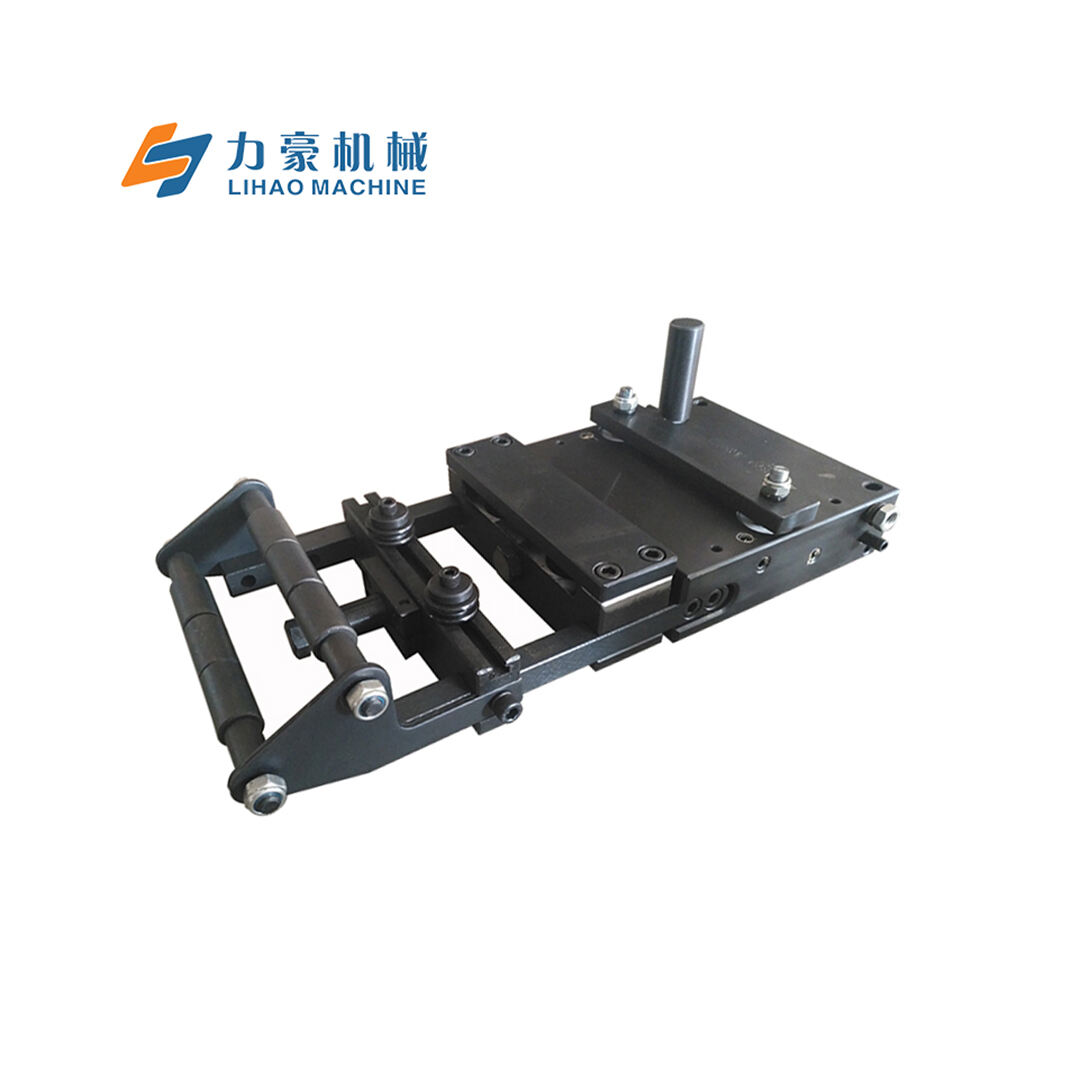

Pneumatic Feeder Series ( 1C~11C ) Metal Coil Air Feeder Conveyor Material Width: 50mm~450mm Thickness: 0.5mm - 3mm

Share

Rigid & Strong Structure

High Pitch Accuracy

Low Air Consumption & Inexpensive

Simple Installation

Product Description

Air Feeder

Features:

1. High efficiency, low frictional force of the valve, increasing rotational speed efficiency.

2. All sealing components adopt imported brands from Japan.

3. The new floating rod adopts a two-position three-way valve structure, completely solving the problem of air leakage caused by the floating rod position.

