We use a combination of advanced manufacturing capabilities and applied best practices to produce genuine craftmanship and quality products for our customers. Our metal stamping equipment allows us to create highly precise products with extreme detail that can be scaled to different sizes, based on the needs of our customers.

Contact-us

In the realm of metal hinge manufacturing, precision, efficiency, and reliability are paramount. Our company, a leader in industrial machinery, embarked on a journey to revolutionize hinge production. By integrating cutting-edge technology and streamlined processes, we aimed to enhance productivity while maintaining uncompromising quality standards.

Overview:

Our initiative centered on the design and implementation of a state-of-the-art metal hinge manufacturing production line. This production line aimed to optimize every stage of the manufacturing process, from raw material handling to final inspection, ensuring seamless operations and superior hinge quality.

Challenges:

Prior to the implementation of our production line, our manufacturing process faced several challenges. These included:

- Inefficient workflow: Manual processes led to bottlenecks and delays, hindering production efficiency.

- Quality inconsistencies: Variations in manufacturing techniques resulted in inconsistent hinge quality.

- Limited capacity: The existing setup lacked scalability to meet increasing market demands.

- High operational costs: Manual labor-intensive processes increased production costs and reduced profit margins.

1.Production Line Features

We offer comprehensive production lines, complete with stamping molds, covering the entire manufacturing process from raw material to finished product.

2.Production Process

Sheet Metal Coil-Uncoiler-Straightener-Feeder-Press Machine-Mold-Product

3.Solution

To address these challenges, we devised a comprehensive solution focused on automation, precision, and scalability.

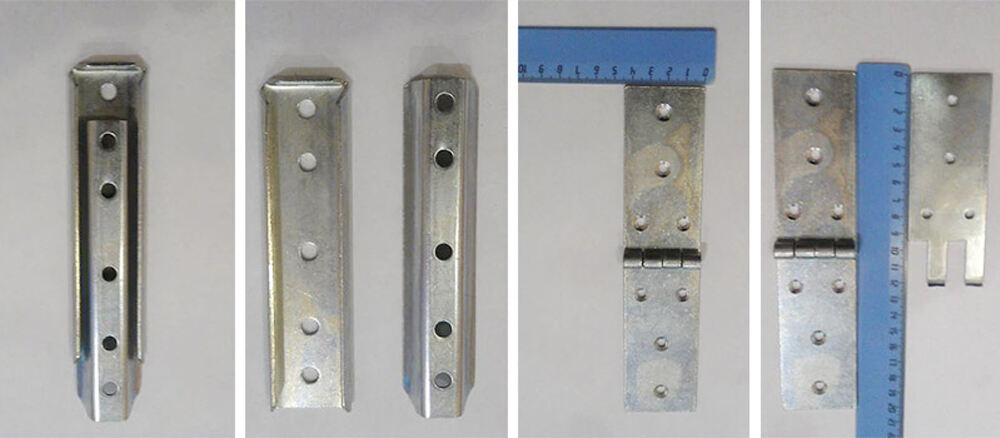

Samples provided by the customer

4.Details of Machine

- TGL Series Decoiler & Straightener 2 IN 1 Machine: Combines decoiling and straightening functions into one, saving space and facilitating easy operation.

- NCF Servo Feeder: Ideal for processing and feeding materials of different thicknesses and lengths, ensuring versatile production capabilities.

5.Compatible Materials:

Our equipment is designed to handle various types of metals, providing flexibility for different manufacturing needs.

6.Video

Hinge Production Line Installation Video: Click here

Hinge Production line Working Video: Click here

7.Conclusion

The implementation of our metal hinge manufacturing production line yielded significant results:

-Enhanced Efficiency: Automated processes streamlined production, reducing cycle times and increasing output by 40%.

-Consistent Quality: Robust quality control measures minimized defects, ensuring every hinge met precise dimensional and performance standards.

-Scalability: The modular design facilitated seamless expansion, enabling us to scale production to meet growing market demands.

-Cost Savings: Reduced reliance on manual labor and optimized processes led to a 30% reduction in production costs, improving overall profitability.

In conclusion, our metal hinge manufacturing production line exemplifies innovation, efficiency, and excellence in industrial manufacturing. By embracing automation, precision engineering, and scalable design, we have redefined the standards of hinge production, setting new benchmarks for quality, productivity, and cost-effectiveness in the industry.