JH21 Series C-Frame Double Cranks Press

Product Description

1. Product Features

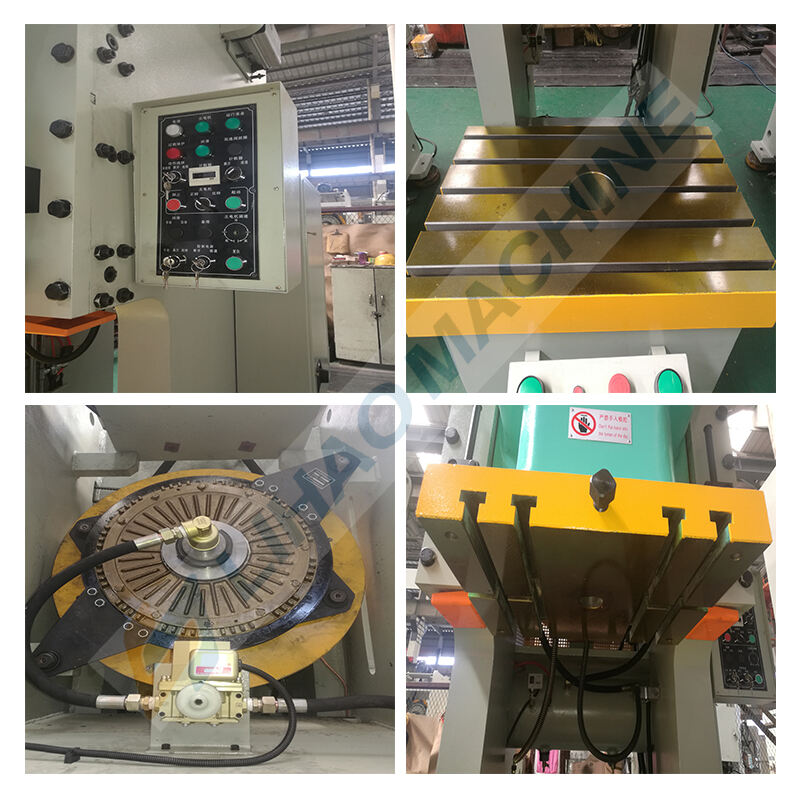

1. This series of machine tools is a high performance punching machine with an open fixed table, which in-creases the throat depth.

2.The fuselage is welded with integral steel plate to remove internal stress. It has high strength and steel degree, and can flexibly change the depth of throat

3. Crankshaft longitudinal structure, compact structure beautiful appearance.

4. Rectangular hexahedron lengthening guide rail, high guiding accuracy.

5. Combined pneumatic friction clutch/brake, combined smooth, low noise.

6. JH21S adopts hydraulic overload protection device. while JF21S adopts steel safety device to prevent damage to machine tools caused by overload.

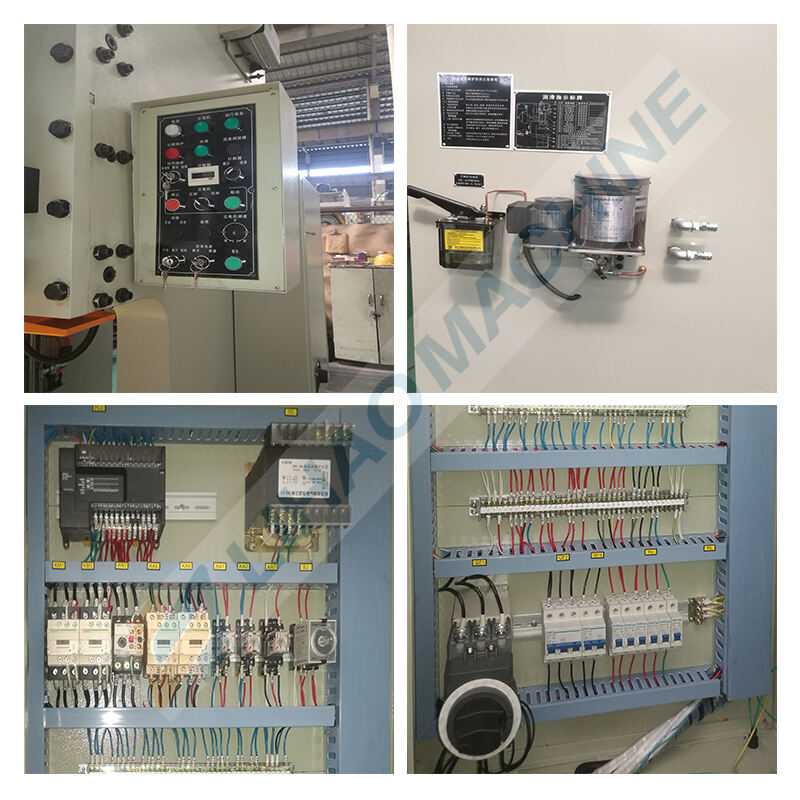

7. The circuit is controlled by PLC, and the air circuit by safety double valve, which is sensitive, safe and reliable, with single, inching, continuous operation specifications, in line with the safety standard of punch.