4. Low failure rate, made of 45-degree steel through CNC precision machining, less prone to issues.

5. Extremely small footprint, simple structural design, easy installation and operation.

6. Stable operation with high feeding accuracy.

7. Compact overall structure, high precision, fast speed, aesthetically pleasing and practical; all machines undergo rigorous testing before leaving the factory.

8. Customizable in any size and length.

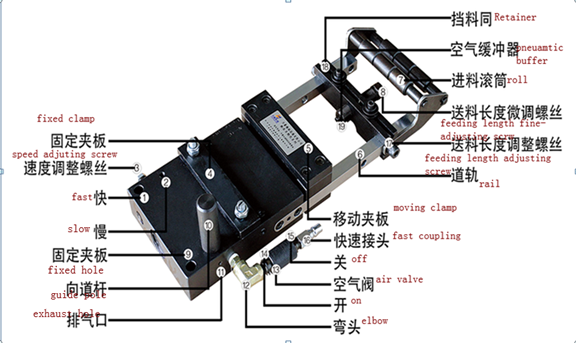

Product Description:

·Main process

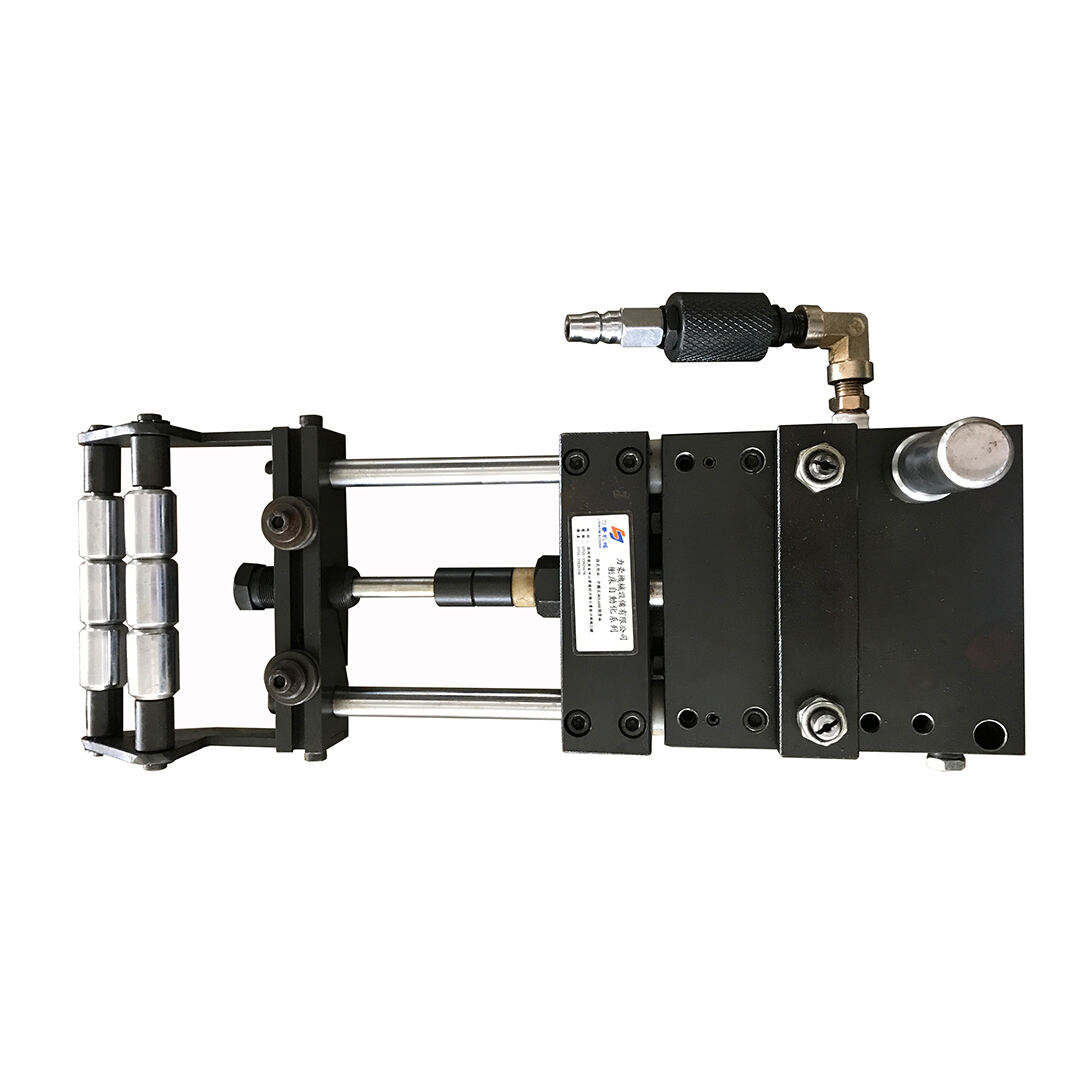

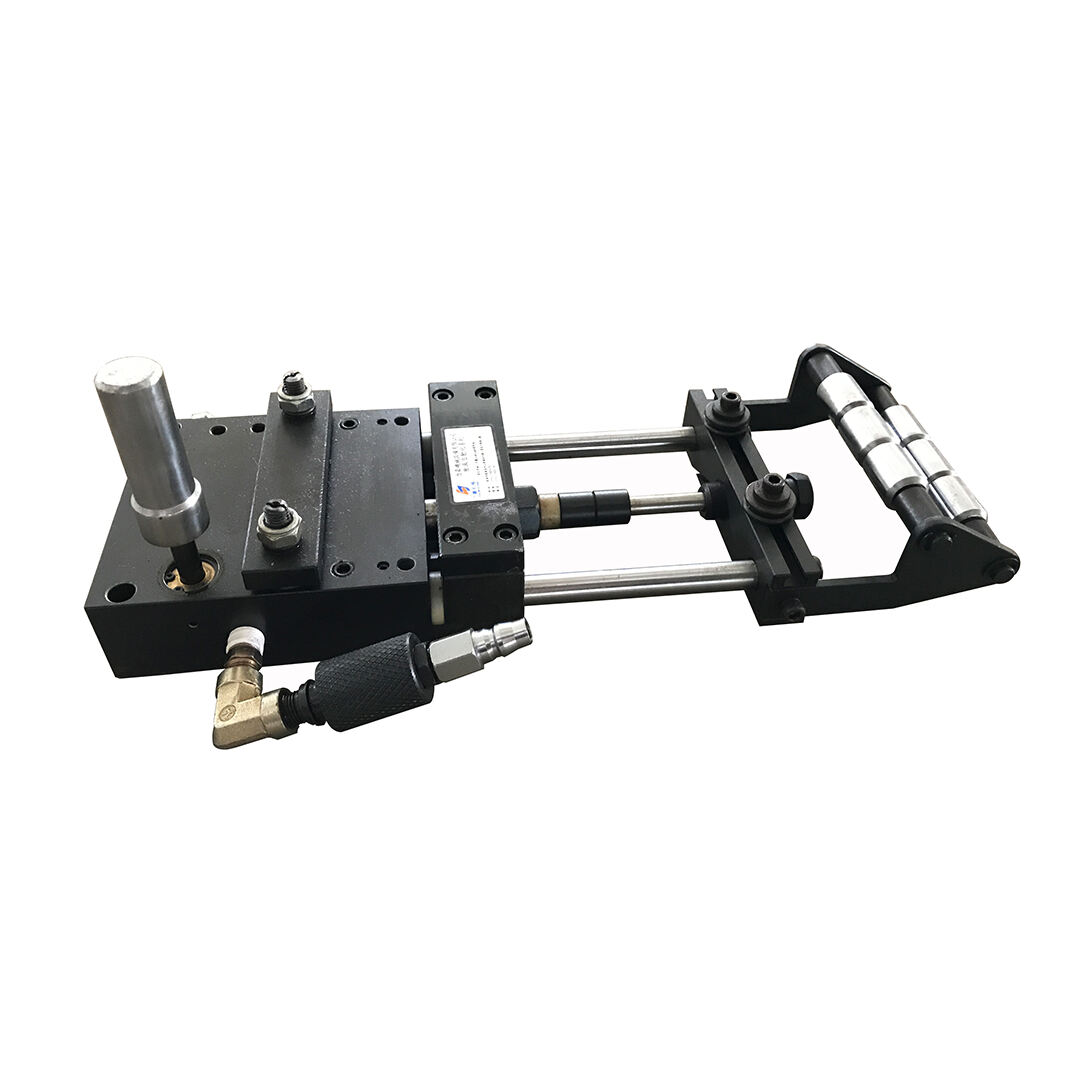

1. The main body's central large hole is ground and then electroplated, ensuring better cylindricity and straightness of the central large hole, thus facilitating smoother movement of the central shaft.

2. After processing, the main body undergoes anti-rust treatment uniformly, followed by ultrasonic cleaning before assembly to ensure that the machine does not malfunction due to processing residues.

3. The guide rail is made of high-strength steel, undergoes heat treatment, and then receives a hard chrome plating treatment. The contact area between the moving body and the guide rail undergoes precision grinding, making the movement of the moving body more flexible and smooth.

