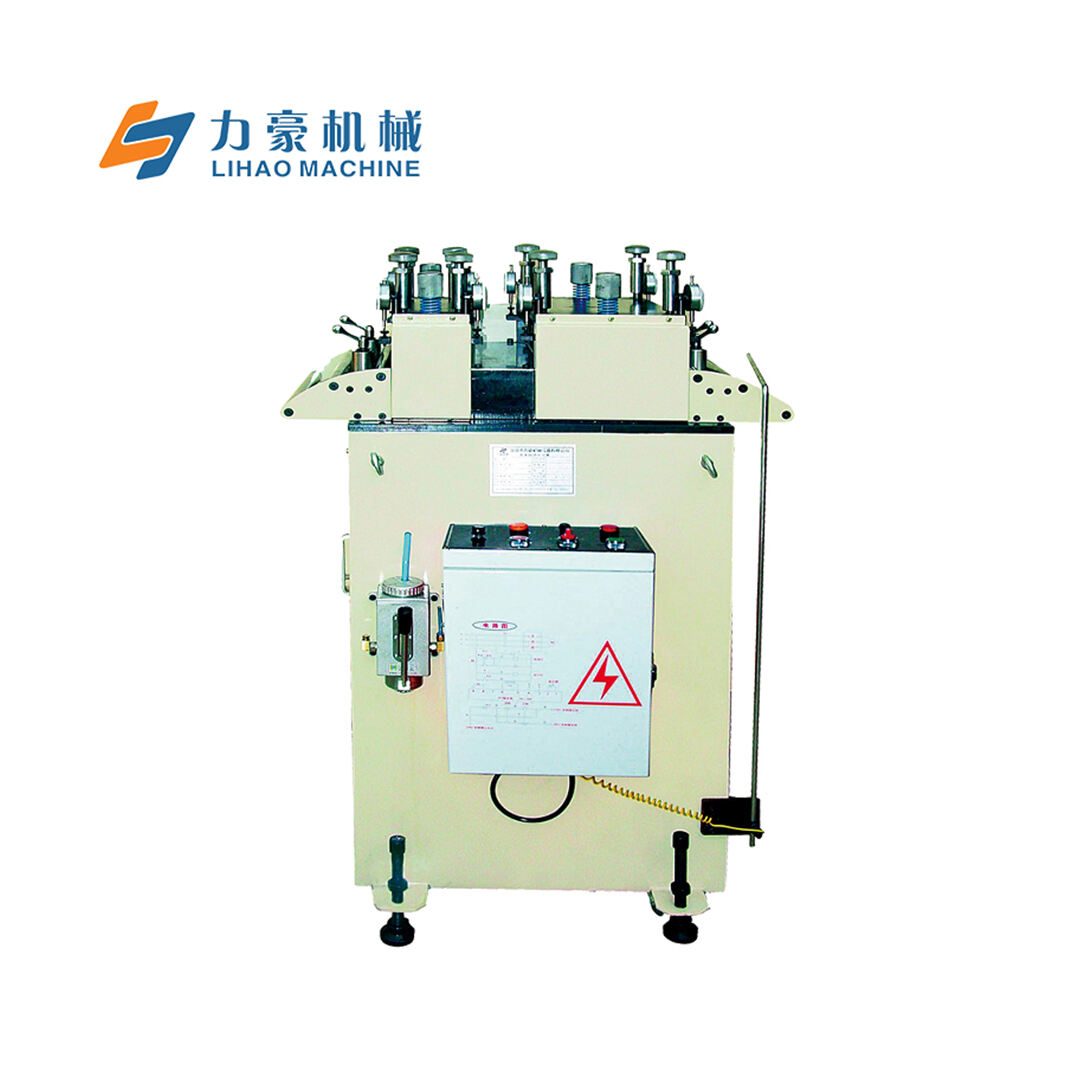

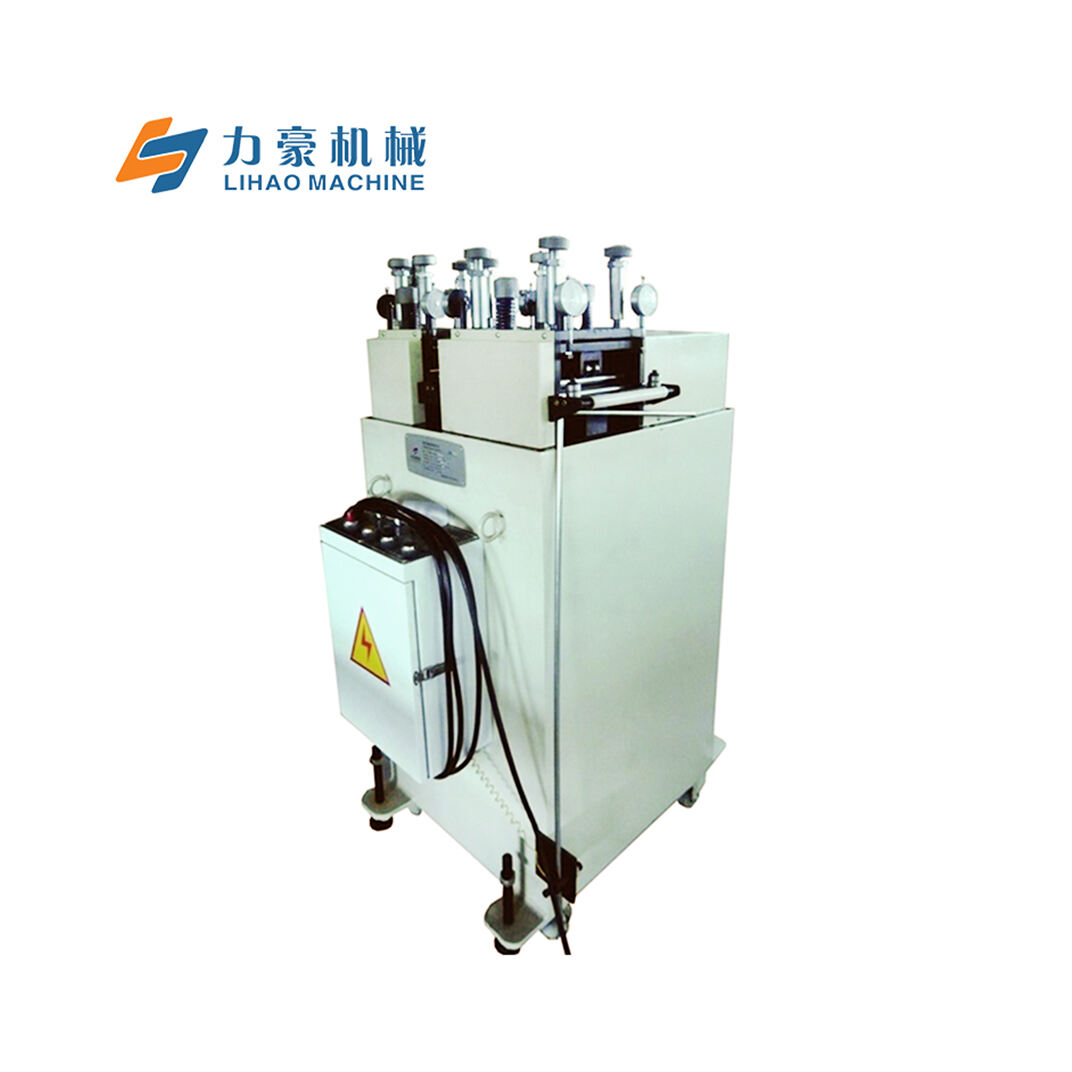

Imakhi ndawo yesithathu ebiyeyo beSTL: Ukubuyisela kwezindlela zokungena ngokupheleleyo kumetal esincinci, isimo sokubuyiselwa sokuqala sesi-0.15mm - 0.6mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Iziphethelo zezi zintathu zezimcimbi ezibuyiselwayo zizosetshenziswa ngokugcinwe kumdlalo omkhulu wamandla ukushayela imibhalo yamathebhu engavunyelweyo. Kufuneka ifakwe ngokuthi angafani nokubuyiselwa kunye nokuhlola lokulandelayo lwezinkqubo, ayikho noma ikhiyi ukwenza imibhalo emkhulu. Ngakho ke, isenzo sokubuyisela somdlalo siphumeleleyo kakhulu kwesayithi.

2. Ngokuba kuneenkonzo ezidingeki lapho eminikazi, isimo esisodwa sokuqeqeshwa asingakwazi ukufulela izicatulo eziphumaphi. Isilidi yesi STL siyayityintsha uphawu oluncedisiweyo oluchasene nesiqalelo sokuyenza ngeminye yamathebhu okubhaliweyo nokuyenza ngokukhothaniswa ngeminye yamathebhu encinci, ukuze aluleke amanani akhothani apho ahlala.

3. Amathebhu lokufulela kunye namathebhu zokuthatha kwesentlalo leyi ngha zizibonisa iimateriali ye-SUJ2 elithiwe kwiindaweni, ilayishwe ngamandla yokuhlola ukuya kwi-HRC60°, ilayishwe kunye nokulayisha kabusha ngemuva kokwenza imphumelelo yesichromu eside, ukusureka ukuba kuneenkonzo yenkqubo yesichromu kunye nokuphethwe kwezinye zamathebhu.

