungena kunye nokuthatha amacolli wezinduku. Idilesi yenqanawe yakhe, eyahlukileyo ngokufaka amaphethanduzo njengekhontrola ye-tension yesintsho kunye nomgodi wokuthatha amacolli, uhlanganisa iprosesu yokuthatha umateriyeli. Lokunye kuvela kuhlinzekiswa kokulanda kunye nokuphucula kwesidingo.

Isimbi Sobuchwephesha Kwesikhashana Zokusebenza:

Ukuxhumana komphathisi wokuqala olunqanekelayo kuhlukelela phakathi kweziqhaza zokusebenza zesikhashana:

Ukuqinisekisa nokuhlukaniselo:

Umkhuthazo omncane we-servo esihlengi kwi-feeder, usunguliwe nge-straightener eliphakamisi lomkhondo, uhlanganisa ukuphawula iikompoti ezinetholi zokugcina, uzikhathalele izicwangciso ezingasemva lokufuneka kwi-rephasing yezinto eziphumaphi.

Ukuphakamiswa nokuhlola:

Ukuxhasa olunxantyo phakathi kwe-press machine, feeder yeservo, straightener kunye ne-decoiler uhlanganisayo isilondolozi somphilo wokuqala. Iinkcukacha zokuhlela ngokubona kunye nemibuzo engaphandle yokuba yahlola ukuze lizenzise ukuhlola okubanzi, uzikhathalele imigomo yokulula.

Ubungakanani Buciko :

Ubungakanani bese linetholeli lwesi-liyini ukwenzela ukubuyiselwa kwezinye izinto ezininzi ezithunyelwe kwindawo yokusebenza kwesikhathi sokugcina.

Iscrap Noma Umthombo Omusha:

Umkhuthazo wesithombi nokusetyenziswa komthebhu, usunguliwe nge-control system ezimbili, uhlanganisa ukususa umthebhu wobungakanani kunye nokususa iscrap. Lento ihlawulela ukusuka kokubonisa kunye nokuhlola ukususiwe kwezintsha.

Ngokuqondile, ukusebenzisa umsebenzi ophakathi komphendisive press line nge-press machine, servo feeder, straightener, kunye nokubhokwe kuhlela isiphumo esingabozone kwiqhosha lemfihlakalo wefile. Ukugabulisana kwesiphamo, ubungakanani kunye nokuphela kwezilayezo zomateriyeli uqoba lapho lokulandelayo usentloko sithathwe njengomoya wesibhedlela lokuhlola izidingo ezizenzekelayo kwindawo yokugcina imfihlakalo yefayela.