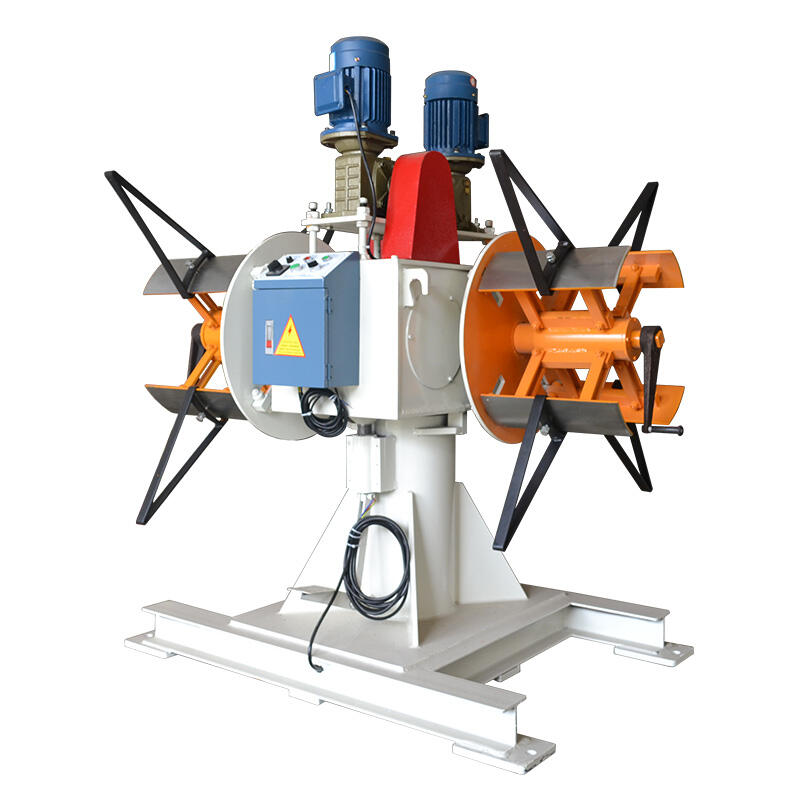

I-DBMT i-Double-Head Uncoiler ngee-Speed Control Box zimetal sheets , idecoiler esifanelekayo namawidhsi we-material ezi-200mm - 400mm