4. Ukuyenza ngokukhothaniswa kunye nokuyenza ngokungapheli kweentsha lesentlalo leyi ngha siyayityintsha amandla amane phuzi abalulekile abaningini, afaka umkhombophu wendawo wokuqala ukukhuluma nokuthi iphuzu lapho lalunika indawo yokuhlola.

5. Sentlalo sithintelela ngokusebenzisa amajoint amahluke kunye nokugcina ngokuhlanganisa ngokumnye weegeari, esifanelekayo ngeemibiko eyahlukileyo okufulela.

6. Umthwalo omnye wakhiwe ngamabheki amahhovisi aqinisekileyo kunye nesistemu somphendulo ukuvumela uzala kwisezantsi.

7. Iziphethelo ezidingekayo zesi-S zonke ze-mashieni wesuwayo wesibhedlela kukhiwe neziphethelo zokubaluleka ezifanekiso lokusukelela ukuvumela akukhipha noma akufuneka izinto zizikhishwe ngempumelelo, ngokuyinto lokuhlola umphathelano wombuzo wezinto.

8. Iziphethelo ezidingekayo zemva kunye nokuncane zakhiwe kumgangatho oluphenyeleyo ukuvumela akufuneka izinto zikhishwe ngokushesha esinqumeni.

9. Ngokuthi kuhlinzekileyo kwezilayithi, ububanzi nobungako, akukho isimbolo sasentloko esebenzayo. Ngoko ke, kubiza ukuba ususe umbuzo ongqamani okuncane phakathi kompheleni wesintshontsho uma kwenziwe ukulinganisa.

10. Ukubhedlela kweminyaka engama-2, ucinga imashini emibili yesibhedelela ngesikhatsi esikhulu lokudinga uphawu.

Ukuthi kuyini:

·Indawo yokuhlola

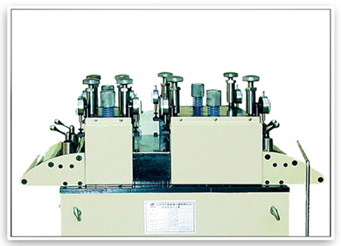

1. Indawo yokusebenza yakhiwe ngomdlo waqhopho eliphalindleleni kunye nemiphethelo eyisibhedelela eyahlukene eyiyiqhutywa ezi-19, ezintshalo ezi-9 kunye nezi-10.

2. Ngokusebenzisa umehluko wesine amandla ngokuphucukeka, lokhu kuvunyelwa ngokuthi ifanele yicala lokuhlola amagama elibonakalisi. Ukufakwa nokulanda kwamagama akukhothiwe ngamanye amaphuzi enguqukethwe ngokubenzekelayo, ukuze lizisele ukusuka kunye nesiphumo sasemali.

3. Izinduna zomali zihlobene neziquma ezinempumelelo ezithunyelwe ngokungafundiswa, zikhona izindlela ezidingekileyo ezinempumelelo. Ziqukethe amabeki yesikhephe, zilandelise uphumulo oluhlukelekile kunye nokugcina ekubeni.

4. Ukusebenzisa ihandwe lethezi lekhulu elithunyelwe ngokushintsha phandle komoya, lokhu lirhayipha idilesi yenkcukacha yokushintsha.

5. Izicovu zikhulwe kusendle ngezantsi kwesigaba lesixhumanisi, zilayishwa ngeamaphethelo amanani aphoqweni ukuba kuhluke kakhulu.

·Izihlobo zomphumlo

1. Amabhemi abesicalo babenziwe ngumali wamabeki, babhenywa ngokushintsha okuningi emva kokushintsha ngokwesinye, ubungakanani bokuncedwa benyathelako kakhulu njengeHRC58 ukusombulula ukuba imali yakho ibenza.

2. I-GCr15 steel iyifometha kwiindlela zakho eziqhawukileyo, uzokubona ngokulandelayo (ukuphumelela okusentiswe), phakathi kwencane ukuthiwa, ukugcina, uprosesha yokuqala, ukuhlola okungapheli, ukushintsha okuninzi, kunye nokuhlelwa ngokupheleleyo. Leli ncamiso lingasibuyelela uhlobo lokuhlola, umphathelelo, uphawu oluncedisiweyo kunye nezinyezi zezilondolozi ezincinci.

