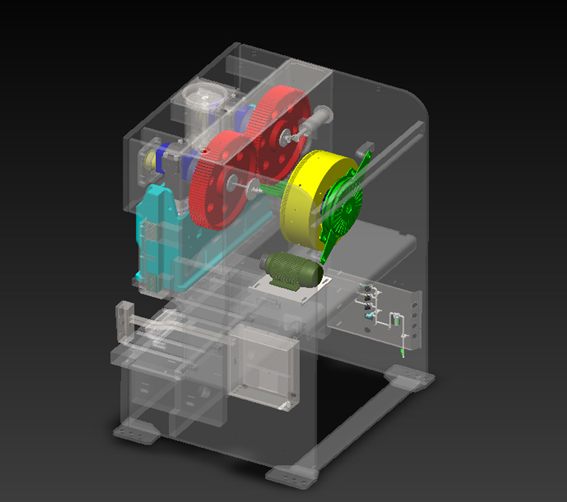

SYC Series open-type double crank precision punch press (110-315T), stamping machine for metal

Product Description

SYC Series Open-Type Double Crank Precision Punch Press (110-315T)

Product Features:

1. The machine body is welded of quality and treated by tension elimination,improve stability and reliability of precision of the machine.

2. In order to guarantree the machine running in stable and smooth, adopts the design of symmtrical two slid boards with balancer.

3. The precision of mold adjusting up to 0.1mm, safety reliable and convenient.

4. Crank, gear. connect bar are oxidized hardening and milled, having super comrehensive mechanical perfor-mance and durable function.

5. Reasonable structural design, is convenient for au-tomatic production and line production.

6. Used reliable high intensity clutch/brake and twin electromagnetic valve, overloading protector can guar-antee safe production all-around.

7. Adopt safety double solenoid valve and hydraulic overload protection device to ensure production and operation safety.

8. The mold bearing large impact loading as well as pressing of eccentric mold.

9. Adopted closed electric loop circuit, have compatible with any automatic equipments.

Standard Unit:

Dry ciutch & brake

Standard operating system

Operating mode selection

Hydraulic overload protector

Frequency conversion

Overrun detector

Portable 2-hand push

Dual solenoid valve

Automatic slide adjust devicet

Digital die height indicator

Automatic lubrication system

Total counter, 6 digits

Preset counter, 6 digits

Maintenance counter, 6 digits

Life counter, 6 digits

Electronic rotary cam switch

Air blowing device

Air source reeptacle

Missfeed detection circuit

Power Receptacle

Optional:

Die cushion

Safety light curtain

Slide knock-out device

Main motor reversing circuit

Foot switch

Safety die block with plug

Dual solenoid valve with Inverter

Missfeed detector

Flywheel brake

Quick die change system

Upper/Loser die clampe

Die lifter、 Die arm

Automatic feed euipment

NC straightener feed (3 in 1)

NC roller feeder

Straightene

| Specification | Unit | SYC-110 | SYC-160 | SYC-200 | SYC-250 | SYC-315 | |||||

| Model | V | H | V | H | V | H | V | H | V | H | |

| Capacity | Ton | 110 | 160 | 200 | 250 | 315 | |||||

| Rate tonnage point | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Stroke | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 300 | 170 |

| Stroker per Minute | s.p.m | 35-65 | 50-100 | 30-55 | 40-85 | 25-45 | 35-70 | 20-35 | 30-60 | 20-35 | 30-50 |

| Die height | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 615 |

| Slide adjustment | mm | 100 | 100 | 120 | 120 | 120 | |||||

| Slide area | mm | 1400x500x70 | 1600x550x70 | 1850x650x95 | 2100x700x95 | 2100x700x95 | |||||

| Bolster area | mm | 1800x650x130 | 2000x760x150 | 2400x840x170 | 2700x900x170 | 2750x900x190 | |||||

| Main motor | kw.p | 11x4 | 15x4 | 18.5x4 | 22x4 | 30x4 | |||||

| Air pressure | kg/cm2 | 6 | |||||||||

| Presses precision | GB/JIS 1 class | ||||||||||

| Presses dimension | mm | 1745x2000x3059 | 1940x2200x3709 | 2235x2620x3849 | 2545x3000x4304 | 2545x3010x4689 | |||||

| Die cushion effective area | mm2 | 350x235x2 | 410x260x2 | 540x350x2 | 640x470x2 | 640x470x2 | |||||