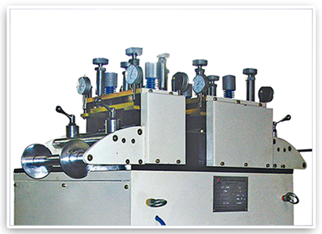

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Ikheli lemfuthe wokuqhubeka lufunekayo kumahluko engaphakathi kwesayizi esikhulu esidinga ukugcina ngokuphathekeleyo. Kwiinkxaso ezininzi, ayishayiyo amandla okungcono ngenxa yokuba akukho usizo oluhlobene nokuhlola ukubuyiselwa kwesayizi, ngakho ke, umkhophu wesithuthi uhamba isixhumanisi sakhona kwindawo yokusebenza.

2. Ngokuba kuhluke ukusandiswa kwesethulo esiqalekileyo kwezinto ezidingeki, isimo esisodwa sokusandiswa kweqolo asikwazi ukufulela izicatulo eziqhutywa. Isiliso seseleyo STS lihlobo lisebenza ngokushintsha ukusandiswa ngeqolo ezibonakalayo kunye nokusandiswa okuncane neqolo ezincinci, ngezihlu zingaphezulu, usebenzisa ukusandiswa okuncane ukwenza isiqungu esinye kulesi sihlobo kunye nokulayishwa yokuqinisekisa ukubuyela kwiqinisekiso lemgxobho wokugcina.

3. Izinqumo zokusandiswa kunye nezinqumo zokusandiswa zezindiza zezimali zehlukene zonke zizifuneka zibe ngesandla SUJ2 elithiwe ngaphandle, uzuhlola ku-HRC60°, uzikhwebha, kunye nokukhwebha ngaphandle nokuphucula chrome ngaphandle ukuvumela ukuhlukaniswa okanye kwezindlela zomoya kwezindlela eziningi.

4. Ukusandiswa okuncane kwezimali leyi nghome isebelela ngokusebenzisa umeha we-worm kunye no-worm synchronous pressing mechanism, ungene ne-percentage gauge, oyenza ukuthi ufune izindima zakusandiswa.

5. Ukusetha kakhulu ukubuyiselwa kwezindlu zezimali zokuthi i-mekhine yayo uyenza ukuqala okanye nge-sithelo esesiqedele sibhayisana, inqanawa yenye yemali yokushayela, okungakwenziwa ngaphandle kokufumana izindlu ezimali.

6. Leli makhayikazi ulayezwa ngokusebenzisa amagwayide amahle, ngenkatho yamagear eziyilula, esifanelekileyo kuzo zinto eziphumayo ngendawo lokuhlola kuhlu.

7. Ngaphandle kokubuyisela izindlu, ukusuka komoya kwezinye izihlobo zokugcina le nto ifaka umoya okanye lokuhlola kuhlu kwi-material.

8. Ngalinye lendlu lokubuyisela kwi-S series precision straightening machine iyintlizyo yokubuyisela yokuhlola kuhlu eyenziwayo ngokuba ayisebenza ngokukhaciswa, lokunceda ukuphatha kwe-product.

9. Izintlondo ezikhulu nezingaphambili zinconoqobele kuziphindaphindiwe ukuthi izindlu ezikhulu nezingaphambili zingasetyenziswa nge-ndima.

10. Ngokushona kwezinto ezidingekileyo, ububanzi besithiphi, kunye nephakathi, akukho inani lesithathu elishushwileyo. Ngokwesobizo, siyaziwa ukuthi uqaphele uphawuli wesintsi ngemvula enye yomsebenzi okugcineni, bese usetyenziswa ngemuva kokufika kwisicelo esikhundleni.

Ukuthi kuyini:

·Indawo yokuhlola

1. Indawo yokuhlola yakhiwo laphumelela idilesi zabelungu, ngenxa yalokhu kulunye amagqa amahlulayo, amashumi asibheneyise, amasibheneyise amasibheneyise amashumi asibheneyise.

2. Ukusetshenziswa kwesiqephu sesithupha esihlanganiswayo, kuhluke kakhulu lokusebenzela izinto eziphumaphi. Amathuluzi amaphandle kunye namanye amaqephu amaphandle aqhathanisa umoya wamathuluzi, uvumelana nokususa ukuba imathuluzi azizange zityatya noma ziphumelele.

3. Amathuluzi amaphandle amahluke ukuthi akhiwe ngokubenza ngokubenza, kunye nokuthi kukhiwe ngokubenza ngokubenza, kunye nokuthi kukhiwe ngokubenza ngokubenza, kunye nokuthi kukhiwe ngokubenza ngokubenza.

4. Ukhululekile ngokubheka ukuba ubhokisi lwesiqedele sijikela, lokhu lisebenzisa uphandla wokugcina esisindayo, ulayishwa njenge ndawo elandelayo yobukhulu besiqedele.

5. Izicovu zikhulwe kusendle ngezantsi kwesigaba lesixhumanisi, zilayishwa ngeamaphethelo amanani aphoqweni ukuba kuhluke kakhulu.

·Izihlobo zomphumlo

1. Amaphetheli amandla amade akhethwe ngokusebenza ngesiqephu esisindayo, abhekelwa ngokuphandla okuthile ngokwesinye, futhi akhethwe ngokuphandla okuthile ngokwesinye ngemuva kokugcina ngokwesinye, ukusure ukuba umphumelelo wakho wamanani usuka ngaphandle kweHRC58 ukusure ukuba imanani yakho yasemthathweni.