·Fittings

1. The replaceable directional valve adopts a large rounded corner structure, with the inner hole subjected to mirror polishing treatment, greatly enhancing the feeding speed of the feeder and the service life of the sealing ring.

2. Two sets of pneumatic buffers are employed to automatically absorb the inertia impact during the operation of the air feeder, effectively reducing vibration and noise.

3. High-strength oxygen-resistant adhesive is used for all screw installations, ensuring they do not loosen due to prolonged use-induced vibration and achieve excellent sealing effects.

Equipment models

·Standard Type E Electromagnetic Valve

Suitable for situations where the stroke of the punch is either too short or too long for feeding.

·Standard Type R Electromagnetic Valve

For situations requiring high-precision feeding, the electromagnetic valve can be used to release and correct errors in the fixed clamp plate.

·Left and Right Zigzag Type

Suitable for various types of part processing, can save more than 1/2 of the material. Support uses vertical bearings, combined with round bar sliding, noiseless, high wear resistance, light load, rapid displacement, and shortened feeding time. Utilizes electronic control, allowing selection of feeding time. Simple operation, easy maintenance, high precision.

Specification:

|

model |

|

AF-1C |

AF-2C |

AF-3C |

AF-4C |

AF-5C |

AF-6C |

AF-7C |

AF-8C |

AF-9C |

AF-10C |

AF-11C |

|

Max.feeding width |

mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

|

Max.feeding length |

mm |

50 |

80 |

80 |

130 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

|

Thickness |

mm |

0.5 |

0.8 |

1.2 |

1.5 |

2 |

2 |

2.5 |

2.5 |

3 |

3 |

3 |

|

Pneumatic pressure |

kg/cm2 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

|

Fixed clamp friction |

kg |

10 |

27 |

40 |

55 |

78 |

78 |

90 |

100 |

119 |

119 |

119 |

|

Moving clamp friction |

kg |

30 |

49 |

65.5 |

72.5 |

144.5 |

169 |

200 |

217 |

220 |

245 |

245 |

|

Tension force |

kg |

14 |

16.5 |

19.5 |

25.5 |

41 |

41 |

67 |

74 |

77 |

85 |

85 |

|

Air consumption |

L/min |

26.5 |

38.5 |

47 |

58.6 |

100.5 |

108.5 |

152 |

162.5 |

174.2 |

182.5 |

170.5 |

|

weight |

kg |

8.8 |

9.6 |

12.8 |

19.6 |

38.4 |

52.4 |

80 |

95 |

156 |

178 |

200 |