8. The sliding block adopts pneumatic balance device to improve the smoothness and precision of the machine.

9. The machine adopts automatic thick oil lubrication with fixed time, fixed point and fixed quantity, which is suffi-cient, uniform and reliable.

10. Optional automatic feeding device, photoelectric pro-tection device, die cushion, etc.

2. Applications

This open-type press with fixed table is press machine of general use intended for stamping operations such as stamping plate materials. It is fit for punching, cutting, bending, folding and shallow drawing, and is widely used in various industries such as watch making, toys, utensils, communication apparatuses, meters & instruments, electric motors, tractors, auto making, metallic tools and radio components.

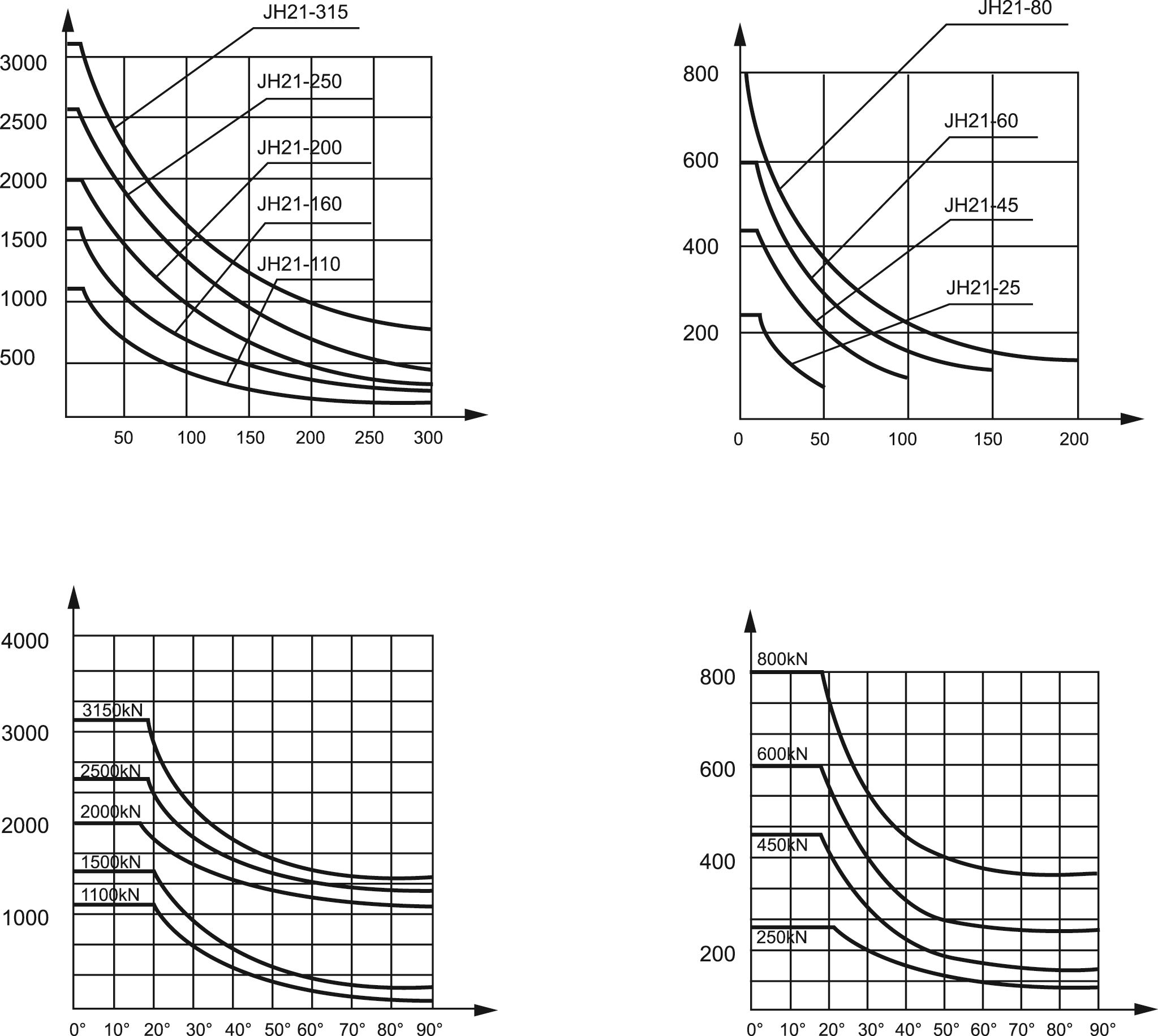

Operating capacity of the machine: to use the machine properly and keep it under the optimum operating conditions, it is recommended 70% of the permitted value be adopted as the workload. Please check the following things before using the machine.

