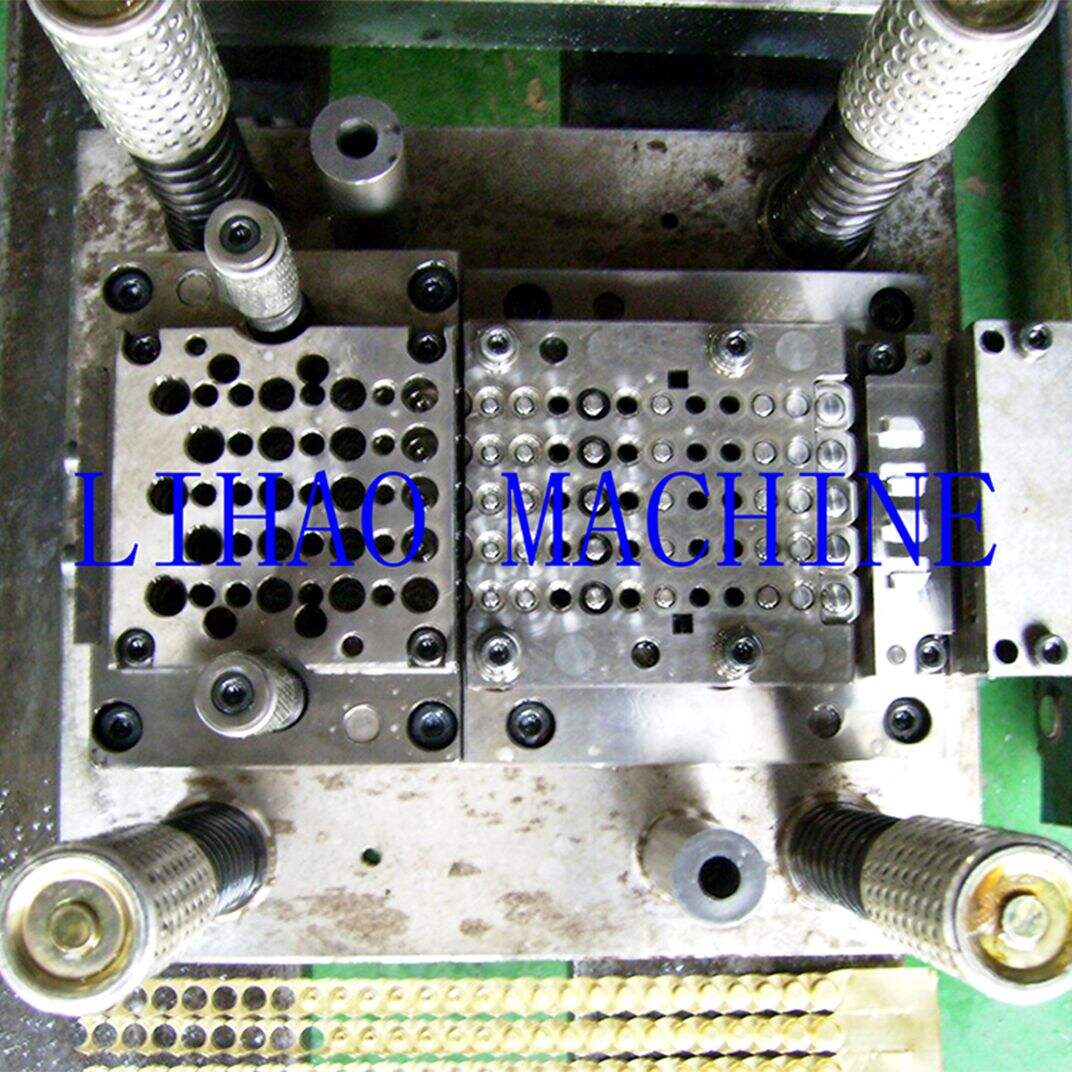

Metal Stamping Mould progressive stamping die Punching Die Press Mould Deep Drawing Mould Press Tool Die Sets

Product Description

Features

1.Use for process procedure more than 1 various products punching, various products widely used in mobile, tooling, commodity, etc. industry production.

2. It operates with a high-speed press machine at a punching speed of over 200 strokes per minute (SPM), achieving up to 10 production cycles per day. By using general dies and presses for mass production, it ensures consistent product quality and minimizes shape deviation even when multiple dies and presses are used simultaneously. This also reduces the facility requirements, thereby saving factory space.

3. It saves more than 10% of material.

4. The use of coil material and an automatic feeder in production significantly reduces labor intensity and costs.

5. Different models can be designed according to clients' specific requirements for product shape, size, and pattern.

Technical parameters:

| Details Description | Metal stamping mold | |||

| Design software | ProE, CAD | |||

| Cavity | Single-cavity ,Multi-cavity | |||

| Main Mould Plate material | SKD11 | |||

| Main Insert and trim material | DC53 | |||

| Leader Pin Bushing | High Precision | |||

| Punch Processing | Centerless grinding | |||

| Mold plate and insert processing | WEDM-LS | |||

| Insert precision | 0.01mm | |||

| Mold plate flatness | 0.02mm | |||

| Mould Life | 30,000,000 shots,etc.(except wearing part ) | |||

| Wearing part | Trim ,Pin, Spring | |||

| Delivery time | 3 to 6 weeks (3 weeks for prototype mold) | |||

| Package | Wooden Box, Carton | |||