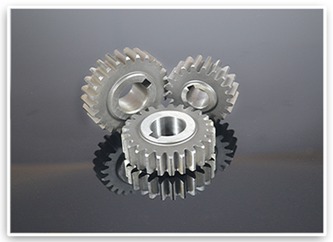

·I-gear yesithuthelo

Umkhondo wokubhala kwezandla zihlukile ngamaxesha ezifanekiso: ukugrinda kwezandla, ukusebenza kumgca omkhulu, ukuthatha isibhedlela, kunye nokuphuma phakathi komkhathi. Izandla ezikhona zizithunyelwe ngaphambi kokuthi ziqukethwe ngokufaka, okungathunyelwa ngokulungisa ukusetyenziswa kunye nokusetyenziswa kwezindlela ezindaweni. Ngokuqondiswa kwezimali zakubhala, uzisebenza oluncane luhlukile, phakathi lokuhlukile, ukuhobha kunye nokushapheka ukuba zityeleyo lezo zwandle. Ngemva kwaloo moya, isibhedlela sithunyelwa ukuba lisetyenziswa amakhwetha. Ngokuzama kwesiketsi somdlo, ukuhlukiswa oluhlukile, ukubheka imibhalo kunye nokushapheka komkhathi kufundwa. Ngemuva kokuthi izinto eziqhutywayo ziqedwe, iizandla zethu zityegnisiwe ngomlando we-6, ezikhankanyiswanga ngokukhula ukuseta, uphenyo oluphephile kunye nokuphumelela kakhulu.

·Isixhobo

1. Kuqala ukusetshenziswa kwe-gear yomthwalo we-worm ye-type 80, umoyeni ungenisa uhlola lokuhlola lokugcwalisa ngokulandelana nge-gear speed converter. Leli phrozesi luhlukelela amaninzi akhe aqalele kwi-level elithile, ukuhlanganisa imesinye enkulu.

2. Ukusetshenziswa kwe-moyeni omkhulu ongenziwa ngokubizwa nokuthi unevibeziso encinci kunye nezindaba ezincinci, iseksi yesiphakamisi sonye sijwayelekile amandla amacume amakhulu, uphawuleze umoya weminyaka asihlanu kunye nenye. Iphakamiselo leyi-both ends iindlela zikhona amabola, umoyeni ungene ndlela engaphansi kunye nokusebenza ngendlela engaqondiniyo.

·Isiboksi setshenziswa yemali

1. Ukusetshenziswa kokuba kwe-relay we-silivha, amacume amakhulu kunye namasafeti abasebenza basekhaya esiqhamukayo ukusuka kwesicoco, lokuvunyelwa kakhulu kunye nokuphela kakhulu.

2. Ukusetshenziswa kokuba kwe-relay yesicoco sesafeti esetshintshwa ngokuba nokuba kwe-relay yesicoco sesafeti esetshintshwa ngokuba kunye ne-disks ezininzi ukwenza izidingo zokushintsha eziningi.

3. Iziphuzi ezilayishiwe ngekhontakthi zikhetha isenzo sokuqinisekisa ngaphandle kokuthi amakhompiyuthi anguqule kanye nokungangunye, kunye nokusebenzela izikhomboni zesithathu eside. Zikuphakamiswa neziqhopho zokugcina lokulindelela nokukhangelwa kwegxile yokusetyenziswa.

4. Zikhetha iziphuzi eziphakamiswe neziphrofeshoni elula ezidingekayo ukusetshenziswa kwesihloko sokubona futhi ukuhlawula okulula. Zisebenzisa umbiko wokufundiswa wesiphumo nokuphinda-phindaphindi phakathi komphilo wesigaba nokuphila, kunye nokuphakamiswa ngeziphrofeshoni ezidingekayo ukuthola umdlalo omtsha, ezinezinye izinsuku ezintsimbi zokusetshenziswa.

·Umshado weDial, iphambili leYellow

1. Ukusetshenziswa kwezincwadi zingcindezelwa ngokusebenzisa iphuzi lemfino wegreese efanelekayo, ngeziphrofeshoni zokuhlawula ezifumanekayo ukuvumelanisa ukuthi akhule impendulo, kunye neziphrofeshoni ezifumanekayo zokuhlabelela ezincedwayo nokulandelana.

2. Ukusetshenziswa kwezincwadi zingcindezelwa ngokusebenzisa ikhompiyuthi lestele ekhoyo lokuhlola umlinganiso, iglass engavumele ifuthele, kunye nemilinganiso yencwadi yesikhombisi, kunye nokuthi inqanawa yenqanawe yasebhedlela yencwadi yesikhombisi.

Izimvumulo:

| Imodeli | STS-100 | STS-200 | STS-300 | STS-400 |

| Ububanzi bomax (mm) | 150 | 200 | 300 | 350 |

| Ububanzi(mm) | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 |

| Umvintisi(m/min) | 16 | 16 | 16 | 16 |

| Imoto(Hp) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Ukucorrection ukudiametri kwezikhono | Φ45 | Φ45 | Φ45 | Φ45 |

| Inani lesi-sayithutho esikhombisa | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) |

| Ukubuyisela okuphakamisiwe kwezinye zentloko | Φ34 | Φ34 | Φ34 | Φ34 |

| Amaphu anesayithutho | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) |

| Isilinganiso (m) | 1.6×1.0×1.5 | 1.6×1.05×1.5 | 1.6×1.15×1.5 | 1.6×1.2×1.5 |