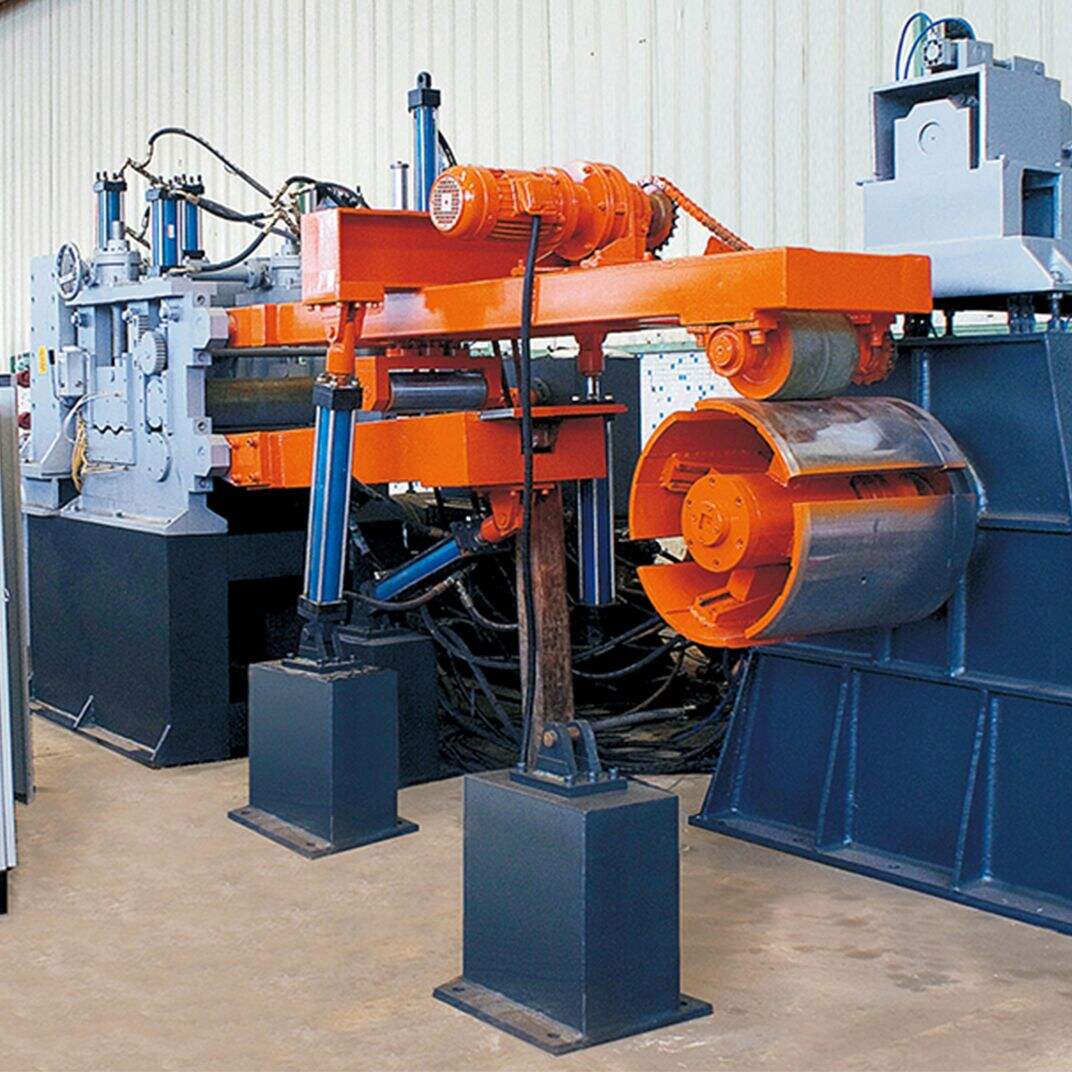

Rapid-Fire Automatic Coil Slitter

- 1. Our slitting line efficiently handles coils of diverse specifications, seamlessly transitioning from uncoiling to slitting and recoiling to produce coils of any required width.

- 2. It is adept at processing a multitude of metal coil types, including cold rolled steel, hot rolled steel, stainless steel, galvanized steel, aluminum, silicon steel, colored steel, or painted steel.

- 3. The application of slitting lines extends across various sectors within the metal plate processing industry, including automotive manufacturing, container production, household goods manufacturing, packaging, and construction materials, among others.

Product Description

I. Outstanding Features

1. Seamlessly integrated with a balanced layout, complete automation, and exceptional efficiency, productivity, precision, and quality, ensuring consistent and smooth operation with user-friendly controls.

2. Employs the cutting-edge Mitsubishi PLC control system, enabling precise global control for optimal performance and management.

3. Optional CPC & EPC systems available to enhance the accuracy of decoiling and recoiling processes, offering increased flexibility to meet specific needs.

4. Engineered with a dependable hydraulic system, robust and rigid structure, and strategically planned site configurations, providing enhanced convenience, practicality, and reliability for operational use.

Ⅱ.Main Components

1. Coil car

2. Uncoiler

3. Pinching device, Straightener and Shearing machine

4. Looper

5. Side guiding

6. Slitting machine

7. Scrap recoiler (both sides)

8. Looper

9. Separator and tension device

10. Recoiler

11. Unloading car for recoiler

12. Hydraulic system

13. Pneumatic system

14. Electrical control system

Ⅲ.Technical process

Coil car → uncoiling → pinching, straightening and coil head cutting → looper → guiding → slitting → side scrap winding → looper → material pre dividing, tension → recoiling → unloading car

Ⅳ.Parameter

| Model | Width(mm) | Thickness (mm) | Coil Weight (T) | Slitting Strips | Slitting speed (m/min) | Floor Area (m) |

| LH-SL-450 | 400 | 0.2-3 | 1-3 | 2-20 | 0-120 | 4×15 |

| LH-SL-650 | 600 | 0.2-3 | 1-5 | 2-20 | 0-120 | 4.5×15 |

| LH-SL-850 | 800 | 0.2-3 | 1-6 | 2-20 | 0-120 | 4.5×16 |

NOTE:The machine can be desighed according to client's special demand, above details for reference only.