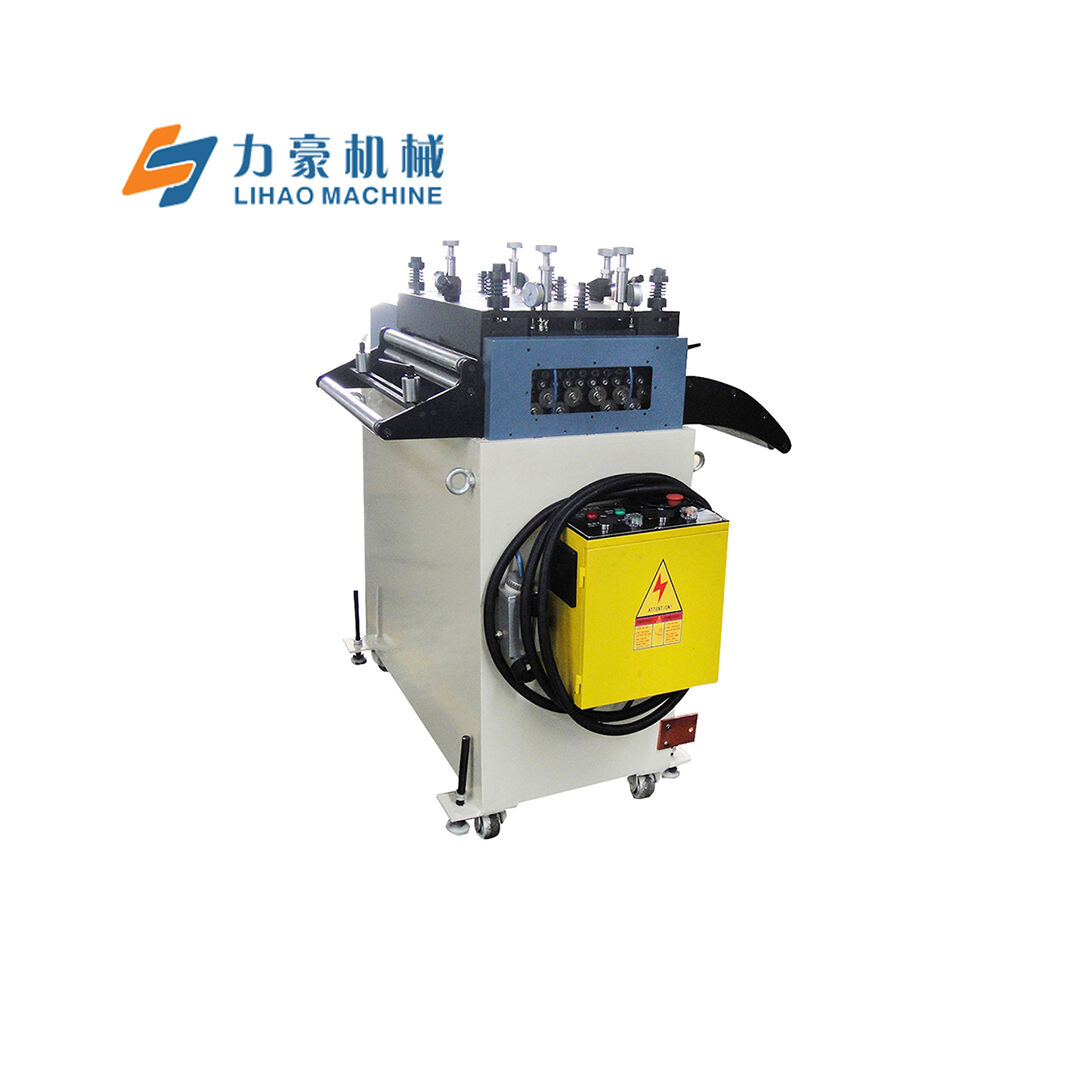

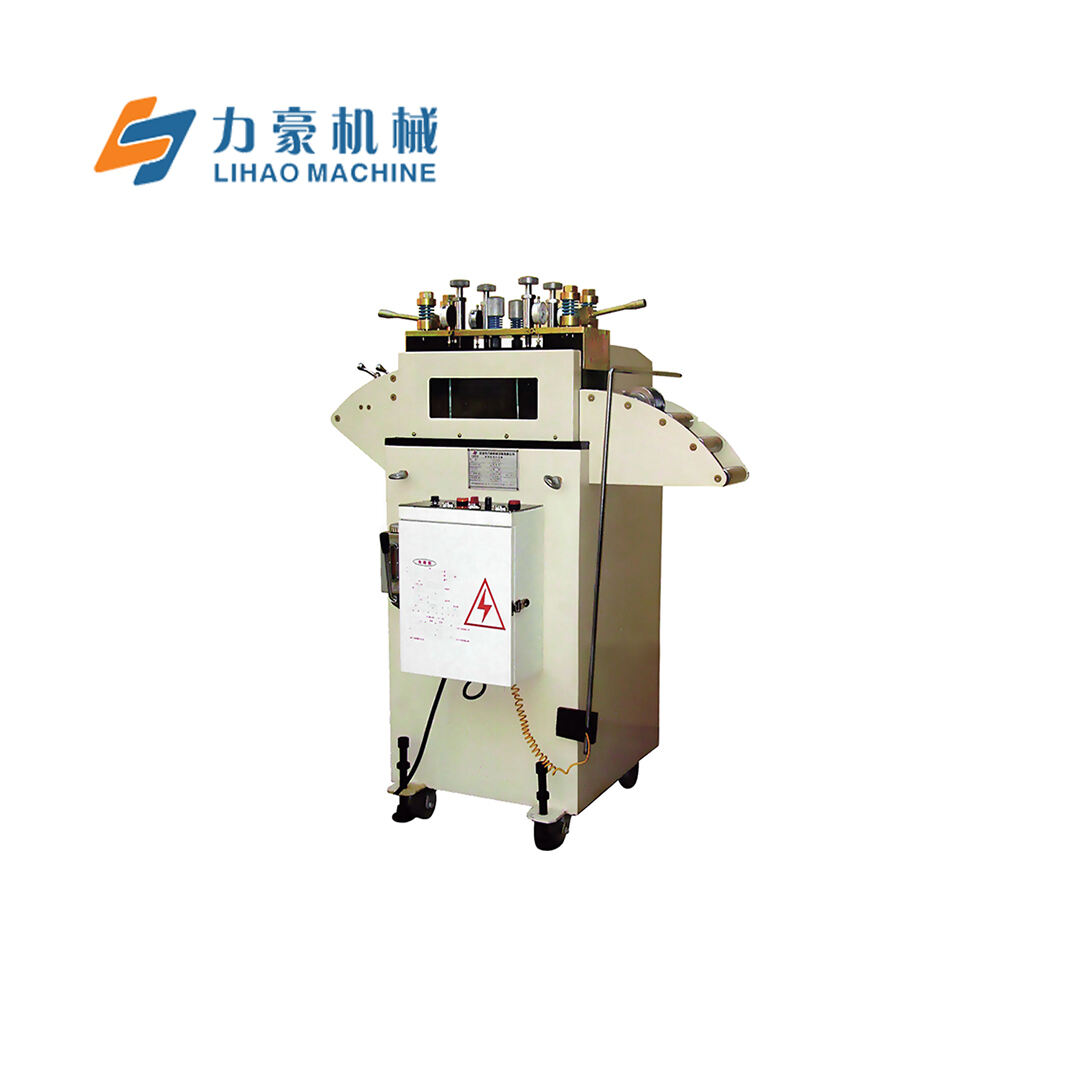

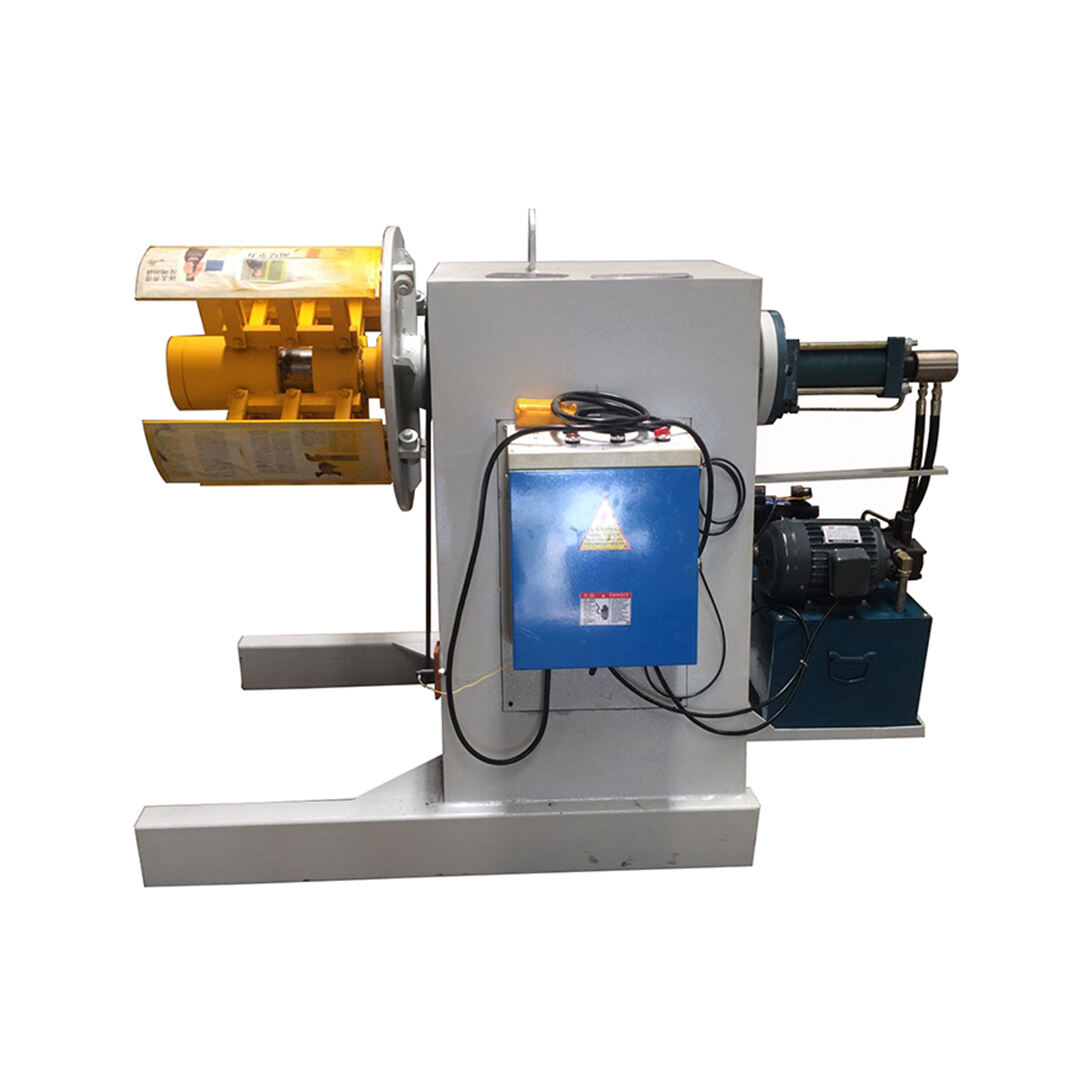

Imakhi ndawo yesithathu seSPS: Ukubuyisela kwezindlela zokungena ngokupheleleyo kumetal esincinci, isimo sokubuyiselwa sokuqala sesi-0.2mm - 1.5mm

Yabelana

Ukusetshenziswa kwesiqhina esisodwa lokusebenza ngokuvamile

Yityipha ngokushesha nokugcina ngenqanawe yokusetyenziswa ngokuzenzekelayo

Unokwenywa ngenqanawe

Inqwaba Yokuqinisekisa

Ukuphawuliwa:

1. Iindlela zezilondolozi leziyiziphi ziyizamekile nezinkxaso zethu zikhishwe ukuba zibuyisele amasheet amanqaku elincinci. Kwikazi ukuba ngaphandle kokubuyiselwa nokuhlola lokuxhasa, ayikho inqanawa yokugcina okuhle. Ngakho ke, uphawu wemakhi webucabuli baphinda ubungena kwindawo yokusebenza.

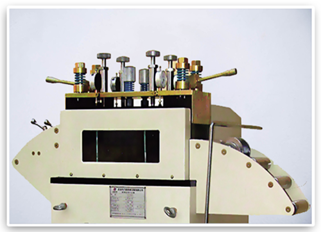

2. Amakhi amabili amalindelene nase correction auxiliary rollers kwiMakhi yokuqala yakhiwe ngamathuba ahlala SUJ2, akhiwe ngokushintsha uHRC60°, akhiwe ngokushayela ngokufaka ihard chromium ukuba zikhohlwe amahambo amandla amaxhego nokuba zingcinane ngokubanzi kumazinye imigca.

3. Ukusetha kwezinto lomthwalo lwakhiwa ngokusebenzisa isisthembe esibonakale sine empahla lokulandela ukubuyiselwa, inqanawa yenani lelula ngenqaku lenqanawe, ucingiswa ukuphinda ukufumana amapoyinti akusethwe.

4. Lomthwalo lumsebenzisa uphawu olunxantyo olunye weziphi zempahla lokulandela kunye nokulandela kuzo zintathu zikhafilelo ezikhoyo, esibonakale yezinto eziyiziphi zinayo izicatshululo elungileyo.

