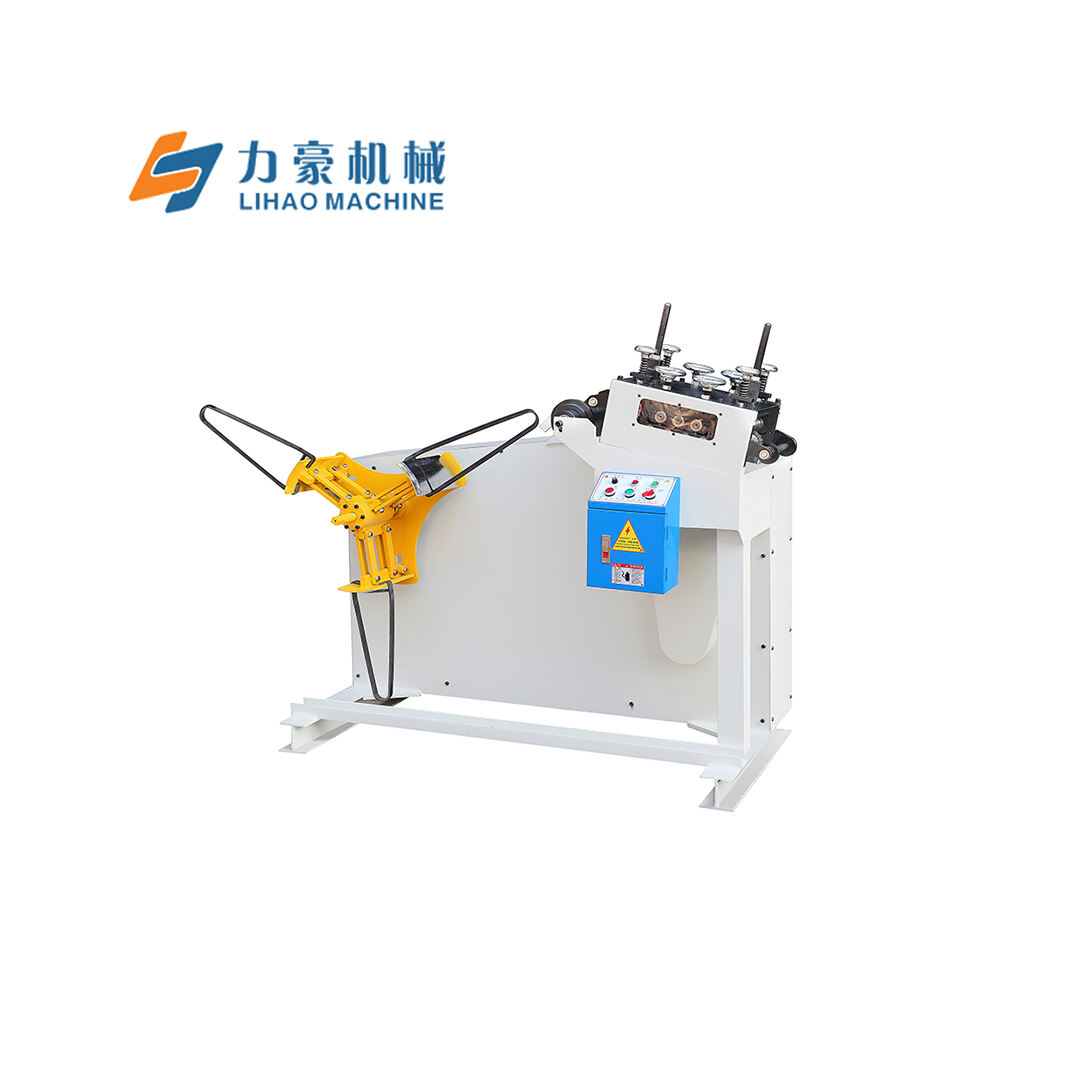

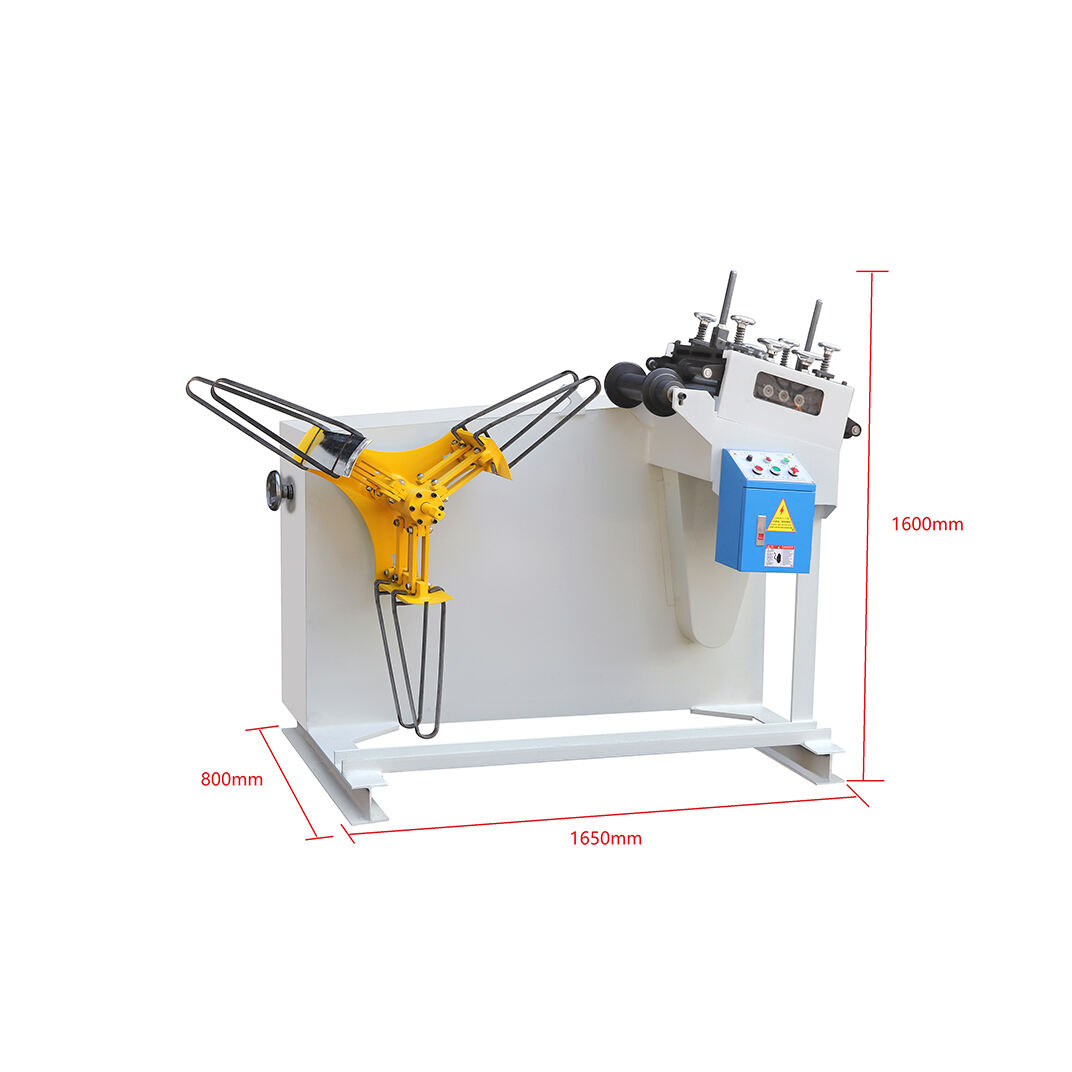

New GO Series Straightener Cum Uncoiler 2 in 1 Metal Coil Feeding System for Sheet Thickness: 0.4mm~2.5mm

Share

Uncoiler/sraightener machine

Save space

High precision

Product Description

Decoiler Cum Straightener

Features:

1. Combining the decoiler and straightener into one unit maximizes factory space utilization.

2. The decoiler features a cantilever beam design, with frame components cut from laser plasma for high precision and excellent equipment interchangeability.

3. The straightener employs a parallel roller design with four-point fine-tuning for precision leveling, ideal for processing high-precision products. Four independent pressure adjustments on the feed wheels prevent material deviation.

4. Solid bearing steel is used for the straightening wheels, electroplated for increased durability with a surface hardness exceeding HRC58.

5. All parts are manufactured using NC and CNC machining, ensuring high interchangeability.

6. The equipment is assembled using modular structures, facilitating assembly and part replacement by general technical workers, thus significantly reducing maintenance costs.

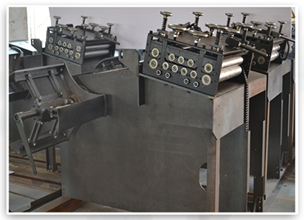

·Straightener head

1. The machine head adopts a parallel roller design with a total of 7 straightening rollers (3 on top and 4 on the bottom).

2. Four-point micro-adjustment is employed, making it more suitable for processing high-precision products. Four-point independent pressure adjustment is utilized for feeding and unloading, effectively preventing material deviation and deformation.

