Slitting lines are special machines that are used to cut big metal sheets into smaller pieces. These are really important machines that are used by a lot of various businesses, from car companies, which need to create a lot of different parts for the...

VIEW MORE

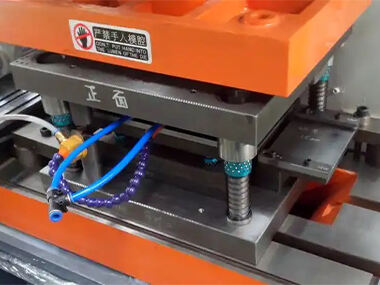

Pursuit of efficiency, accuracy, and safety in production works tirelessly and remodels the industrial sphere. A rather silent revolution is proceeding in the sheet metal industry and component production: the gradual increase of pneumatic punch pres...

VIEW MORE

The choice of optimum equipment to use in processing coil stock is highly essential to a stamping or fabrication operation. There are in fact two main solutions to occupy this area amongst the integrated 3-in-1 feeder, and the separate split uncoiler...

VIEW MORE

What Do You Know About the Types and Structures of Pneumatic Punches? There is no limit to the number of manufacturing, and fabrication systems in which pneumatic punches serve as workhorses. With compressed air, they provide quick, dependable blast ...

VIEW MORE

In such a tough industry of metal construction where tolerances are narrow and quality an essential requirement, the straightening machine works as a significant gatekeeper against bent metal and any reject which can prove expensive. However, with in...

VIEW MORE

When stamping high volumes of stainless steel, the 3-in-1 feed line, which combines feeding, straightening and guiding functions in one, coherent unit, is an important element. The effectiveness of its work directly influences the quality and materia...

VIEW MORE

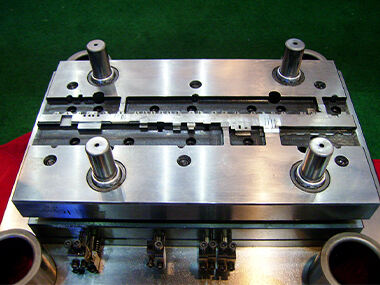

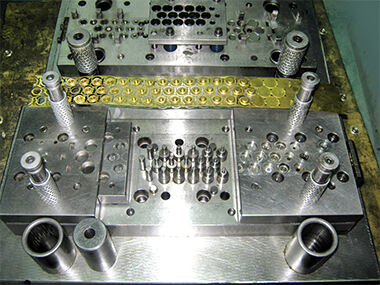

Modern manufacturing relies on precision metal stamping dies that are the unsung heroes. They turn plain metal sheets into complex components with high volumes that are everywhere we turn, including electronics and appliances, automotive and medical ...

VIEW MORE

Selecting the correct punch press is one of the most important decisions you make that affects the productivity, efficiency, and profitability of your shop long term. However, purchasing this is full of possible misunderstandings that can result in e...

VIEW MORE

Selecting the metal to make your mold is one of the critical initial decisions that will affect work production, quality of parts, tool life, and cost. Choosing the one that is the best depends on the knowledge about the inherent features of various ...

VIEW MORE

Consistent, high-accurate stamped components requires a careful die debugging. Once work pieces come out of tolerance, have visual defects, or early wear to compound tools, it is necessary to follow a more systematic process. These are essential note...

VIEW MORE

To manufacturing companies that depend on stamping, the question is: how many more uses can this die have? It may not make a million dollars question (not literally, of course!), but it certainly makes a difference. Until now, unfortunately, there is...

VIEW MORE

One of the classical elements of the modern fabrication industry is a punch press which is unique in terms of its exceptional adaptability. Quite unlike some other machines with only one trick, it is capable of coping with an immeasurable range of me...

VIEW MORE