5. Ngokushesha kwezinye iindlela zokulandela, ukudibanisa amaroller okulandelayo ayiqhamuka ngokuthiwe ukukhombisa umoya wemali wesigqibo.

6. Umthwalo omncane ungasebenzise amabheki amahlukile kunye nokuhlelwa kwesistimu sokulubula ukuvulwa kokuthiwe ukuya kwiqhosha lakho.

7. Ngenkathi yonke inqanawe yokubuyekeza kweS series imthwalo eluhlukile yokubuyisela, iyithumelela amaqhawu angaphandle ahlala ukuba akusetyenziswa ngokubuyiselwa noma ukubuyiswa ngaphandle komthwalo, ukuze libuyeleyo kwalendlela yokugcina kwezinto.

8. Amamaroller angaphansi kunye namagunya engaphakathi azifunyenwe, uzimelela ukusindiswa kwezinaroller kunye nokucinga ukubuyiswa ngamava.

9. Umehluko wesithathu wesethulo uqondisa ngokubenzekelayo okugcineni olwandle lwesikhombisi ngendawo yokudibanisa, ukucabangela uphucumayo lwezinye zezikhefu ezifana nesethulo lesikhombisi esinye kunye nokuthola izicatshulwa zokungena kwisekhombisi.

10. Ngokushintsha kwezilimi, ububanzi bunye kunye nobukhothi, akukho inani elizweni lokuvavanywa. Ngakho ke, kufuneka usetyenziswa siphinde isebenza ukususa isiqephu esincane sisisekelwe ngaphambi kokusebenza ngokuphihlwe kwiqhutywa lokuncedwa.

11. Ukusetyenziswa okungenziwayo okungapheleleyo kwesikhombisi sokubuyiselwa.

Ukuthi kuyini:

·Indawo yokuvavanya

1. Isihloko sesikhefumfula sithumele idilesi lekugcineni, ngenxa yalokuba kunye ne-19 amacorha amaphambili, amashumi asine ngalolunye kunye namashumi asihlanu ngasemva.

2. Ukusetshenziswa kweziningi ezine empathe, kufuneka kulandelwe ngokubanzi ukubuyiselwa kwezinto eziphambiliyo. Ukungena kunye nokuhamba kusetshenziswa ngamaningi amapathe amandla amandla kwezinye zezityalo ezindala, uzokususa ukungaba kwezilimi kunye nokubhedelela.

3. I-roller ezikhethiwe ziyindlela elingezwayo ezinamandla amagalayizid, ibhizo lokugcina kanye nokulamba akuyishesha. Izinyathelo eziqondisiwe zisetshenziswa ukubuka nokuhlola ngokushesha.

4. Zihlosi zemanzini ezimbili zisetshenziswa, zithathelwa ngephrothesi yobuso, zinamandla okuthekwangqa kunye nomandla wesikhephe esiqophqwaneleko.

5. Zicala zisetshenziswa ngasibini somphakathi wokuqasha ukuze lisebenze lokuhlola, zidinga amagwa lekuphiwa ukubona ngokuqinile.

·I-rolla leStraightening

1. I-roller lezityenziswa ziyamandla omgalayizid, zithathelwa ngephrothesi yobuso elincinci nakwesicwangciso sesifazane. Ukumthetho kwobuso kunene ayishayiyo ngaphandle kwe-HRC58, ukusureka umandla womgalayizi.

2. U-GCr15 uye steel olwandle olusetyenzisiweyo usebenziswa, uluhlola phakathi kwe-preheating treatment (spheroidizing annealing), phesheya kwencane lokugcina, ukukhombisa, mid-frequency treatment, ukugcina ngokushaya esiqephu sika-cold stabilization, ukugcina ngokupinini, kunye nelektroplating ngemvume. Isimo sesikhatsi sokugqibela leyi maximizes isicwangciso, concentricity, smoothness, kunye nolungu, futhi ifaka umoya wesixhobo. ukulindiswa amaphethelo.

·I-gear yesithuthelo

Umkhuthazo wokuphatha amageari iyangxenywa ngamandla ezi: uphawula kwe-gear blank - uphawula kwe-tooth surface - heat treatment - ukugcina kwe-tooth surface. Ukubuyiselwa kusetyenziswa kukusebenzisana nokuba kwenye into engenakwaziyo yokuphawula; ngokuqinisekisa amageari, ukuhlola kwesicatshulwa sokunyusa, phakathi kokunyusa kunye nokunciphisa, ukutheya nokukhipha, kunye nokuphawula kwe-gear hobbing ukufinyelela umkhondo we-gear. Ngemva kwalokho, ukungena kwe-heat treatment ukuvumela iziphiwo zokugcina. Ngokwesiqhelo sokucacisela, ukuphawula okujongene kusetyenziswa lapho lokuhlola, ukubuyiselwa kwe-standarde kunye nokuphawuza kwe-gear. Ngokusebenzisa amakhuthazo amaningi, igear yakho iyiphindaphindi 6, iyithinta umthengiso womphulo, umthengiso omkhulu kunye nokuzihlaba ekunene.

