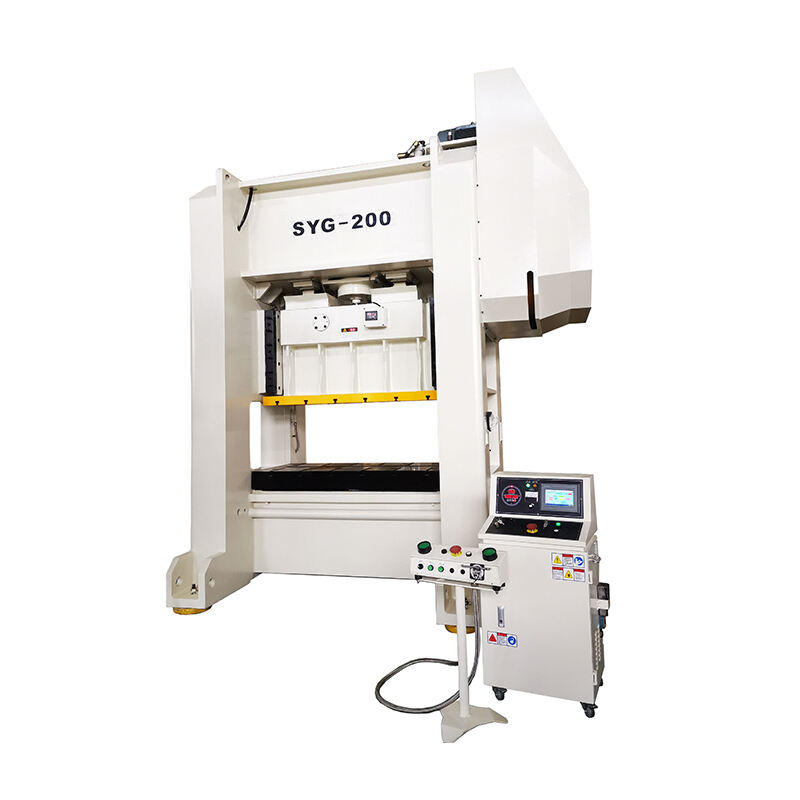

SYG Series Closed-Type Double Crank High-Speed Precision Press (80-300T): Advanced Technology for High-Precision, High-Speed Stamping

Product Description

Product Features

- Motorized shut height adjustment offers convenience, strong self-locking capability, and ease of maintenance.

- Integrating European and American technology with innovative design, the dual guide pillar and four round auxiliary guide pillar slider drive main body provide multi-point guidance. This ensures high precision under ultra-high-speed or eccentric load stamping conditions. Additionally, it features advanced functions such as hydraulic motor-driven die adjustment and servo-driven die adjustment with dynamic pressure ratio setting and correction capabilities.

-

The fuselage selects the high quality steel plate, according to the high precision, the high strength design, after welding the stress removal processing, the deformation is small, therigidity is good.

-

Slide block adopts eight-sided quide rail, stable precision.

-

The combined bearing improves the rigidity and running accuracy of the machine tool, and reduces the total clearance and the heating of the supporting parts.

-

Hydraulic overload protection device, sensitive response, reliable action.

-

Combined pneumatic friction clutch brake, slipper equipped with pneumatic balancer, smooth operation, low noise.

-

PLC electrical control system with sensitive action, reliable performance and good man-machine interface.

-

Automatic timing, fixed point, quantitative thin oil lubrication, lubrication sufficient.

Standard Unit

- Touch screen system

- Hydraulic overload protector

- Automatic slide adjust devicet

- Electric thin oil lubricating device

- Sliding block and die balancing

- Electronic cam

- Main motor reversal device

- Automatic die height indicator

- Secondary drop protection device

- Flywheel brake

- Mistransmission detection device

- Air blowing joint

- Air source receptacle

- Imported oil collecting silencer

- Frequency conversion

- Maintenance tools and toolbox

- Counter

- Operating specification

Optional

- Wet clutchAir die cushion

- Spot safety deviceIncabloc

- Die Room Light

- Dual solenoid valve with

- Oil collecting silencer

- Safety die block with plug

- Flywheel brake

- Tonnage display

- Buzzer

- Emergency door

- Temperature control monitoring device

- Mode-shifting arm

- Automatic peripheral equipment

- Manipulator

- T type operating table

Specification

| Specification | Unit | SYG-125 | SYG-160 | SYG-200 | SYG-300 | SYG-400 | SYG-500 | |||

| Moel | A | A | B | A | B | A | B | A | A | |

| Capacity | Ton | 125 | 160 | 200 | 300 | 400 | 500 | |||

| Rated tonnage point | mm | 3 | 3 | 3 | 3 | 3 | 3 | |||

| Stroke | mm | 70 | 70 | 25 | 80 | 25 | 80 | 25 | 80 | 80 |

| Stroker per Minute | s.p.m | 60-140 | 60-120 | 150-250 | 60-120 | 150-250 | 50-100 | 120-220 | 40-90 | 40-70 |

| Die height | mm | 550 | 580 | 320 | 580 | 400 | 600 | 450 | 600 | 620 |

| Slide adjustment | mm | 170 | 170 | 50 | 170 | 50 | 170 | 50 | 170 | 170 |

| Slide Area | mm | 1600x700 | 1800x800 | 1750x460 | 1800x800 | 1750x520 | 2000x900 | 1900x560 | 2200x1000 | 2300x1000 |

| Bolster Area | mm | 1700x800 | 1900x900 | 1750x600 | 1900x900 | 1880x700 | 2100x1000 | 2100x800 | 2300x1100 | 2400x1100 |

| Bolster thickness | mm | 160 | 180 | 180 | 180 | 190 | 180 | 200 | 200 | 200 |

| Side opening | mm | 600x500 | 700x500 | 840x380 | 700x500 | 840x400 | 800x550 | 840x500 | 800x550 | 800x550 |

| Main motor | kw.p | 18.5x4 | 22x4 | 18.5x4 | 30x4 | 22x4 | 45x4 | 45x4 | 55x4 | 75x4 |

| Air pressure | kg/cm2 | 6 | ||||||||