1.1 Load capacity: This press machine is not fit for coining operation. Make sure the workload is below the nominal force.

1.2 Torque capacity: The press capacity of the machine changes to the position of the slide block. The “press curve” shows the changes of the press capacity. The workload must be lower than those shown on the curve.

3. Details

| Specification | Unit | JH21-25 | JH21-45 | JH21-60 | JH21-80 | JH21-110 | JH21-125 | JH21-160 | JH21-200 | JH21-250 | JH21-315 | JH21-400 |

| JF21-25 | JF21-45 | JF21-60 | JF21-80 | JF21-110 | JF21-125 | JF21-160 | JF21-200 | |||||

| Capacity | Ton | 25 | 45 | 60 | 80 | 110 | 125 | 160 | 200 | 250 | 315 | 400 |

| Rate tonnage point | mm | 3 | 4 | 4 | 5 | 5 | 5 | 6 | 6 | 7 | 7 | 8 |

| Stroke | mm | 80 | 120 | 140 | 160 | 180 | 180 | 200 | 250 | 250 | 250 | 280 |

| Stroker per Minute | s.p.m | 100 | 80 | 70 | 60 | 50 | 50 | 45 | 45 | 40 | 40 | 35 |

| Die height | mm | 250 | 270 | 300 | 320 | 350 | 350 | 400 | 450 | 500 | 500 | 530 |

| Slide adjustment | mm | 50 | 60 | 70 | 80 | 90 | 90 | 100 | 110 | 120 | 120 | 120 |

| Depth of Throat | mm | 210 | 225 | 270 | 310 | 350 | 350 | 390 | 430 | 450 | 450 | 490 |

| Distance betweenuprights | mm | 450 | 500 | 560 | 620 | 660 | 660 | 720 | 900 | 980 | 980 | 1050 |

| Slide area | mm | 360x250 | 410x340 | 480x400 | 540x460 | 620x520 | 620x520 | 700x580 | 880x650 | 950x700 | 950x700 | 1000x750 |

| Shank hole | mm | ∅40x60 | ∅50x60 | ∅50x60 | ∅50x60 | ∅70x80 | ∅70x80 | ∅70x90 | ∅70x90 | ∅70x100 | ∅70x100 | ∅70x100 |

| Bolster area | mm | 720x400 | 810x440 | 870x520 | 950x600 | 1070x680 | 1070x680 | 1170x760 | 1390x840 | 1500x880 | 1540x880 | 1700x940 |

| Size opening in the table | mm | 150 | 150 | 150 | 150 | 160 | 180 | 200 | 200 | 200 | 200 | 200 |

| Distance from worktable to ground | mm | 780 | 800 | 900 | 900 | 900 | 900 | 900 | 1000 | 1000 | 1000 | 1020 |

| Main motor | kw.p | 2.2x4 | 5.5x4 | 5.5x4 | 7.5x4 | 7.5x4 | 11x4 | 15x4 | 15x4 | 22x4 | 30x4 | 37x4 |

| Slide adjust device | HP | manual operation | electrial driving | |||||||||

| Air pressure | kg/cm2 | 6 | ||||||||||

| Presses precision | GB/JIS 1 class | |||||||||||

| Presses dimension | mm | 1520x1060x2120 | 1620x1130x2340 | 1690x1160x2650 | 1870x1170x2810 | 2020x1315x2985 | 2020x1315x2985 | 2325x1450x3250 | 2580x1690x3810 | 2820x1710x3900 | 2880x1750x3920 | 3150x1940x4320 |

| Die cushion capacity | Ton | 4.5 | 4.5 | 6 | 6 | 8.5 | 8.5 | 8.5 | 11.5 | 15 | 15 | 15 |

| Stroke | mm | 50 | 50 | 60 | 60 | 70 | 70 | 80 | 80 | 90 | 90 | 90 |

| Die cushion effective area | mm2 | - | 300x230 | 350x300 | 450x310 | 500x350 | 500x350 | 650x420 | 710x480 | 710x480 | 710x480 | |