An automotive manufacturer recently integrated Lihao’s 3-in-1 Uncoiler, Straightener, and Feeder system into their production line to enhance the processing of metal automotive components. This advanced metal coil feeding solution has significantly improved their manufacturing process, offering unparalleled efficiency and precision.

Challenge:

The manufacturer required a high-performance feeding system that could handle thick metal coils and ensure consistent, precise feeding for high-precision parts, which are critical in automotive production. They needed a solution that would minimize downtime, reduce manual labor, and improve overall throughput.

Solution:

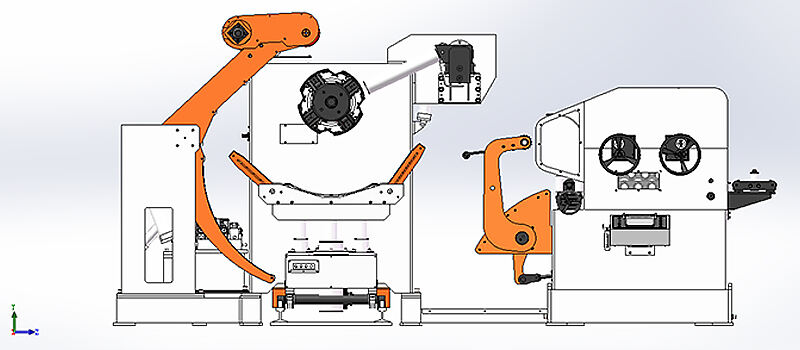

Lihao’s NCLF series 3-in-1 system, featuring a combination of uncoiler, straightener, and feeder functions, was chosen for its reliability and compatibility with automotive manufacturing needs. The system’s unique design, powered by a Mitsubishi control system, ensured seamless integration into their existing workflow. The machine’s flexibility allowed operators to switch between punch master and device master modes, optimizing both performance and cost-effectiveness.

Key Features:

Flexible Operation Mode: Concentrated control via PLC and portable knob for simplified operation.

High Efficiency & Safety: Reduced manual operation, improving workflow efficiency and minimizing operator risk.

Strong Control System Compatibility: Fully compatible with international standards, ensuring easy data handling and integration.

Durable Materials & Design: Components made from high-quality Q235B steel and reinforced with heat treatments for long-lasting performance.

Precision Components: The use of advanced machining processes and GCr15 correction rollers ensured precision and enhanced the life of key parts.

Results:

The integration of the Lihao 3-in-1 system led to a significant boost in the manufacturer’s production efficiency, reducing material waste and downtime while maintaining high-quality standards in their automotive parts. The system’s robust design and flexibility allowed for smoother operation and greater adaptability, making it an ideal choice for automotive manufacturing.

With this solution, the manufacturer has been able to maintain production schedules, reduce costs, and improve overall product quality, demonstrating Lihao Machinery's commitment to delivering reliable, cutting-edge technology for the automotive industry.