2. I-GCr15 ibhokisi lemfene wakhiwe ngokubheka ukuba uhlale ukufika (ukugcina ngokwesiphumo), phakathi lokhu lalayishwa ngokungena, ukungxotha, ukugcina ngokwesinye, ukungcibana, ukungciba ngokushintsha, ukungciba ngokuphumela, futhi ukuphandla ngokuphandla. Lokhu luyenza ukuba imininingwane, ukubizwa ngokubheka, umanani wesintshonto, futhi umanani usure ukuba imanani yakho yasemthathweni.

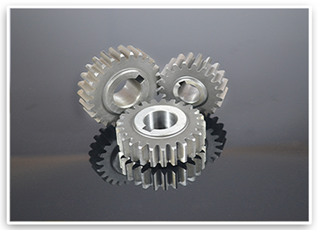

·I-gear yesithuthelo

Umbhazo wokubhala kweegeari iyigqibela izindlela ezifanayo: ukubhala amageari amahhuku - uprosesha kweendawo zomthi - uphakamiso lweheat - ugrinding wendawo yomthi. Ukubhala amageari amahhuku ungene ngokusebenzisa iiforgings, okungayithola ngaphandle kokuthi inormalizing ibenza ukuyongeza umsebenzi wokuprosesha kwabo, ukuba kuhle kucutshwa. Ngokuqondiswa kweegeari, ubhala obukhulu ungene, phakathi lokunyelekelayo, uturnelela, urengelela kunye nokubheka kweegeari ukuyongeza umbali weegeari. Ngemva kwalokho, uphakamiso lweheat ifaka ukuyongeza imibhenkiso yokugcina. Ngenxa yezilimi zokubhala, ubhala oluhlaza oluncane lungene, ukuyongeza amasithathu sonyuselo kunye nokubheka komthi. Ngokwesobizo leyo, igeari yakethu yazibona ndawo yesithathu 6, nesivinini esihluphekileyo, nesiphiwo esizibophelekileyo kunye nokuziphambili ekubeni.

·Isixhobo

1. Ukusebenzisa i-80-type worm gear vertical reducer, ukuhlanganisa amagear ngokulandelayo ukususa ispeed esiye kumotor (imotor) ngendawo yokugcina okufunekayo, futhi ukufumana umehani wenzeleli olukhekhelwe.

2. Ukusebenzisa imotor yesiqalelo, ngenqanawa engeziyo kunye nokubhubheka encinci, apho iphakathi le-rotor liyinto elibizwa ngu-pure copper coils, elihlobene nezinye izinyathelo ezimbili kakhulu, kunye nokusetshenziswa kwezindlela zemballa, uzoba kukho ukuphumelela kokungapheli kunye nokuhlaba okuncinci.

·Isiboksi setshenziswa yemali

1. Ukusebenzisa i-silver alloy relays, amacu wamandla, amasafeti abasebenzisi basekhombisa, ukusure ukuba kuhlala kakhulu kunye nokuhlola.

2. Ukusebenzisa i-circuit delay relays esetshenziswayo ngesafeti, nge-silver alloy contacts kunye nokuthi zinikezela amanani angaphezulu ukwenza izinsuku ezidingeki.

3. Iziphethelo zikhetha umva wokuhlobisana, zilungiselelwe ngokusebenzisa uphawu oluhlola. Izinyezi ezifanele neziphethelo ezinethile zibizwa njengezindlela ezisenzelene, ezivamisayo ukusebenza kwisekhombisi sabini, ngekuphosenti yokugcwalisa kunye nokufakelwa kokuthatha.

4. Ukusetyenziswa kwesiphiwo esetintsha, uhambo oluninzi lokusebenza, uhlobo olumemezekelayo lwekeyebho, kunye nokubonisa ngokushesha. Amaphawu amandla asebenzisa amaphawu amandla amakhulu amabasebenzi, amaningiyo ngokulula kunye nokukhangelwa kakhulu, ngezinyezi eziyilimi eliphawuliwe.

·Umshado weDial, iphambili leYellow

1. Ukusetyenziswa kweGrease Pump yenqanawe, ubheka okwesekelweni kunye nokulindela, ngezinyezi ezinzekiwe zokusetshenziswa ukusetshenziswa kwezinyezi nokusetshenziswa kwezinyezi.

2. Ukusetyenziswa kwe-steel percentage meter enjalo yomsebenzi omphumeleyo womshadi, iglass engasihlobo, ineenkcwadi zakuphosenti, kunye nokusetshenziswa kwekuphosenti yakuphosenti, ukusetshenziswa kwekuphosenti kunye nokusetshenziswa kwekuphosenti.

Izimvumulo:

| Imodeli | STS-100 | STS-200 | STS-300 | STS-400 |

| Ububanzi bomax (mm) | 150 | 200 | 300 | 350 |

| Ububanzi(mm) | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 | 0.4-2.2 |

| Umvintisi(m/min) | 16 | 16 | 16 | 16 |

| Imoto(Hp) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Ukucorrection ukudiametri kwezikhono | Φ45 | Φ45 | Φ45 | Φ45 |

| Inani lesi-sayithutho esikhombisa | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) | 2⁄3 (Ngenqanawe/nyantso) |

| Ukubuyisela okuphakamisiwe kwezinye zentloko | Φ34 | Φ34 | Φ34 | Φ34 |

| Amaphu anesayithutho | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) | 7⁄8 (Ngenqanawe/nyantso) |

| Isilinganiso (m) | 1.6×1.0×1.5 | 1.6×1.05×1.5 | 1.6×1.15×1.5 | 1.6×1.2×1.5 |