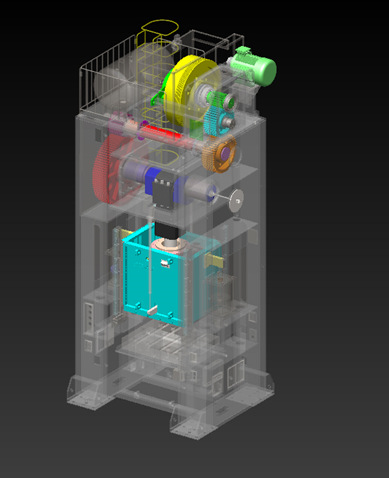

SYJ Series Closed-Type Single Point Precision Punch Press (100-600T): High-Precision, High-Strength Design for Automated High-Load Stamping

Product Description

Product Features

1. The machine body is made of high-quality steel plates, designed for high precision and high strength. Post-weld stress relief treatment ensures stable accuracy and reliable performance.

2. The die adjustment precision is up to 0.1mm, offering safety, convenience, and reliability.

3. The machine's structure is reasonably designed and fully equipped, facilitating the implementation of automated and assembly line production.

4. It features a high-strength combination clutch/brake system, ensuring smooth engagement and reliable safety.

5. Constructed with premium alloy steel and optimized single crankshaft design, this press is ideally suited for high-load stamping of large-size dies.

6. The enclosed electrical circuit design is powerful and versatile, compatible with any automation equipment.

Standard Unit

- Hydraulic overload protector

- Automatic slide adjust devicet

- Automatic die height indicator

- Sliding block and die balancing

- Air source receptacle

- Overrun detector

- Main motor reverse device

- Frequency conversion

- Electronic cam

- Crankshaft angle indicator

- Air blowing joint

- Maintenance tools and toolbox

- Flywheel brake

- Mistransmission detection device

- Imported oil collecting silencer

- Touch screen control device

- Automatic lubrication system

Optional

- Die cushion

- Quick die change system

- Slide knock-out device

- Safety light curtain

- Mould lighting device

- Automatic feed equipment

- Prejudge, precut counter

- Foot switch

Specification

| Specification | Unit | SYJ-100 | SYJ-150 | SYJ-200 | SYJ-260 | SYJ-300 | SYJ-400 | SYJ-500 | SYJ-600 | ||||||||

| Model | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |

| Capacity | Ton | 100 | 150 | 200 | 260 | 300 | 400 | 500 | 600 | ||||||||

| Rate tonnage point | mm | 6 | 3 | 6.5 | 4 | 7 | 4 | 7 | 4 | 9 | 7 | 10 | 7 | 13 | 7 | 13 | 7 |

| Stroke | mm | 180 | 40 | 200 | 40 | 250 | 40 | 250 | 40 | 300 | 250 | 300 | 200 | 350 | 250 | 350 | 250 |

| Stroker per Minute | s.p.m | 20-45 | 80-180 | 20-40 | 80-150 | 20-40 | 60-130 | 20-40 | 50-110 | 20-35 | 20-35 | 20-30 | 25-35 | 15-25 | 20-30 | 10-25 | 20-30 |

| Die height | mm | 450 | 290 | 500 | 310 | 550 | 350 | 550 | 380 | 650 | 550 | 550 | 600 | 600 | 650 | 650 | 700 |

| Slide adjustment | mm | 100 | 120 | 150 | 150 | 150 | 150 | 150 | 150 | ||||||||

| Slide area | mm | 700x600 | 700x700 | 800x800 | 900x800 | 1000x900 | 1100x1050 | 1250x1100 | 1400x1200 | ||||||||

| Bolster area | mm | 700x700 | 800x700 | 900x900 | 900x900 | 1100x1000 | 1300x1100 | 1450x1100 | 1600x1200 | ||||||||

| Side opening | mm | 400x400 | 400x400 | 400x400 | 400x400 | 400x500 | 650x550 | 650x600 | 700x650 | ||||||||

| Main motor | kw.p | 15x4 | 22x4 | 22x4 | 30x4 | 30x4 | 45x4 | 55x4 | 75x4 | ||||||||

| Air pressure | kg/cm2 | 6 | |||||||||||||||

| Presses precision | GB/JIS 1class | ||||||||||||||||