Precision stamping processes play a crucial role in the 3C (Computer, Communication, and Consumer Electronics) industry, encompassing the manufacturing of smartphones, tablets, and other communication devices. Therefore, advanced technologies and specialized equipment are essential to meet the industry's high demands and complexities:

High Precision Requirements:

The 3C industry demands high precision for components. A key aspect of precision stamping is the utilization of the Decoiler-Straightener-Feeder (DSF) series with a servo system, ensuring compliance with stringent product design specifications.

Complex Geometric Shapes:

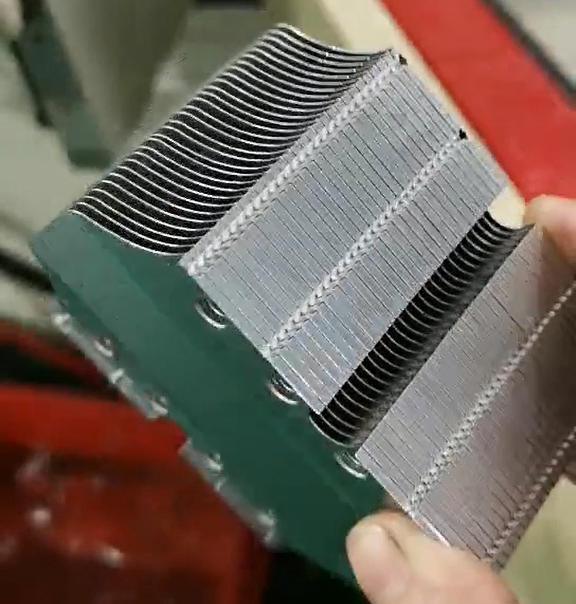

3C products often feature intricate geometric shapes, including small holes, bends, and irregular structures. Precision stamping processes exhibit flexibility in addressing these complexities. The servo feeder series, consisting of a material loading trolley, material rack, and straightener, plays a pivotal role. The material loading trolley facilitates reliable movement, lifting, and placement of various coil specifications on the material rack, easing subsequent operations. The material rack supports coil placement during feeding, sensing the feeding status in real-time, and autonomously stopping or adjusting the feeding speed, achieving fully automated feeding. The straightener employs two rows of finely adjustable, high-precision, and high-hardness rollers to compress and flatten the coil, eliminating internal stresses, altering the material's external form, and ensuring material flatness, meeting the material performance requirements in punch press operations.

The scientifically intelligent electrical control system ensures seamless coordination between these components, enabling reliable and efficient automated operations for material loading, uncoiling, and feeding.

Processing Thin Sheet Materials:

Given the prevalent use of lightweight and thin sheet materials in 3C products, precision stamping processes excel in handling these materials without deformation or damage.

High-Speed Production Demands:

Precision stamping processes' high-speed production capabilities effectively meet the large-scale production needs of the 3C industry, significantly enhancing overall production efficiency.

Compact Layouts and High Integration:

Aligned with the trend toward miniaturization in 3C products, precision stamping processes enable compact layouts, facilitating highly integrated production lines within relatively small spaces.

Automation Applications:

Precision stamping processes often incorporate automation technologies, utilizing intelligent control systems and robotic technologies to enhance production efficiency while reducing the occurrence of human errors.

These process characteristics position precision stamping as a key manufacturing technology to meet the 3C industry's requirements for high-quality and high-efficiency production.