Yabelana

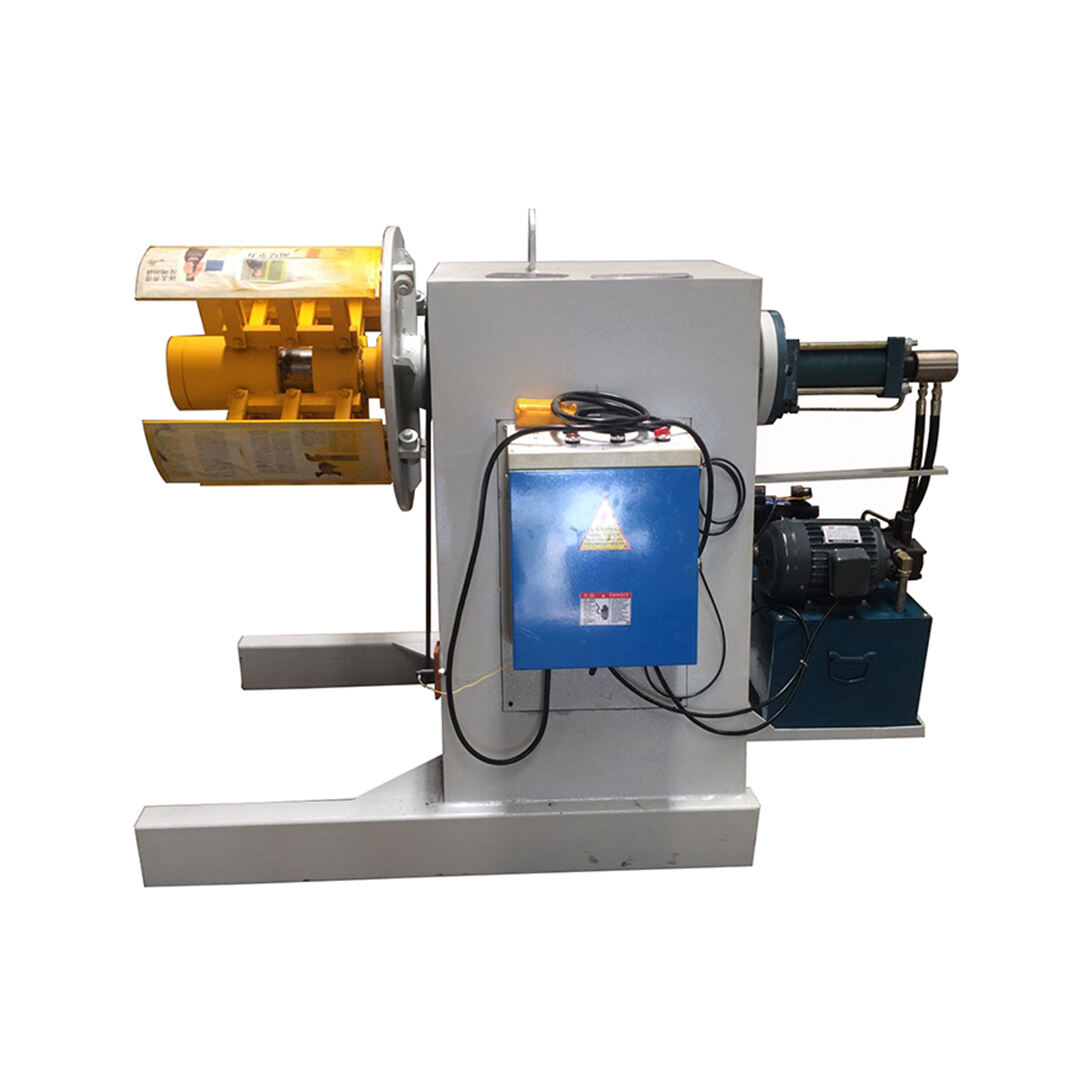

Ukuphucuka kweziyekisela ngokusebenzisa i-Hydraulic (kwi-3 ton above uncoiler)

I-Arm yokugcina kweziyekisela ngokusebenzisa i-Pneumatic (kwi-1.6mm ngaphandle kokuthini thickness)

Umbiko wesishiyagalombili usetyenziswa ngokusebenzisa ifeeti

Izixhobo

1. Ukuvumelana nokuhlola imithombo, ukuyifunyanwa kwezinto zokusebenza

2. Ungayisebenza ngokuhlanganisayo nesirayitha.

3.Unokwenzela ukuba zikhangeze kwi-motor ngeyibhizinisi lokusebenza kunye ne-motor.

4.Ngenxa yomsebenzi okanye nohlangothi elithathu.

5.Le msebenzi iyi-ready ye-high speed punching, njengalokuhlola, rotor kunye ne-ET sheet, netheku leyo.

Inqwaba Yokuqinisekisa

Umgibe Wokuqala Emyeza Emibini Omkhulu

Ustrakichi Womthwalo:

1. Umhlanga womgibe

2. Amatayela

3. Umphendulo

4. Isikrhi somhlawula

5. Isihlobo somhlawula

6. Umhlanga wamanani

Izixhobo :

1. Ukuphatha isikhathi sokubuyisela imfundo nokuthuthukisa umthwalo.

2. Inakwazi ukusetyenziswa ngesiqephu esebenzisa ngokuphathelana nokumakhiwa omncedisiweyo.

3. Inakwazi ukubuyisela ngumotshani kunye nokontrola yeelektroniki ukuze zikhuluze kwiqephu eluhlaza amandla.

4. Iyiphandleni yokukhulula: ukukhulula ngehand crank yenkabi kunye nokukhulula ngehydraulic.

5. Ngenxa yamathebha apho, izimodifikasi zingazangelelwa ukuthi zityatyiseleyo kwindawo ye-left kunye ne-right.

6. Leli qephu liyiya kubalulekile kuhluke amandla, njengomthwalo, irotors kunye ne ET sheets.

Umsindo Wobunzima

1. Leli qephu lingenisisi, indawo yesipheni sokugcina kunye nokunquma okufundekayo. Indawo yesipheni sokugcina sifuna ukuba inguqulelo, isisebenziso sesikhwama esincane, usizo osicacileyo, umphathi womndeni ohlindeke, kunye nokusetyenziswa okungcono.

2. Ngenxa yokuquka kwezinye ezimbini zindawo, inakwazi ukufaka imali ngexesha lokusebenza, ukulinganisa isikhatsi somoya sokuphatha imali, ukuphucula umsebenzi wendawo kunye nokuphucula ukuziphatha imali.

3. Isishova sikhethekile kanye nokungakhethekanga amandla kunye nokusetshenziswa ngesiqephu esebenzisa ngokuphathelana nokumakhiwa omncedisiweyo kunye nokumakhiwa omkhulu.

Umkhopho wezolo kunye nolwandle

1. Iimeyile ziingxenye le-A3, zicala ngokubheka emuva kokucutshwayo, phakathi kokufundiswa kumeyile chamfer kunye nokufundiswa kumeyile chamfer, phakathi kokufundiswa kumeyile chamfer kunye nokufundiswa kumeyile chamfer.

2. Zonke iindlela zicalwa ngamandla weqhutyeni wesha, ukusure ukuba amandla weqhubulo angaphakathi kwezi zinto, ukuze aliphumeleye ukusetyenziswa kwesikhashana kunye nokuziphatha ukukhupha.

3. Indawo yesha yescrew kunye nokusha escrew ikhona okanye lokungaphezulu lokuhlola ukubuyiselwa komoya wesha, ukuze akukho isikhatsi esikhoyo esifanelekayo ukubuyiselwa.

