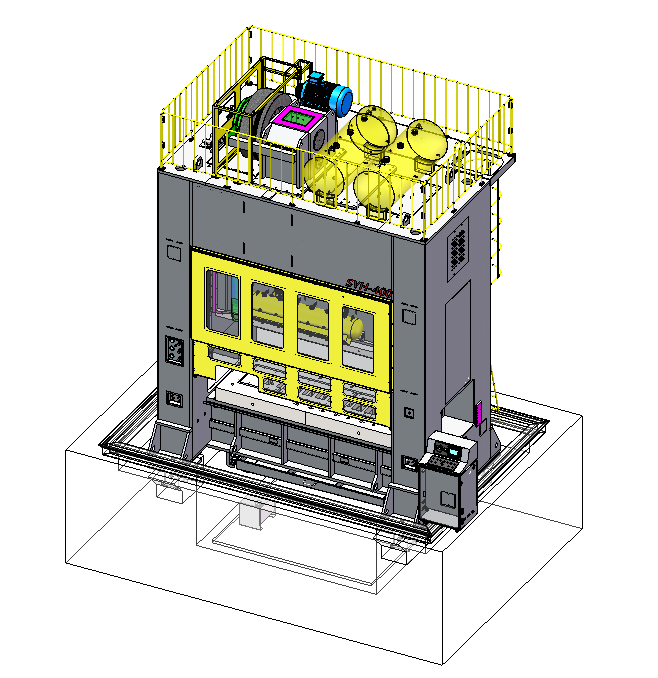

SYH Series Closed-Type Dual Point Precision Press (200-800T): Advanced Design with Steel Plate Body, Imported Pneumatic Friction Clutch, and High-Performance Features

Product Description

Product Features

- Critical and large parts are optimized using finite element analysis.

- The fuselage and slider are constructed from steel plates and undergo aging.

- The fuselage is segmented into cross beams, columns, base, and closed using four tensioning screws, ensuring rigidity and minimal deformation.

- Utilizes an eccentric axis arranged in left-right directions with a large center distance between two links, providing strong resistance to offset loads suitable for continuous operation.

- The main motor features a frequency conversion speed regulation system to expand the machine's operational capabilities.

- Features imported or self-made dry air friction clutches.

- Includes imported hydraulic overload protection with rapid component response and quick reset.

- Motorized adjustment of the shut height for ease of use, strong self-locking capability, and easy maintenance.

- Equipped with PLC control and a dual-circuit power electrical system.

Standard Unit

- Dry integral or split clutch

- Hydraulic overoad protector

- Automatic slide adjust devicet

- Electric thin oil lubricating device

- Sliding block and die balancing

- Electronic cam

- Main motor reversal device

- Automatic die height indicator

- Secondary drop protection device

- Programmable Logic Controller

- Moved operation table

- Air blowing joint

- Air source receptacle

- T type operating table

- Foundation bolts

- Maintenance tools and toolbox

- Operating specification

Optional

- Wet clutch

- Air die cushionMoving bolster

- Touch screen system

- Frequency converters

- The slider a konckout device

- Safety light curtainFlywheel brake

- Die room brake

- Dual solenoid valve with

- Oil collecting silencer

- Safety die block with plug

- Flywheel brake

- Tonnage display

- Buzzer

- Emergency door

- Temperafure control

- Mode-shifting arm

- Automatic peripheral equipment

- Manipulator

Specification

| Specification | Unit | SYH-200 | SYH-260 | SYH-300 | SYH-350 | SYH-400 | SYH-500 | SYH-600 | SYH-800 | SYH-1000 | SYH-1200 | ||||||||||

| Model | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |||

| Capacity | Ton | 200 | 260 | 300 | 350 | 400 | 500 | 600 | 800 | 1000 | 1200 | ||||||||||

| Rate tonnage point | mm | 9 | 7 | 9 | 7 | 9 | 7 | 13 | 7 | 9 | 7 | 12 | 8 | 12 | 8 | 12 | 8 | 13 | 9 | 13 | |

| Stroke | mm | 250 | 150 | 300 | 200 | 300 | 250 | 350 | 250 | 400 | 300 | 400 | 250 | 350 | 250 | 350 | 250 | 400 | 300 | 400 | |

| Stroker per Minute | s.p.m | 20-50 | 50-90 | 15-40 | 30-70 | 15-40 | 30-60 | 15-40 | 30-60 | 15-25 | 20-40 | 15-25 | 15-35 | 15-25 | 20-35 | 15-25 | 20-35 | 10-20 | 15-25 | 10-20 | |

| Die height | mm | 500 | 600 | 600 | 600 | 700 | 650 | 840 | 600 | 900 | 700 | 1000 | 800 | 1000 | 900 | 1200 | |||||

| Slide adjustment | mm | 150 | 150 | 150 | 150 | 150 | 250 | 250 | 250 | 250 | 300 | ||||||||||

| A Slide area | mm | 1650×1100 | 1850×1150 | 2150×1200 | 2550×1200 | 2500×1300 | 3000×1400 | 3600×1400 | 4500×1600 | 4500×1600 | 5000×1800 | ||||||||||

| B Slide area | 1850×1100 | 2150×1150 | 2500×1300 | 2800×1300 | 3400×1300 | 3600×1400 | 4600×1500 | 5000×1600 | 5000×1600 | ||||||||||||

| A Bolster area | mm | 1800×1200 | 2000×1250 | 2150×1300 | 2550×1300 | 2500×1400 | 3000×1500 | 3600×1500 | 4500×1600 | 4500×1600 | 5000×1800 | ||||||||||

| B Bolster area | 2000×1200 | 2300×1250 | 2500×1400 | 2800×1400 | 3400×1400 | 3600×1500 | 4600×1500 | 5000×1600 | 5000×1600 | ||||||||||||

| Thickness | mm | 150 | 170 | 180 | 190 | 200 | 220 | 250 | 280 | 300 | 300 | ||||||||||

| Side opening | mm | 550 | 600 | 650 | 650 | 800 | 900 | 1000 | 1000 | 1000 | 1200 | ||||||||||

| Main motor | Kw.P | 22×4 | 30×4 | 37×4 | 37×4 | 45×4 | 55×4 | 75×4 | 90×4 | 110×4 | 132×4 | ||||||||||

| Frame structure | integrated | integrated /split type | split type | ||||||||||||||||||

| side adjust device | It can be configured with forward, side and T-type moving table | ||||||||||||||||||||

| Air pressure | kg/cm2 | 6 | |||||||||||||||||||

| Presses precision | GB/JIS 1class | ||||||||||||||||||||