3. The material support rollers utilize passive galvanized rollers, integrally formed for durability. The surface is resistant to scratches and wear, and they feature mechanical bearings for flexible and long-lasting rotation.

4. Cast iron handwheels are used, featuring surface electroplating treatment, representing the most traditional type of handwheel.

5. Protective covers are installed on both sides of the transmission part for protection, equipped with viewing windows for convenient observation.

·Straightening roller

1. The straightening rollers are made of solid bearing steel, undergo thickened electroplating treatment after intermediate frequency heating, with a surface hardness not less than HRC58, ensuring material durability.

2. GCr15 round steel is forged, subjected to preheating treatment (spheroidizing annealing), followed by turning, milling, intermediate frequency treatment, coarse grinding for cold stabilization, precision grinding, and finally electroplating. This maximizes precision, concentricity, surface smoothness, and hardness, extending the service life of the straightening rollers.

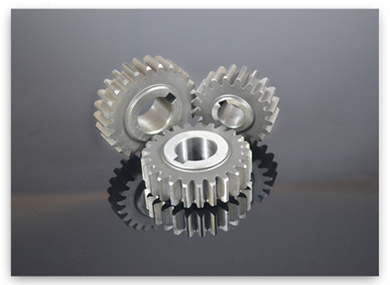

·Drive gear

The gear manufacturing process involves the following stages: rough gear cutting, gear surface machining, heat treatment, and gear surface finishing. Rough gear cutting, primarily utilizing forging, involves normalizing treatment to improve its machinability for cutting purposes. Following the gear design drawings, the gear undergoes rough machining, followed by semi-finishing processes such as turning, rolling, and tooth insertion, to achieve basic gear formation. Subsequently, heat treatment is applied to enhance mechanical properties. As per the design specifications, the final stage involves precision machining and refinement of gear standards and tooth profiles. Through these processes, our gears attain a grade 6 rating, exhibiting high wear resistance, high strength, and extended lifespan.

·Frame part

1. This equipment adopts a combined integral design of the material rack and straightener, enhancing site utilization.

2. The material rack is designed with a cantilever beam, and all frame plates are cut using laser plasma cutting, ensuring high precision and excellent equipment interchangeability.

3. All components are machined using numerical control (NC) and computer numerical control (CNC) processes, ensuring good interchangeability.

4. The overall design employs an assembly structure, allowing assembly and replacement of equipment parts by general technical workers, facilitating quick and convenient maintenance, thus significantly reducing maintenance costs.

·Electric control box

1. Adopting silver alloy relays, all-copper coils, flame-retardant safety bases, ensuring long-lasting durability.

2. Utilizing safety-protected adjustable circuit delay relays with silver alloy contacts, multiple degree discs, meeting various delay ranges.

3. Switches employ sliding contacts with self-cleaning function, featuring separately insulated structures for normally open and normally closed contacts, capable of working with opposite poles, equipped with anti-rotation positioning and anti-loosening mounting pads.

4. Employing self-resetting push buttons with lightweight operation, moderate stroke, and modular structured contact points using ketone-based composite materials, exhibiting strong electrical conductivity, capable of carrying large currents, with a lifespan of up to 1 million cycles.

·Power part

1. Utilizing an 80-type worm gear reducer, employing the gear speed converter to reduce the rotational speed of the motor to the desired level and obtain a larger torque mechanism.

2. Employing a vertical motor with low vibration and noise, featuring a stator portion made of pure copper coils, with a lifespan ten times longer than ordinary coils, equipped with ball bearings at both ends, resulting in low friction and temperature.

|

Model |

GO-200 |

GO-300 |

GO-400 |

|

Width |

200mm |

300mm |

400mm |

|

Thickness |

0.4~2.5mm |

||

|

Coil inner dia. |

450~530mm |

||

|

Coil outer dia. |

1200mm |

||

|

Loading weight |

500kg |

800kg |

1000kg |

|

Straightening roller Qty |

7pcs(3up / 4 down) |

||

|

Expand type |

Manual expansion |

||

|

Speed |

16m/min |

||

|

Straightener adjustment |

Four points floating adjust |

||

|

Induction type |

Touching type |

||

|

Retainer |

manual“A”shape rack |

||

|

Motor |

1hp*4p |

2hp*4p |

2hp*4p |

Straightening Performance

|

Thickness / model |

GO-200 |

GO-300 |

GO-400 |

|

0.4 |

200 |

300 |

400 |

|

1.5 |

200 |

200 |

200 |

|

2.0 |

150 |

150 |

150 |

|

2.5 |

100 |

100 |

100 |