Isiqephu

1. Ukusebenzisa i-80-type worm gear vertical reducer, ukuhlanganisa nesi-gear speed converter, ukubonisa isokudla sesithathu sethe siphambili kwi-speed esidingiweyo nokufumana umehani wenqanawe ngokushaya.

2. Ukusebenzisa imotori yesikhatsi, yenye uphazamo kunye nomoya ongenzi kakhulu. Isiqondisi sifuneka sihlale pure copper coils, inyezi elizityalo lekuphi lomcoils okanye. Inikezwa ne-ball bearings ezimbini, ezinceda uphazamo oluncinci kunye nokugcwalelo.

I-Electric control box

1. Ukusebenzisa amareleyi we-silver alloy, amacilishane we-copper, kunye ne-safety bases ezintshontsho zokuthola, uzogcina ukukhula kakhulu.

2. Inqanawa yenqanawe yokulungisa okusetyenziswa nokuphumelela iindlela yezilondolozi ezichasene, amaphethelo amaseleya, amandruma angaphezulu, akubhekisele ngokushesha kwezinye izilondolozi.

3. Amaswitch ayisebenza amaphandle kwe-sliding contacts amaphandle kwe-self-cleaning function. Amaphandle kwe-normally open kunye ne-normally closed contacts ayisebenzisa umthetho omphumeleleyo, ungene ubuchwephesha, nge-anti-rotation positioning kunye ne-anti-loosening mounting pads.

4. Ukusebenzisa amandla aphakathi amabhileyo, ezincedisi kakhulu nokusebenza, ngenxa yamathebhu omndeni. Iindlela zokukhombisa zisebenzisana namaphuzu ephakathi, eziziphindaphindi ukusetyenziswa kunye nokuthola amalayenti ekubeni, ngokwesikhatsi esidingayo usuku lwe 1 million cycles.

Iphakathi laphezulu

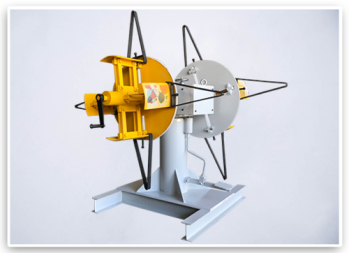

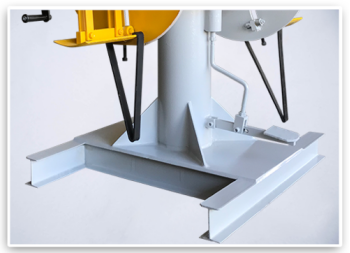

1. Iframe iyishintsho elizama ngokulandelwa, usebenzisa imakhi eziqondisiwe ezimbini ukuze ulandelwe. Ukulandelwa kufika ngekupheleni kwamathathu omphakathi, phakathi ukulandelwa kwezinhlobo zomphakathi ezincinci. Amaphethelo amancinci alandelwa namuhla, phakathi ukulandelwa kwezinhlobo ezibonakaleyo, ukusureka ukubanjwa kunye nokuhlola kwalendawo.

2. Zonke iimateri ali yefreime zicalwa ngokulayithi noma plasma, ukuqonda ukuba kungenzima lokungaphezulu.

3. Zonke iindlela zicalwa ngamashini amacNC kunye neentechnology yenombolo, ukusure ukuba amandla weqhutyeni angaphakathi kwezi zinto.

4. Is trakichi sasendaweni sihle, futhi umsebenzi wokuhlanganisa kunye nokugcina izinto zeqhutyeni zinakwaziwa yonxibelela olunye lwezintekhnikhi, ukuze liyisetyenziso kunye nokuphathelwa kakhulu, ukuhambisana nokubhala imali yokuvuselela.

| Usimo | Umlando wezinto (mm) | I.Dia yeCoil (mm) | O.Dia yeCoil (mm) | Ubuncinci beCoil (kg) |

| DBMT-200 | 200 | 450-530 | 1200 | 500 |

| DBMT-300 | 300 | 450-530 | 1200 | 800 |

| DBMT-400 | 400 | 450-530 | 1200 | 1000 |

| DBMT-500 | 500 | 450-530 | 1200 | 1500 |

Khetho:

Ukuphucuka kweziyekisela ngokusebenzisa i-Hydraulic (kwi-3 ton above uncoiler)

Iphendule yomgca wokugcina amabhaliswano ngokuphelele (ngexesha lapho ubunzima kwi-1.6mm ngaphandle)

Amadrayivh sa ispeed esiyaziwe nge-AC

Umgqibelelo wosishwa wesishayi wawo (ngumotara omkhulu we-hydraulic)

Isikhangiso somgci

Fanelo: Ukufakelwa kwesinye isimo sokubhulisa siyazi ukuba asetyenziswa ukuyifumanisa izidingo zonke ezihlukeneyo.