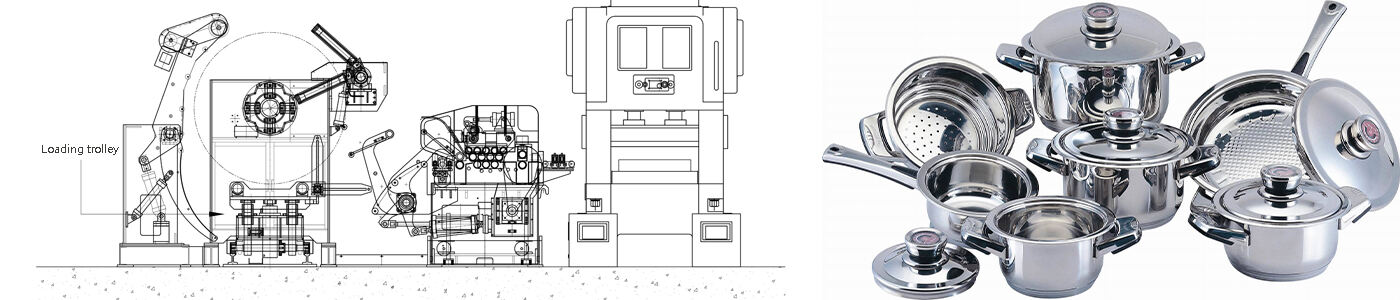

In the realm of household appliances manufacturing, the integration of a complete production line comprising a press machine, servo feeder, straightener, and decoiler plays a pivotal role in enhancing efficiency, precision, and overall production quality.

Equipment Overview:

Press Machine:

The press machine serves as the primary workhorse in the production line, executing the intricate stamping processes required for shaping various components of household appliances. Its robust design and high tonnage capacity ensure the capability to handle diverse materials with precision.

Servo Feeder:

The servo feeder is a critical component designed for seamless material feeding. Its precision and adaptability to different coil specifications contribute to the accuracy required in producing components for household appliances. The intelligent servo system enables dynamic adjustments, ensuring consistent feeding and reducing setup times.

Straightener:

A high-precision straightener is incorporated to eliminate material distortions and ensure uniform flatness. This component is crucial in maintaining the quality of the stamped parts. The adjustable rollers provide meticulous control, addressing variations in material thickness and enhancing the overall reliability of the production process.

Decoiler:

The decoiler is responsible for unwinding and supplying the press line with material coils. Its efficient design, equipped with features like automatic tension control and coil loading trolley, streamlines the material handling process. This results in reduced downtime and increased overall productivity.

Impact on Household Appliance Production:

The integration of this comprehensive production line significantly enhances the manufacturing process of household appliances:

Precision and Consistency:

The advanced servo system in the feeder, combined with the high-precision straightener, ensures the production of components with tight tolerances, meeting the exacting standards required in household appliance manufacturing.

Efficiency and Throughput:

The seamless coordination between the press machine, servo feeder, straightener, and decoiler optimizes the overall production workflow. High-speed processing capabilities and automated features contribute to increased throughput, meeting the demands of large-scale production.

Material Versatility:

The production line's adaptability to various materials, including metals and alloys, allows for the manufacturing of a diverse range of components used in different household appliances.

Reduced Scrap and Waste:

The precision in stamping and material handling, coupled with intelligent control systems, minimizes material wastage and reduces scrap. This contributes to cost savings and environmental sustainability.

In conclusion, the implementation of a comprehensive press line with a press machine, servo feeder, straightener, and decoiler brings about a transformative impact on the production of household appliances. The amalgamation of precision, efficiency, and material versatility positions this integrated system as a cornerstone in meeting the evolving demands of the household appliance manufacturing industry.