·Isixhobo

1. Ukusebenzisa isilondolozi semodeli 80 worm gear esincinci, usebenzisa umkhuthazo wokuphawula amageari ukuphuma imvume yomoto kuvela ngendlela elizodingiweyo, futhi ukufinyelela umehani wesinqumo.

2. Ukusebenzisa imoto eviki ehlukileyo elishona ngokuthi akhihli kanye nokugunywa. Isixenxe esisetyenziswa sifakile amacu wekhoba olungempumlo, ukuze lisekhe umoya wokugcwalisa esibini nezi zokudala. Amabebhu azenyelwe kusasa ngezantsi kunye negapha, lokhu kufuneka kuhlanganise ukusuka nokuhlaba.

·Ibox yomdumelelo ovela ngemoto

1. Siyenza uphawu lwesilwane lesikhombisa ngekhoba lemkhandlu wesilwane, ifakwe kwiqela lenqanawe yokuhlola ukubanjwa, ukusukelela ukuba liyindawo elidingayo.

2. Ukusebenzisa iqude lemfazwe elihlobene ngesicelo sokulandelela esetshenziswa ngekhomba lemkhandlu wesilwane, ngeamandla amaningi lodwa lokulandelela ukungenza izindlela eziningi zokulandela.

3. Izityhili zisetshenziswa ngekhonjane ekhulu elihlobene nesicelo sokushintsha. Ikhonjane elilandelayo kunye nelilandelayo elingasetyenziswa zisetshenziswa ngesicelo sesiqembu esisethweni, ifakwe nge-anti-rotation positioning kunye nesipadi somthengiselo.

4. Siyaziya amandla esetinteni ezikhundleni zokupindziswa ngekona elungileyo, amakhetho amahhovu, amakhetho amaphakathi, kunye notheleliso olunemvume omodulari. Izindlu zokukhombisa zizama imibono engamagqabi, zinakuyenza amalayenti ebo, kunye nokulandelana okungenani kwezi sicolo zokuqala.

·Isihloko semitha, inhlangano yesiNto

1. Ukusebenzisa inhlangothi yebhola leyiManuali yokuthumela uMphoyi ngokushesha kunye nokugqiba. Iziphongezi zomlayo ezilungisiwe ziyingxenye ukusuka komlayo, kunye neziphongezi ezilungisiwe zeSpring zingasetyenziswa nokubekelwa.

2. Ukusebenzisa i-steel dial indicator nge-dial face engenziwe ngokuphumulekile, iglass engavuli ifezile kunye ne-copper inset phakathi. Lwendawo lunakho icore yeCopper ukuthatha isidingo kunye nokukhombisa ngokupinumo.

Izimvumulo:

| Imodeli | SPS-150 | SPS-200 | SPS-300 | SPS-400 |

| Ububanzi bewondlela (mm) | 150 | 200 | 300 | 400 |

| Ububanzi (mm) | 0.2-1.5 | 0.2-1.5 | 0.2-1.3 | 0.2-1.2 |

| Isidlelo (m/min) | 16 | 16 | 16 | 16 |

| Imoto (HP) | 1HP×4P | 2HP×4P | 2HP×4P | 3HP×4P |

| Iroller yesikhombisi (mm) | Φ24 | Φ24 | Φ24 | Φ24 |

| Isiqephu esishaya somntu (Amacandi) | 9⁄10(Emfutshane/Ngenxelo) | 9⁄10(Emfutshane/Ngenxelo) | 9⁄10(Emfutshane/Ngenxelo) | 9⁄10(Emfutshane/Ngenxelo) |

| Isiqephu sokuqinisekisa (mm) | Φ30 | Φ30 | Φ30 | Φ30 |

| Inani leSisiphephe Sokuqinisekisa (Amacandi) | 10⁄11(Emfutshane/Ngenxelo) | 10⁄11(Emfutshane/Ngenxelo) | 10⁄11(Emfutshane/Ngenxelo) | 10⁄11(Emfutshane/Ngenxelo) |

| Ubukhulu (m) | 1.1×0.8×1.4 | 1.1×1.3×1.4 | 1.1×1.4×1.4 | 1.1×1.5×1.4 |